All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the surface finish options available for aluminum profiles and how do they impact performance and aesthetics?

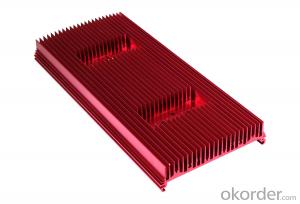

There are several surface finish options available for aluminum profiles, including anodizing, powder coating, and polishing.

Anodizing is a common finish that creates a protective layer on the surface of the aluminum. It improves corrosion resistance and durability while also providing a range of color options. This finish can enhance the aesthetics of the profiles, giving them a sleek and modern appearance.

Powder coating is another popular finish that involves applying a dry powder to the aluminum surface and then curing it under heat. This finish offers excellent durability, weather resistance, and color options. It can greatly enhance the appearance of the profiles, providing a smooth and uniform finish.

Polishing is a surface treatment option that involves buffing the aluminum profiles to create a shiny and reflective surface. This finish enhances the aesthetics, giving the profiles a high-end and luxurious look. However, it may not offer as much protection against corrosion as anodizing or powder coating.

Overall, the choice of surface finish for aluminum profiles greatly impacts both their performance and aesthetics. It is important to consider the specific requirements of the application, such as durability, corrosion resistance, and desired appearance, in order to select the most suitable finish option.

How does the availability of various aluminum profile shapes affect their usability in different industries?

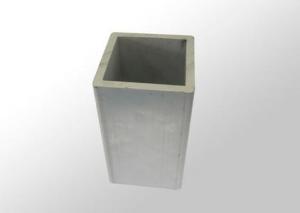

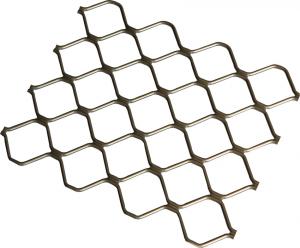

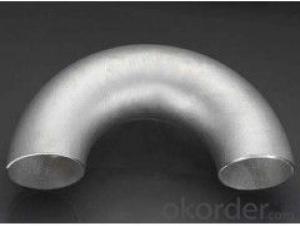

The availability of various aluminum profile shapes significantly impacts their usability in different industries. Different profile shapes offer specific structural properties and design flexibility that cater to the unique requirements of various applications. For instance, industries requiring lightweight structures may benefit from using hollow or lightweight aluminum profiles. On the other hand, industries needing high strength and load-bearing capabilities might opt for thick-walled or reinforced aluminum profiles. The availability of a wide range of shapes allows industries to choose profiles that best suit their specific needs, ensuring optimal performance and efficiency in their respective applications.

What is the lifespan of aluminum profiles in various applications?

The lifespan of aluminum profiles in various applications can vary depending on factors such as environmental conditions, maintenance practices, and the specific application itself. However, in general, aluminum profiles have a long lifespan and are known for their durability and resistance to corrosion. With proper care and maintenance, aluminum profiles can last for decades in applications such as construction, transportation, and manufacturing.

Wholesale Aluminum Profiles from supplier in Belize

We understand the unique requirements of the Belize market and strive to provide customized solutions to meet your specific needs. Whether you are in need of standard Aluminum Profiles or specialized profiles for unique applications, we have the capabilities to fulfill your requirements.

Our team of experts is dedicated to providing exceptional customer service and support. We are committed to delivering timely and accurate sales quotations, ensuring that you have all the information you need to make informed decisions. Our technical support team is also available to assist you with any questions or concerns you may have regarding our Aluminum Profiles products.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to offer a convenient one-stop solution for all your Aluminum Profiles procurement needs. We have a strong supply chain network and can ensure prompt delivery of your orders. Additionally, we adhere to strict quality control measures to ensure that our products meet the highest standards.

Whether you are working on residential, commercial, or industrial projects in Belize, we are here to support you. Contact us today to learn more about our Aluminum Profiles products and services and how we can assist you in your projects.

Our team of experts is dedicated to providing exceptional customer service and support. We are committed to delivering timely and accurate sales quotations, ensuring that you have all the information you need to make informed decisions. Our technical support team is also available to assist you with any questions or concerns you may have regarding our Aluminum Profiles products.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to offer a convenient one-stop solution for all your Aluminum Profiles procurement needs. We have a strong supply chain network and can ensure prompt delivery of your orders. Additionally, we adhere to strict quality control measures to ensure that our products meet the highest standards.

Whether you are working on residential, commercial, or industrial projects in Belize, we are here to support you. Contact us today to learn more about our Aluminum Profiles products and services and how we can assist you in your projects.