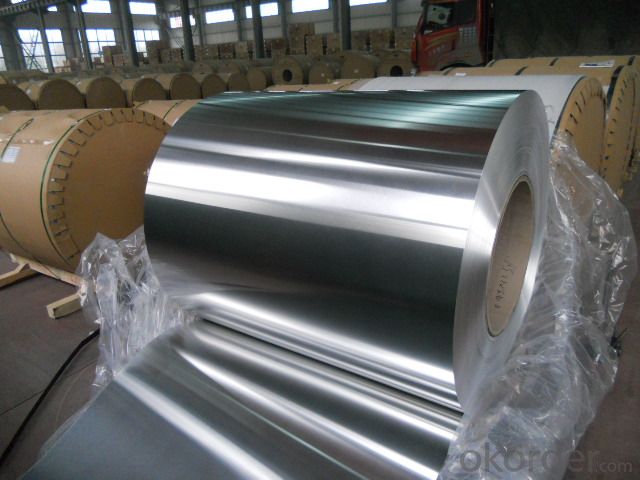

Swirl Brushed Aluminum Sheets for Construction Usage 1100 1060 1070 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are one of the largest aluminum producer in China, and we also use of aluminum rod, billets, rod, foils, sheet, circles, embossed coil etc.We have produced Aluminum Coils over 10 years, and we have good reputation of the price and quality in North part of China

| Aluminum Coil/Sheet | ||||||||

| Main Specification | ||||||||

| Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) | |||||||

| AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | ||||||||

| AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | ||||||||

| AA8xxx(AA8011, AA8006 etc.) | ||||||||

| Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 | |||||||

| Thickmess | 0.01mm-100mm | |||||||

| Width | 30mm-1700mm | |||||||

| Standard | GB/T 3880-2006/ASTM | |||||||

| Special specification is available on customer's requirement | ||||||||

1.Tolerance: thickness tolerance +/-1.5%, width tolerance +/-1mm

2.Application and Usage:

Building Material , Insulation, Shoes &Tents Eyes,Corner Beads,Automotive Industrial, POP Can Bottle and Cap,Deep-Proceeding Case,light industry, TV back board,Street Sign, PP caps, Cell mask and so on.

3.Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

4.Mechenical Property:

Chemical Composite and Mechanical Property could meet the requirements of GB/T, ASTM, ENAW, JIS Standard

5.Packing:First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

- Q: What is aluminium oxide sheet?

- The aluminum oxide plate is placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, and electrolysis is carried out under certain conditions and applied current. Anodized aluminum plate on the surface of the formation of alumina thin layer, its thickness is 5~20 microns, hard anodized film up to 60~200 microns.

- Q: why is it gd and what are common aluminium compounds??? thx

- It's quite expensive to make aluminum, whereas it's quite cheap to melt it down and reuse it.

- Q: What is the thickness of an aluminum sheet?

- The thickness of an aluminum sheet can vary depending on its specific application and desired properties. Standard aluminum sheet thicknesses can range from 0.2 millimeters (0.008 inches) to several millimeters (0.1 inches or thicker).

- Q: Does aluminum sheet require special handling during transportation?

- Transporting aluminum sheets requires special handling due to their lightweight nature and susceptibility to damage if mishandled. To prevent scratching, bending, or denting, it is necessary to take specific precautions. Packaging and securing the sheets in a manner that restricts movement and offers sufficient protection against impacts is crucial. Furthermore, it is important to transport aluminum sheets separately from heavy objects or materials to avoid potential damage caused by their weight. In conclusion, ensuring the safe transportation of aluminum sheets necessitates giving them special care and attention.

- Q: What is the typical weldability of aluminum sheets?

- Aluminum sheets have good weldability due to their high thermal conductivity and low melting point.

- Q: What are the different methods of punching aluminum sheets?

- Various techniques are employed to punch aluminum sheets, each possessing unique advantages and limitations. Presented below are some of the most commonly used methods: 1. Manual Punching: The most fundamental approach involves the use of handheld punch tools to manually create holes or shapes in aluminum sheets. It is suitable for small-scale projects and uncomplicated designs, yet it may be time-consuming and less accurate when compared to alternative methods. 2. Mechanical Punching: Mechanical punching machines utilize a mechanical press equipped with a punch and die set to puncture holes or form shapes in aluminum sheets. Such machines offer higher production rates, improved accuracy, and repeatability. This method is well-suited for medium to large-scale projects. 3. CNC Punching: Computer Numerical Control (CNC) punching machines employ computer programming to control the motion of the punch and die set. This technique enables the creation of intricate shapes, patterns, and multiple holes in a single operation. CNC punching provides exceptional precision, efficiency, and versatility, making it highly sought after in industrial settings. 4. Laser Punching: Laser punching merges laser cutting and punching technologies. A high-powered laser beam heats and softens the aluminum sheet, followed by a mechanical punch that forms the desired hole or shape. Laser punching delivers superior precision, speed, and the capability to work with various materials and thicknesses. It is commonly employed in the automotive and aerospace industries. 5. Waterjet Punching: Waterjet punching involves using a high-pressure stream of water mixed with abrasive substances to cut through aluminum sheets. This method is ideal for cutting intricate shapes and thick materials. It boasts exceptional precision, minimal material distortion, and the ability to work with a diverse range of materials. The choice of punching method depends on factors such as design complexity, required precision, production volume, and budgetary considerations. It is crucial to consider these factors and seek guidance from professionals to determine the most appropriate punching method for a specific application involving aluminum sheets.

- Q: What are the standard tolerances for aluminum sheets?

- The standard tolerances for aluminum sheets vary depending on the specific industry and application. However, some commonly accepted tolerances for aluminum sheets include thickness tolerances, flatness tolerances, and width and length tolerances. Thickness tolerances refer to the allowable variation in the thickness of an aluminum sheet. These tolerances can range from +/- 0.005 inches to +/- 0.010 inches, depending on the grade and thickness of the sheet. Flatness tolerances specify the degree of flatness or deviation from a perfectly flat surface that is acceptable for an aluminum sheet. Flatness tolerances can range from a few thousandths of an inch to a few hundredths of an inch, depending on the specific requirements of the application. Width and length tolerances define the allowable variation in the dimensions of an aluminum sheet. These tolerances can be specified in terms of +/- inches or as a percentage of the sheet's width or length. Generally, width and length tolerances for aluminum sheets are in the range of +/- 0.25 to +/- 0.50 inches. It is important to note that these standard tolerances are subject to change and can vary depending on the specific industry, customer requirements, and the capabilities of the manufacturer. Therefore, it is always recommended to consult the manufacturer or industry-specific standards to determine the precise tolerances for aluminum sheets in a particular application.

- Q: Are the aluminum sheets suitable for electrical conductivity applications?

- Yes, aluminum sheets are suitable for electrical conductivity applications.

- Q: Are aluminum sheets suitable for signage applications?

- Indeed, signage applications can benefit from the use of aluminum sheets. Due to its lightweight nature and durability, aluminum proves to be an ideal material for outdoor signs that must endure diverse weather conditions. Its resistance to rust and corrosion guarantees the sign's longevity. Moreover, aluminum sheets can be effortlessly customized and shaped into various sizes, enabling the creation of versatile and imaginative signage options. Furthermore, aluminum serves as an exceptional material for digital printing, producing top-notch graphics and images. All in all, aluminum sheets present remarkable durability, versatility, and aesthetic allure, cementing their status as a favored choice for signage applications.

- Q: Are aluminum sheets suitable for insulation purposes?

- Yes, aluminum sheets are suitable for insulation purposes. Aluminum is a good conductor of heat, so it can effectively reflect and block thermal energy. Additionally, aluminum sheets are lightweight, corrosion-resistant, and easy to install, making them a popular choice for insulation applications.

Send your message to us

Swirl Brushed Aluminum Sheets for Construction Usage 1100 1060 1070 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords