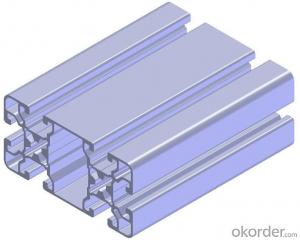

Mill Aluminum Extrusion Profiles Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Management Certification: ISO 9001:2008

Temper: O,F, H112,T4,T5,T6 and T8

Hardness: according to the alloy status

Specifications

1Aluminum alloy tube :AA3003/MOD/3005MOD/4343/7072/4104 etc

2,Temper: H14/24 etc.

3,For Radiator/Inter/oilcoolerEvaporator etc

1. Aluminum tube material for intercooler:

AA3003/3003+Zn/3003MOD/3004/3005/3005MOD/7072/4343/+zn/4045/+zn/4104/4004,etc

Per customer special requirement

Core alloy & Clad Alloy

3. Thickness Range:0.8mm≤T≤1.7MM (per customer special req.)

4.Width Range:10mm≤W≤1380mm

Product/Service (We Sell): | Aluminum coil, Aluminum foil, Aluminum plate non-cladded or cladded alloy) for

|

6. Packaging:

Per customer special requirement

Mark brazing side/non-braze side, water side

Clockwise /anticlockwise, eye to sky/eye to horizon

Cutting with paper core/aluminum core/steel core

Seaworthy Wooden Pallet standard; aluminum coils

- Q: What are the various finishes or coatings that can be applied to aluminum profiles to enhance their appearance, durability, or functionality?

- <p>Aluminum profiles can be coated with a variety of options to improve their aesthetic appeal, corrosion resistance, and performance. These include anodizing, which creates a protective oxide layer; powder coating, offering a wide range of colors and textures; electrophoretic coating, known for its smooth finish; and thermal spraying, which involves applying a coating through a high-velocity flame. Other options are painting, which can be done in various colors, and polishing, which gives a shiny finish. Each coating option has its specific benefits and applications, depending on the requirements of the project.</p>

- Q: How do you ensure proper weatherproofing with aluminum profiles?

- To ensure proper weatherproofing with aluminum profiles, there are several key measures that can be taken. Firstly, it is important to select high-quality aluminum profiles that are specifically designed for weather resistance. These profiles should be treated with a suitable finish or coating that provides protection against corrosion and weather elements. Next, proper installation techniques should be followed to ensure a tight and secure fit. This includes ensuring that the profiles are correctly aligned and joined together using appropriate fasteners or adhesives. Any gaps or openings between the profiles should be sealed with weatherproofing materials such as silicone or rubber gaskets to prevent water or air infiltration. In addition, it is crucial to pay attention to the design and construction of the aluminum profiles. This involves incorporating features like sloped surfaces, drip edges, and drainage systems to facilitate water runoff and prevent pooling or accumulation. Adequate provisions should also be made to address thermal expansion and contraction, which can affect the weatherproofing performance of the profiles. Regular maintenance is another important aspect in ensuring long-lasting weatherproofing. Periodic inspections should be conducted to identify any signs of wear, damage, or deterioration in the profiles or their weatherproofing elements. Any issues should be promptly addressed through repairs or replacement to maintain the integrity of the weatherproofing system. Overall, by selecting quality aluminum profiles, following proper installation techniques, incorporating suitable design features, and conducting regular maintenance, one can ensure proper weatherproofing with aluminum profiles and enhance their durability and performance against weather elements.

- Q: Are aluminum profiles suitable for noise barriers?

- Yes, aluminum profiles are suitable for noise barriers. Aluminum is a lightweight and durable material that can effectively reduce noise transmission. It is often used in the construction of noise barriers due to its ability to absorb and reflect sound waves, helping to minimize noise pollution in various environments. Additionally, aluminum profiles can be easily customized and installed, making them a practical choice for noise barrier applications.

- Q: This question asks for methods to prevent aluminum profiles from rusting during the storage and transportation phases.

- <p>To prevent rusting of aluminum profiles during storage and transportation, follow these steps: 1. Keep the profiles dry and clean, avoiding contact with moisture and corrosive substances. 2. Store them in a cool, dry place, away from direct sunlight and heat sources. 3. Use protective packaging, such as plastic wrapping or anti-corrosion paper, to shield the profiles from moisture and contaminants. 4. Ensure proper ventilation in storage areas to prevent condensation. 5. Avoid stacking profiles directly on the ground; use pallets or racks to elevate them and allow air circulation. 6. Regularly inspect the profiles for signs of corrosion and address any issues promptly. By implementing these measures, you can significantly reduce the risk of rusting during storage and transportation.</p>

- Q: Are aluminum profiles suitable for high-traffic areas?

- Yes, aluminum profiles are suitable for high-traffic areas. Aluminum is a durable and lightweight material that can withstand heavy use and frequent movement. It is resistant to corrosion and can maintain its structural integrity even in high-traffic environments. Additionally, aluminum profiles can be designed to meet specific safety and aesthetic requirements, making them an ideal choice for areas with a large volume of foot traffic.

- Q: Are aluminum profiles capable of being tailored to fit the unique specifications of a construction project?

- <p>Yes, aluminum profiles can be customized to meet specific requirements of a building project. They offer versatility and flexibility, allowing for adjustments in size, shape, and design. Manufacturers can produce aluminum profiles with varying thicknesses, lengths, and finishes to suit the project's structural and aesthetic needs. Customization may include specific bends, cuts, or holes to ensure compatibility with other building components. This adaptability makes aluminum profiles a popular choice for various construction applications, from window frames to structural supports.</p>

- Q: What are the water-resistant properties of aluminum profiles?

- Aluminum profiles possess excellent water-resistant properties due to their inherent corrosion resistance. The aluminum surface forms a thin oxide layer that acts as a protective barrier against moisture and prevents water penetration. This makes aluminum profiles highly resistant to rust, rot, and degradation caused by water exposure, making them ideal for various applications in outdoor and wet environments.

- Q: How can I control the hardness of 6063 aluminum profile at 6-9 degrees?

- Two 、 soft burning treatment:2.1 purpose:Materials for stretching and stretching include rolling materials, extrusion materials and forging materials:Casting - Hot Processing - cold processing - finished materialIn the process of hot or cold processing processing, material processing hardening, the strength increases or lead to work hardening, the strength increases or lead to reduced processing. In order to eliminate the work hardening, for cold working before or after the application of heat treatment is soft burning treatment. Its purpose is to make use of the material is needed.2.2 classification:Due to the different conditions of soft burning:2.2.1 part of soft burning: only part of the work hardening is eliminated, the treatment temperature is below the recrystallization temperature, the actual temperature depends on the strength, and the higher the strength, the lower the treatment temperature2.2.2 completely soft burning: treatment temperature in the recrystallization temperature or slightly higher, so that the material recrystallization, and completely eliminate the work hardening, also make the strength to the lowest stateThere is time and soft burning:2.2.3 soft burning before cold or cold start process, soft burning treatment added, usually completely soft burning, its purpose in the recovery process, and make the next function more smoothly, and the control of the organization, in order to fit for the final product requirements.2.2.4 ultimate soft burning: the main purpose is to adjust the final strength level of the finished product, that is, to adjust the chain3 processing common sense

- Q: This question asks for guidance on selecting the appropriate aluminum profile for a construction project.

- <p>To choose a suitable aluminum profile for your building project, consider the following: First, assess the structural requirements such as load-bearing capacity and span. Second, consider the aesthetic preferences and the desired finish or color. Third, evaluate the environmental conditions the profile will be exposed to, such as weather resistance and corrosion. Fourth, consult with suppliers or manufacturers for technical specifications and recommendations. Fifth, ensure compliance with building codes and standards. Finally, factor in the cost and availability of the profiles. It's often helpful to consult with engineers or architects who can provide expert advice tailored to your specific project needs.</p>

- Q: How do aluminum profiles perform in terms of vibration resistance?

- Aluminum profiles are known to have excellent vibration resistance properties. The inherent characteristics of aluminum, such as its lightweight nature and high strength-to-weight ratio, contribute to its ability to dampen vibrations effectively. Aluminum profiles can absorb and dissipate energy generated by vibrations, reducing the risk of structural damage and ensuring the integrity of the overall system. Furthermore, aluminum profiles can be designed with various geometries and cross-sectional shapes, allowing for enhanced stiffness and rigidity. This improved structural stability helps in minimizing the transmission of vibrations throughout the profile, resulting in reduced resonance and vibration amplification. In addition to these inherent properties, aluminum profiles can be further enhanced through various methods, such as extrusion processes and surface treatments. Extrusion processes can shape the aluminum profiles to specific configurations, optimizing their vibration resistance capabilities. Surface treatments, such as anodizing or powder coating, can provide an additional layer of protection against corrosion and wear, further enhancing the longevity and performance of the profiles. Overall, aluminum profiles excel in terms of vibration resistance due to their lightweight nature, high strength-to-weight ratio, and the ability to be customized for specific applications. These qualities make them an ideal choice for a wide range of industries, including automotive, aerospace, and construction, where vibration control is crucial for maintaining product performance and safety.

Send your message to us

Mill Aluminum Extrusion Profiles Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords