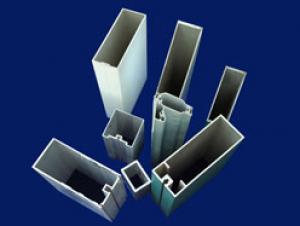

Architectural Aluminum Profiles - Aluminum Product Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ALUMINUM PRODUCT ALUMINUM PROFILES

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: How is the aluminum alloy profile series divided?

- According to alloy composition.1 pure aluminum, such as 1100,2 series aluminum alloy3 Series al Mn alloys, such as 3003, 3A214 series Al Si alloy5 Series Al Mg alloy6 series Al Mg Si alloy, such as 606360617 Series Al Zn Alloy8 lines, others9 line standby

- Q: Are aluminum profiles suitable for automotive heat exchangers?

- Yes, aluminum profiles are suitable for automotive heat exchangers. Aluminum offers several advantages that make it an ideal material for heat exchanger applications in automobiles. Firstly, aluminum has excellent thermal conductivity, which means it can efficiently transfer heat from one medium to another. This property allows aluminum heat exchangers to effectively dissipate heat generated by the engine, transmission, or other components in the vehicle. Secondly, aluminum profiles are lightweight yet strong, making them a preferred choice in the automotive industry where weight reduction is crucial for improved fuel efficiency and performance. The use of aluminum heat exchangers can contribute to overall weight reduction, leading to better handling, acceleration, and energy efficiency. Additionally, aluminum is highly corrosion-resistant, even in harsh environments, making it suitable for automotive applications. This resistance to corrosion ensures the longevity and reliability of the heat exchangers, reducing maintenance and replacement costs. Furthermore, aluminum profiles can be easily manufactured and formed into complex shapes, allowing for customized designs that fit specific automotive requirements. This flexibility in design enables efficient use of available space and maximizes the heat exchange surface area, enhancing overall performance. In conclusion, aluminum profiles are well-suited for automotive heat exchangers due to their excellent thermal conductivity, lightweight yet strong characteristics, corrosion resistance, and flexibility in design. These qualities make aluminum an ideal choice for effectively managing heat in vehicles, contributing to improved performance, fuel efficiency, and durability.

- Q: What are the recycling capabilities of aluminum profiles?

- Aluminum profiles have excellent recycling capabilities. They can be easily recycled without losing their quality or properties. The recycling process involves melting the profiles down, removing any impurities, and then casting them into new shapes or products. This recycling process can be repeated indefinitely, making aluminum profiles a highly sustainable and eco-friendly material.

- Q: What is the price of fluorocarbon coated aluminum profiles, please?

- I don't know what kind of series you needBy the tonAluminum ingot price + fluorocarbon spraying priceThe price of aluminium ingot is about 15000RMB/T nowFluorocarbon three coated roughly 20000RMB/T.The so-called series profiles are just its widthHow many tons of materials are used in a specific project?The density of aluminum is 2700KG/m3With aluminum, but also processing costsWhen purchasing aluminum materials, the packing accounts for 3~5%. of the total aluminum material. Do you see kraft paper or plastic film packaging?

- Q: Does aluminum alloy profile conduct electricity?

- Aluminum conducts well, and aluminium alloys must also be electrically conductive. But aluminum alloys contain impurities such as silicon and magnesium

- Q: This question asks if aluminum profiles can be used in cold weather conditions and if they maintain their properties in such environments.

- <p>Yes, aluminum profiles are suitable for use in cold climates. Aluminum is a durable material with excellent resistance to corrosion and weathering, which includes maintaining its integrity in low temperatures. It does not rust or degrade significantly in cold conditions, making it a reliable choice for construction and other applications in cold climates. However, it's important to consider the specific alloy and any protective coatings or treatments that may be necessary to ensure optimal performance in extreme cold.</p>

- Q: What are the different types of surface coatings for aluminum profiles?

- There are several different types of surface coatings that can be applied to aluminum profiles, each with their own unique characteristics and benefits. 1. Anodizing: Anodizing is a popular coating method that involves creating a protective oxide layer on the surface of the aluminum. This layer not only enhances the appearance of the profile but also improves its resistance to corrosion, wear, and scratches. Anodized aluminum profiles can be further enhanced through color dyeing or other finishing techniques. 2. Powder coating: Powder coating is a dry finishing process that involves applying a powdered coating material to the aluminum profile. The powder is electrostatically charged and then applied to the profile, after which it is heated to form a durable and attractive coating. Powder coating offers excellent protection against scratches, UV rays, and chemical damage, making it a popular choice for outdoor applications. 3. Liquid paint coating: Liquid paint coatings can also be applied to aluminum profiles. This method involves spraying or dipping the profile into a liquid paint solution, which is then cured to form a tough and durable finish. Liquid paint coatings offer a wide range of color options and can be customized to achieve specific aesthetic requirements. 4. PVDF coating: Polyvinylidene fluoride (PVDF) is a high-performance coating material that provides exceptional resistance to weathering, fading, and corrosion. PVDF coatings are typically applied through a liquid paint process and can be used to achieve long-lasting and vibrant finishes on aluminum profiles, especially in architectural applications. 5. E-coating: Electrocoating, also known as electrophoretic deposition (EPD), involves immersing the aluminum profile in a bath of paint or coating solution and applying an electric current to deposit the paint uniformly onto the surface. E-coating provides excellent coverage and adhesion, making it suitable for complex-shaped profiles. It also offers good corrosion resistance and can be used as a primer before applying other coatings. Overall, the choice of surface coating for aluminum profiles depends on the specific requirements of the application, including desired appearance, durability, corrosion resistance, and environmental factors. Each type of coating has its own advantages and limitations, so it is important to carefully consider these factors before making a selection.

- Q: What are the different machining options available for aluminum profiles?

- There are several machining options available for aluminum profiles, including milling, drilling, tapping, turning, and sawing. These processes can be used to create various shapes, sizes, and features on the aluminum profiles, allowing for customization and precise fabrication. Additionally, advanced techniques such as CNC machining and laser cutting can also be employed for more complex and intricate designs.

- Q: The company must tender, but it needs material certification, but what do not know exactly?

- Enterprise legal person business license, China Quality Association approved, the national industrial product production permit, 9001 certificate, a copy of tax registration certificate. Surely that will be enough

- Q: For example, 80*80 square tube 2.0mm thick. Or 38*25 square tube, 0.8mm thick, how to calculate the rice weight? Please tell the specific formula, urgent

- Length (you want to count the number of meters) * width (square tube expansion size) * high (wall thickness) * density (you this square tube material density, aluminum alloy gold density is more complex, generally in 2650~2750Kg/m3)1m * (0.08 * 4) * * 2750kg/m 0.002=0.00064m fand fand =1.76KGThen you 80*80 wall thickness of 2 square tubes, one meter is 1.76 kilogramsWindows and doors exchange group (228021644) hope to help you!

Send your message to us

Architectural Aluminum Profiles - Aluminum Product Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords