Sublimation Aluminum Sheet Stock

Sublimation Aluminum Sheet Stock Related Searches

Anodized Aluminum Sheet Stock Aluminum Sheet Stock Thickness Aluminum Stock Aluminum Sheet Stock Sizes Aluminum Laminated Shim Stock Aluminum Frame Stock Aluminum Shim Stock Sheets Aluminum Shim Stock Laminated Aluminum Shim Stock Aluminum Engraving Stock Aluminum Stock Material Aluminum Box Stock Aluminum Price Stock Aluminum Square Stock Stock Aluminum Aluminum Screen Frame Stock Aluminum Strip Stock Aluminum Lathe Stock Aluminum Solid Square Stock Aluminum Metal Stock Aluminum Bedded Stock Aluminum Manufacturers Stock Aluminum Tubing Stock Anodized Aluminum Stock Aluminum Pipe Stock 1 Inch Square Aluminum Stock Aluminum Chassis Stock Extruded Aluminum Stock Aluminum Extrusion Stock Aluminum Machining StockSublimation Aluminum Sheet Stock Supplier & Manufacturer from China

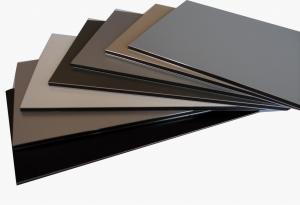

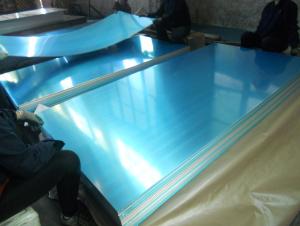

Sublimation Aluminum Sheet Stock is a type of metal material that has been specifically treated to allow for the transfer of ink or dye onto its surface through a sublimation process. This unique property makes it an ideal choice for creating high-quality, durable, and vibrant images on various products such as signs, plaques, and promotional items.The application of Sublimation Aluminum Sheet Stock is vast, as it can be used in various industries for different purposes. It is commonly utilized in the production of custom-made items like personalized gifts, corporate branding materials, and even in the creation of artwork. The usage scenarios for this product range from small businesses to large-scale manufacturers, catering to the needs of both individual customers and bulk orders.

Okorder.com is a reputable wholesale supplier of Sublimation Aluminum Sheet Stock, boasting a large inventory that caters to the diverse demands of its clientele. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Sublimation Aluminum Sheet Stock they provide is of the highest standard, making it a reliable choice for businesses looking to incorporate this innovative material into their product offerings.

Hot Products