Master Forge Aluminum Grill Sheets - PE Color Coated and Stucco Embossed Aluminum Coils (0.2~0.7mm)

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

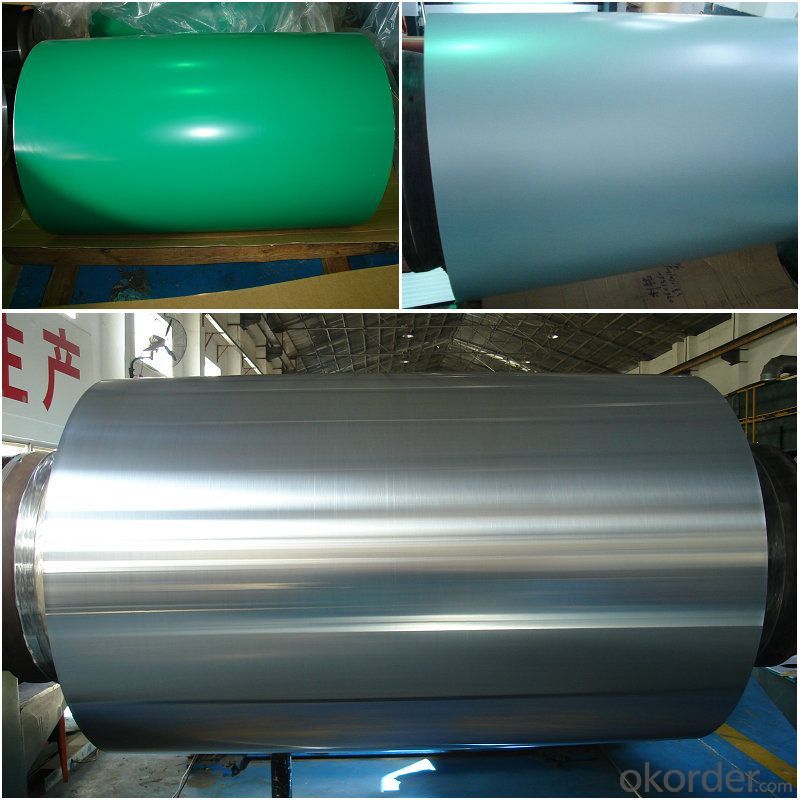

1. Structure of PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm

Color coated and embossed aluminum coils are widely used for decorations, freezer, refrigerator, central air conditioning and ventilation nozzles, mechanical equipment enclosures and so on.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

3. PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm Images

4. Specification of PE Color Coated and Stucco Embossed Aluminum Coils with Thickness 0.2~0.7mm

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Are the aluminum sheets suitable for manufacturing architectural roof systems?

- Yes, aluminum sheets are suitable for manufacturing architectural roof systems. Aluminum is a popular choice for roofing materials due to its durability, lightweight nature, and resistance to corrosion. These qualities make it ideal for withstanding various weather conditions, including high winds, rain, and snow. Additionally, aluminum can be easily fabricated and shaped into different forms, allowing for flexibility in design and installation. It is also a sustainable and environmentally friendly option as it can be recycled. Overall, the use of aluminum sheets in manufacturing architectural roof systems offers numerous benefits and is a suitable choice for this application.

- Q: Can the aluminum sheets be used for soundproofing applications?

- Yes, aluminum sheets can be used for soundproofing applications. Aluminum is a lightweight and highly reflective material that can effectively block and absorb sound waves. When used in soundproofing applications, aluminum sheets can help reduce noise transmission and create a quieter environment. They can be installed as barriers, panels, or even as part of a composite material to enhance soundproofing properties. Additionally, aluminum sheets are durable, corrosion-resistant, and easy to maintain, making them suitable for long-term use in various soundproofing applications.

- Q: I want to make a part using molten aluminum with a hole through the middle and would like to use a steel rod to do this. Would the bar stick to the aluminum when it cools and not be able to be removed? If so is there so type of coating I can use so it can be removed?

- Aluminium and iron are pretty incompatible materials, they don't form an alloy I don't think, so it is unlikely they would stick. Also, both metals will get an oxide layer on the surface which should keep them separate. Try it! If the finished part does stick, try heating the aluminium then dip the steel rod in some ice water.

- Q: how to produce aluminium sheet circle?

- As for the process, you can use punch.. as for professional machines, for example, stationary press in open type, mechanical press/ single-point press. The material you say is neither big nor small, blanking…(cutting them into sheet circle you want) you can add an uncoiling if it’s coil stock: open-type inclinable press, four-point press,ect. It’s not certainly accurate) punch, oil press, double , four-column hydraulic (oil) press,etc. it needs about 315T,(estimated value, closed type single, blank material cutting (cutting into square ) 2, it contains sheet metal forming technology, crank press: 1: straight side two : 1, but the components you said is simple, only two steps.

- Q: How does the thickness tolerance of aluminum sheet affect its usability?

- The thickness tolerance of aluminum sheet plays a significant role in determining its usability. The thickness tolerance refers to the acceptable deviation from the specified thickness of the sheet. It is typically expressed as a range or a plus/minus value. A tighter thickness tolerance ensures that the aluminum sheet meets the desired specifications consistently. This is crucial for applications where precise dimensions are required, such as in aerospace, automotive, and construction industries. In these applications, even a slight deviation in thickness can negatively impact the performance and functionality of the product. For instance, in aircraft manufacturing, the thickness tolerance of aluminum sheets used for structural components is highly critical. A thin sheet might compromise the structural integrity, while a thicker sheet could lead to excess weight, affecting fuel efficiency. Similarly, in the automotive industry, precise thickness tolerance is essential for ensuring compatibility and fitment of various components. On the other hand, a looser thickness tolerance can be acceptable for applications where precise dimensions are not as critical. For example, in general fabrication, signage, or decorative purposes, a wider thickness tolerance may not significantly affect the usability or appearance of the aluminum sheet. Additionally, the cost of manufacturing aluminum sheets with tighter thickness tolerances is typically higher due to increased precision and quality control measures. Therefore, the required level of tolerance should be balanced with the intended use and cost considerations. In conclusion, the thickness tolerance of aluminum sheet directly affects its usability, particularly in industries requiring precise dimensions. It is essential to select the appropriate tolerance level to ensure the sheet meets the required specifications, maintaining the desired performance and functionality of the final product.

- Q: Are 101 aluminum sheets suitable for architectural louvers or sunscreens?

- Yes, 101 aluminum sheets are suitable for architectural louvers or sunscreens. They possess excellent strength, durability, and corrosion resistance, making them ideal for outdoor applications. Additionally, their lightweight nature allows for easy installation and maintenance.

- Q: What are the different methods of cutting aluminum sheet?

- Some of the different methods of cutting aluminum sheet include using shears, bandsaws, jigsaws, circular saws, laser cutting, and waterjet cutting.

- Q: What are the different types of coatings available for aluminum sheets?

- There are several different types of coatings available for aluminum sheets, each offering unique properties and benefits. 1. Anodized Coating: Anodizing is a popular coating method that involves immersing the aluminum sheet in an electrolyte bath and passing an electric current through it. This process creates a durable and corrosion-resistant layer of oxide on the surface of the sheet. Anodized coatings can come in various colors and offer excellent abrasion resistance. 2. Powder Coating: Powder coating involves applying a dry powder to the aluminum sheet and then curing it under heat. This coating method provides a durable, uniform, and attractive finish. Powder coatings are available in a wide range of colors and textures and offer excellent resistance to chipping, scratching, and UV fading. 3. Paint Coating: Aluminum sheets can also be coated with liquid paint. This method provides versatility in terms of color choices and finishes. Paint coatings offer good resistance to weathering, impact, and chemicals, but they may not be as durable as anodized or powder coatings. 4. Cladding: Cladding is a process in which a layer of a different metal, such as stainless steel or copper, is bonded to the aluminum sheet surface. This provides added protection, improved aesthetic appeal, and can enhance the sheet's mechanical properties. 5. Laminating: Laminating involves bonding a protective layer, such as a film or sheet, onto the surface of the aluminum sheet. This coating method offers protection against abrasion, UV rays, and chemicals, and can also provide decorative finishes. 6. Organic Coating: Organic coatings, such as polyurethane or acrylic coatings, are applied to aluminum sheets to provide protection against corrosion, weathering, and chemical exposure. These coatings offer flexibility, good adhesion, and a wide range of color choices. Overall, the choice of coating for aluminum sheets depends on the specific requirements of the application, such as durability, corrosion resistance, aesthetic appeal, and cost-effectiveness.

- Q: Can the aluminum sheets be used for manufacturing food storage containers?

- Yes, aluminum sheets can be used for manufacturing food storage containers. Aluminum is a popular choice for food storage containers because it is lightweight, durable, and has excellent thermal conductivity. It can easily be formed into various shapes and sizes, making it suitable for different types of food storage needs. Additionally, aluminum is resistant to corrosion and can be easily cleaned, ensuring the safety and hygiene of the stored food.

- Q: Can aluminum sheets be embossed?

- Yes, aluminum sheets can be embossed. Embossing is a process that creates a raised or sunken design on a material's surface. Aluminum is a versatile material that can be easily manipulated, including being embossed. Embossing aluminum sheets can be done using various methods, such as heat embossing or using embossing tools and machines. The embossing process adds texture and dimension to the aluminum sheets, enhancing their appearance and making them suitable for various applications such as decorative purposes, signage, nameplates, or even for adding texture to automotive or architectural accents.

Send your message to us

Master Forge Aluminum Grill Sheets - PE Color Coated and Stucco Embossed Aluminum Coils (0.2~0.7mm)

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords