Aluminum Expanded Metal Sheets - Aluminium Plate and Slab with Price in Warehouse with Stocks Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

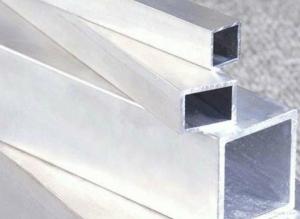

1.Structure of Product Description

We are come from CNBM INTERNATIONAL CORPORATION, our mainly products are as follows: aluminum sheet, aluminuim coil, aluminium composite panel, aluminium sandwich panel, aluminum ceiling etc. we can also provide the raw material for producing the above items, please feel free to contact us for detailed quotation, thanks in advance. sheet are widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series,etc. The detailed grade are as follows: 1010,3003, 3005, 3105, etc.

The temper is include H14, H12, H22, H44,O,F TEMPER ,etc.

2. Main features of the product

a. Competitive price

b. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1250mm*2500mm,at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year

USA, japan, UAE, Vietnam, Canada, etc.

What is your mainly products?

---Normally finish aluminium sheet, aluminum casting coil, etc.

- Q: Are aluminum sheets suitable for beverage cans?

- Indeed, beverage cans can be made from aluminum sheets. The beverage industry heavily relies on aluminum due to its exceptional qualities. This material is renowned for being lightweight and resistant to corrosion. Moreover, it acts as an effective shield against light, oxygen, and moisture, thereby ensuring the beverage's quality and freshness are preserved. In addition, aluminum is highly malleable, enabling the creation of cans with diverse shapes and sizes. Furthermore, it is worth noting that aluminum is recyclable, making it an environmentally conscious option. In summary, aluminum sheets perfectly fulfill the functional and sustainability criteria, rendering them the perfect choice for beverage cans.

- Q: What is the reflectivity of 101 aluminum sheets?

- The reflectivity of 101 aluminum sheets can vary depending on a few factors such as the surface finish, thickness, and any additional coatings or treatments applied to the sheets. Generally, aluminum has a high reflectivity, especially in the visible light spectrum. It can reflect around 80% to 90% of visible light, making it a popular material for reflective surfaces, mirrors, and various lighting applications. However, it is essential to note that the exact reflectivity of 101 aluminum sheets may differ based on specific manufacturing processes or variations in the material properties.

- Q: Does anyone know anything about the value of aluminum can(beer, soda, etc.) pull tabs? I have heard a rumor that the tabs are worth more than the cans and that a gallon jug of tabs can be sold at recycling centers for several hundred dollars.Anyone know if this is really true?

- This Site Might Help You. RE: value of aluminum can pull tabs? Does anyone know anything about the value of aluminum can(beer, soda, etc.) pull tabs? I have heard a rumor that the tabs are worth more than the cans and that a gallon jug of tabs can be sold at recycling centers for several hundred dollars.Anyone know if this is really true?

- Q: Is it possible to recycle aluminum sheets while maintaining their quality?

- <p>Yes, aluminum sheets can be recycled without damaging their quality. The recycling process for aluminum is highly efficient, and it retains its properties even after multiple recycling cycles. Aluminum recycling involves melting the scrap material, which requires only 5% of the energy needed to produce new aluminum from raw materials. This process results in minimal loss of material, and the recycled aluminum maintains its strength and durability, making it suitable for various applications just like new aluminum.</p>

- Q: How do aluminum sheets compare to other metals?

- Aluminum sheets have several advantages when compared to other metals. Firstly, aluminum is very light in weight, making it an ideal choice for applications where weight is a concern, such as in the aerospace industry. Additionally, aluminum is highly resistant to corrosion, which means it can withstand exposure to moisture and chemicals without deteriorating. This makes aluminum sheets suitable for outdoor use and in environments with high humidity or corrosive substances. Moreover, aluminum has excellent conductivity, both thermal and electrical. This makes it a popular choice for heat sinks, electrical enclosures, and other applications that require efficient heat dissipation or electrical conduction. Furthermore, aluminum sheets can be easily shaped and formed, giving them versatility in various manufacturing processes. They can be bent, cut, welded, and machined with relative ease, making them highly adaptable to different design specifications. In terms of cost, aluminum is generally more affordable compared to other metals like steel or copper. This makes it a cost-effective option for many industries, especially for large-scale production or projects with budget constraints. However, it is important to note that aluminum sheets may not be suitable for applications that require high strength or extreme temperatures, as aluminum has lower strength and melting point compared to certain other metals. In such cases, metals like steel or titanium may be more appropriate. In summary, aluminum sheets offer a combination of lightweight, corrosion resistance, good conductivity, versatility, and affordability that makes them a preferred choice in many industries. However, the specific requirements of a project or application should be considered to determine if aluminum sheets are the best fit or if another metal would be more suitable.

- Q: Are aluminum sheets suitable for electrical transformers?

- Indeed, electrical transformers can certainly make use of aluminum sheets. Aluminum, being a highly conductive material, presents numerous benefits when employed in transformers. Primarily, its electrical resistance is lower in comparison to other materials such as copper, enabling efficient transmission of electrical energy. Consequently, this leads to reduced energy losses and enhanced overall performance. Furthermore, aluminum possesses the advantage of being lightweight, rendering it easier to handle and install. Moreover, it is also more economical than copper, thus making it the preferred option for extensive transformer applications. All in all, aluminum sheets offer a dependable and effective resolution for electrical transformers.

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Indeed, it is possible to bend or form aluminum sheets without causing cracks or breaks; however, this outcome is contingent upon the thickness of the sheet as well as the bending or forming technique employed. Aluminum, being an exceptionally pliable material, can be easily manipulated into various shapes without fracturing. Nevertheless, if the sheet is excessively thin or if the bending or forming procedure lacks carefulness and precision, there is a possibility of cracks or breaks occurring. To mitigate this risk, it is imperative to utilize appropriate tools and methods, such as a bending brake or a rolling machine, and to ensure that the sheet is not subjected to excessive force or stress during the process. Furthermore, annealing the aluminum sheet prior to bending or forming can enhance its flexibility and diminish the likelihood of cracking. Ultimately, with the correct approach and necessary precautions, it is feasible to successfully bend or form aluminum sheets without encountering cracks or breaks.

- Q: Can aluminum sheets be used for outdoor applications?

- Yes, aluminum sheets can be used for outdoor applications. Aluminum is a highly durable and corrosion-resistant material, making it suitable for various outdoor uses such as roofing, siding, and decorative cladding. It is also lightweight, which makes it easier to handle and install. Additionally, aluminum can be coated or painted to enhance its weather resistance and aesthetics, further increasing its suitability for outdoor applications.

- Q: How do aluminum sheets compare to steel sheets in terms of strength?

- Aluminum sheets and steel sheets differ in terms of strength. Steel is generally stronger than aluminum, as it has a higher tensile strength, meaning it can withstand greater forces without breaking or deforming. Steel sheets are commonly used in applications that require high strength and durability, such as construction, automotive manufacturing, and aerospace. On the other hand, aluminum sheets offer a good balance between strength and weight. While aluminum is not as strong as steel, it is significantly lighter, which makes it advantageous in certain applications where weight reduction is a priority, such as the manufacturing of aircraft and vehicles. Additionally, aluminum sheets have excellent corrosion resistance, making them suitable for outdoor or marine environments. Ultimately, the choice between aluminum and steel sheets depends on the specific requirements of the application, considering factors like strength, weight, durability, and corrosion resistance.

- Q: What is the elongation of aluminum sheets?

- The elongation of aluminum sheets denotes the extent to which the sheets can stretch or deform before breaking or tearing. It serves as a gauge of the material's ductility or its capability to elongate without fracturing. The elongation of aluminum sheets may differ depending on variables like alloy composition, tempering, and manufacturing techniques employed. As a general rule, aluminum sheets exhibit a notable elongation percentage, ranging from 15% to 40%. This implies that they can be bent, shaped, or stretched to a certain degree without compromising their structural integrity. The elongation of aluminum sheets emerges as a vital characteristic to contemplate in scenarios where the material must endure deformation or be molded into intricate forms.

Send your message to us

Aluminum Expanded Metal Sheets - Aluminium Plate and Slab with Price in Warehouse with Stocks Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords