Aluminum Sheets for Cargo Trailers - Best Price Aluminium Sheet and Slab in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum sheet aluminum plate and aluminium slab are all widely used in the field of construction field and dec field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,O,H114,etc.

2. Main features of the product

a.Competitive price

b. Shortest service.

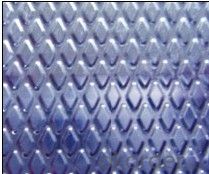

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1250mm*2500mm,at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually standard is GB3880-2006 or others.

What is the width range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normalis around 5 tons/each size.

How many tons did you export in one year

USA, England, UAE, Vietnam, Canada, etc.

What is your mainly

---Normally they are aluminum sheet,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: How does the surface finish of aluminum sheet affect its cleaning requirements?

- The surface finish of aluminum sheet plays a significant role in determining its cleaning requirements. The different surface finishes available for aluminum sheet, such as mill finish, brushed finish, or anodized finish, can impact how dirt, grime, and other contaminants adhere to the surface. In general, smooth and polished surface finishes like brushed or anodized are more resistant to dirt and stains, making them easier to clean. These finishes have a lower surface roughness, which creates fewer areas for dirt particles to adhere to. As a result, they can be cleaned more effectively with gentle cleaning solutions or even just water and a soft cloth. On the other hand, aluminum sheets with a mill finish or a rougher surface may require more intensive cleaning methods. The higher surface roughness of these finishes can create more areas for dirt and grime to get trapped, making it harder to remove them with simple cleaning techniques. In such cases, more aggressive cleaning solutions or abrasive cleaning tools might be necessary to remove stubborn stains or dirt particles. It is important to note that the specific cleaning requirements for aluminum sheet also depend on the type and intensity of the contaminants present. For example, if the aluminum sheet is exposed to harsh chemicals or corrosive substances, special cleaning methods may need to be employed to ensure complete removal and avoid any potential damage. In summary, the surface finish of aluminum sheet directly affects its cleaning requirements. Smoother and polished finishes are generally easier to clean due to their lower surface roughness, while rougher finishes may require more intensive cleaning methods. Understanding the surface finish of aluminum sheet is crucial in determining the most appropriate cleaning techniques to maintain its appearance and functionality.

- Q: This question asks for a method to determine the quantity of aluminum sheets required for a specific project.

- <p>To calculate the amount of aluminum sheets needed for a project, first determine the area that needs to be covered. Measure the length and width of the surface in question. Multiply these two dimensions to get the total area in square units (e.g., square feet or square meters). Next, consider the thickness and specific requirements of the aluminum sheets, as this may affect the number of sheets needed. Finally, divide the total area by the coverage area of one aluminum sheet (which can be found from the supplier or calculated if you know the dimensions and thickness of a single sheet). Round up to the nearest whole number to ensure you have enough material for your project. Always account for waste and additional material for cuts or adjustments.</p>

- Q: Explain the pros and cons of utilizing aluminum sheets in the construction of car body panels.

- <p>Aluminum sheets offer several advantages for car body panels, such as reduced weight, which can improve fuel efficiency and handling. They also have high resistance to corrosion, enhancing the vehicle's durability. Additionally, aluminum is easier to recycle, contributing to environmental sustainability. However, there are downsides, including higher cost compared to steel, which can affect the vehicle's price. Aluminum is also less malleable, making it more challenging to repair after accidents, potentially leading to higher repair costs. Furthermore, aluminum's lower strength compared to steel can necessitate thicker panels to achieve the same structural integrity, which may offset some of the weight savings.</p>

- Q: This question asks about the key factors to consider when buying aluminum sheets, including material properties, thickness, surface finish, and other relevant details.

- <p>When purchasing aluminum sheets, consider the following specifications: 1) Alloy type, which determines properties like strength and corrosion resistance; 2) Thickness, measured in millimeters, affecting the sheet's durability and application; 3) Width and length, which should match your project requirements; 4) Surface finish, such as mill finish, anodized, or painted, which impacts aesthetics and protection; 5) Temper, indicating the hardness and formability of the sheet; 6) Certifications, ensuring the sheet meets industry standards; 7) Supplier reputation and customer reviews for quality assurance. These factors will help you select the right aluminum sheet for your specific needs.</p>

- Q: Are aluminum sheets suitable for construction applications?

- Yes, aluminum sheets are suitable for construction applications. Aluminum is a lightweight and durable material that is corrosion-resistant, making it ideal for various construction projects. It is commonly used for roofing, siding, and wall cladding, as well as in structural applications like beams and columns. Additionally, aluminum sheets offer excellent thermal and electrical conductivity, further enhancing their suitability for construction purposes.

- Q: So I got this stainless steel ring but I took it to this place and apparently its not stainless it's aliminum bc of how light it is but it's really hard so how could it be aluminum?

- Aluminum is a quite soft metal, but so is gold. It is true that aluminum is light in weight but magnesium is even lighter and is common enough that a ring could be made of it. Metals can be made harder by adding small amounts of other metals or even by the way it is heat treated. .

- Q: Are aluminum sheets suitable for chemical storage containers?

- Aluminum sheets are generally not suitable for chemical storage containers. While aluminum is known for its corrosion resistance, it can still react with certain chemicals, leading to degradation of the container and potential contamination of the stored substance. Additionally, aluminum is a relatively soft metal and may not provide adequate strength and durability for long-term storage of hazardous chemicals. It is advisable to use materials specifically designed for chemical storage, such as high-density polyethylene (HDPE), polypropylene (PP), or stainless steel, which offer superior chemical resistance and structural integrity.

- Q: Are aluminum sheets suitable for aerospace fuel tanks?

- Aerospace fuel tanks can indeed utilize aluminum sheets. In the aerospace industry, aluminum is widely employed because of its lightweight yet robust characteristics. Its strength-to-weight ratio is commendable, rendering it an ideal choice for fuel tanks that must endure the forces of flight while minimizing the aircraft's overall weight. Moreover, aluminum's resistance to corrosion is pivotal for aerospace fuel tanks, considering their exposure to diverse fuels and environmental conditions. Furthermore, aluminum's ease of fabrication and widespread availability make it a cost-efficient option for aerospace applications. In summary, aluminum sheets are a fitting material for aerospace fuel tanks due to their strength, lightweight nature, corrosion resistance, and cost-effectiveness.

- Q: Calculate the mass in grams of Iodine (I2) that will react completely with 20.4 g of aluminum to form aluminum oxide (AlL3)

- actually the guy before me did it right but made a mistake at one point 0.07 mole is the # of moles of Al which needs to be changed to moles of product, and then back to find mole of iodide. once thats found then you can use the MW to change it to grams.

- Q: Can 101 aluminum sheets be welded?

- Yes, 101 aluminum sheets can be welded. Aluminum, including 101 aluminum alloy, is commonly used in welding due to its excellent weldability. It is important to note that proper welding techniques and equipment should be used to ensure a successful weld.

Send your message to us

Aluminum Sheets for Cargo Trailers - Best Price Aluminium Sheet and Slab in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords