Sheets of Aluminum for Sale - Best Price Aluminium Sheet in Warehouse with Stocks

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum sheet and aluminum plate and aluminium slab are all widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,O,H114,etc.

2. Main features of the product

a.Competitive price

b. Shortest service.

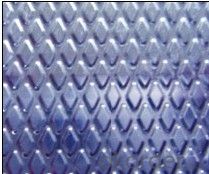

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1220mm*2440mm,1250mm*2500mm,at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year

USA, japan, UAE, Vietnam, Canada, etc.

What is your mainly products?

---Normally finish aluminium sheet, aluminum casting coil, etc.

- Q: Are the aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction due to their excellent corrosion resistance, high strength-to-weight ratio, and durability in harsh marine environments.

- Q: So my new farrier comes out tomorrow and charges $20 more for aluminum shoes and I was wondering why that is? Is one better than the other? My horse is a TB hunter jumper. Tell me what you think :)

- Like others have pointed out aluminum are lighter but more expensive and must be replaced more often, but they are also much lighter. When I am seriously competing I put aluminum shoes on my horses just for the summer show season to take advantage of the lighter weight, then back to steel for the rest of the year (and with steel being as durable as it is I can keep the same pair stored away to be put back on in the fall.) It's your call, its not a HUGE difference but it might help him pick his feet up better.

- Q: This question asks for a comparison of aluminum sheets with other materials regarding their cost and performance.

- <p>Aluminum sheets are generally cost-effective and offer excellent performance compared to many other materials. They are lightweight, which reduces material and transportation costs. They also have high strength-to-weight ratios, making them durable and resistant to corrosion. In terms of performance, aluminum sheets are versatile, used in various industries such as construction, automotive, and aerospace. They conduct heat and electricity well, which is beneficial for applications requiring thermal or electrical conductivity. However, they may be more expensive than some plastics or cheaper metals like steel on a per-unit basis, but their lower weight and durability often offset this cost over time.</p>

- Q: What are the different methods for bending aluminum sheets?

- Depending on the desired outcome and available equipment, there are various techniques for bending aluminum sheets. The following are some commonly used methods: 1. Manual Bending: For smaller projects, the aluminum sheet can be manually bent using a manual brake or bending tool. This can be achieved by hand with the assistance of clamps or a simple bending tool. 2. Press Brake: In industrial settings or for larger-scale projects, a press brake machine is utilized. It applies significant force through a punch and die set to create precise and consistent bends. 3. Roll Bending: To achieve long, continuous bends or curves, the aluminum sheet is passed through a series of rollers in the roll bending method. This technique is commonly employed in the production of cylindrical or conical shapes. 4. Rotary Bending: Thin aluminum sheets are effectively bent into curves using rotary bending. This method involves a rotating roller or wheel along the length of the sheet to create smooth and uniform bends. 5. Heat Bending: Thicker aluminum sheets or complex shapes often require heat bending. The sheet is heated to a specific temperature to enhance its malleability before being bent into the desired shape. It is crucial to consider factors such as aluminum thickness and alloy, desired bend angle and radius, and available equipment when choosing the appropriate bending method. Consulting professionals or referring to specific guidelines is recommended for optimal results.

- Q: Are aluminum sheets resistant to vibration?

- Aluminum sheets, in general, demonstrate resistance towards vibration. Being a lightweight and flexible material, aluminum possesses excellent damping characteristics, enabling it to effectively absorb and dissipate vibrations. Moreover, aluminum exhibits a high strength-to-weight ratio, ensuring its structural integrity remains intact under vibrating conditions. Consequently, aluminum sheets are highly favored in sectors like aerospace, automotive, and construction, where protection against vibrations is crucial. Nevertheless, it is important to acknowledge that the degree of vibration resistance may differ depending on various factors such as the thickness and alloy composition of the aluminum sheet, as well as the intensity and frequency of the vibrations.

- Q: How much weight/people can a 12ft aluminum boat hold?and if anyone knows how much weight can a 6.5hp motor push around

- 12 Ft Aluminum Jon Boat

- Q: Can the aluminum sheets be used in the construction industry?

- Certainly, the construction industry can make effective use of aluminum sheets. Aluminum proves to be a highly adaptable and lightweight material, offering numerous advantages for construction purposes. Its resistance to corrosion makes it especially suitable for outdoor structures and buildings. Roofing, siding, window frames, doors, and other architectural components often incorporate aluminum sheets. Moreover, aluminum's exceptional strength-to-weight ratio enables the creation of sturdy and efficient structures. Its malleability also facilitates easy fabrication and shaping into various forms, allowing for imaginative and groundbreaking designs in construction projects. Overall, aluminum sheets remain a widely favored choice in the construction industry due to their enduring nature, adaptability, and aesthetic appeal.

- Q: What is the typical fatigue strength of aluminum sheets?

- The typical fatigue strength of aluminum sheets can vary depending on several factors such as alloy composition, thickness, manufacturing process, and surface treatment. However, in general, aluminum sheets have a relatively high fatigue strength compared to other materials. Aluminum alloys, especially those used in aerospace and automotive applications, are known for their excellent fatigue resistance. The fatigue strength of aluminum sheets is typically expressed in terms of the stress level (in MPa) at which failure occurs after a certain number of cycles. For aluminum alloys commonly used in structural applications, the fatigue strength can range from around 70 MPa to 150 MPa, depending on the specific alloy and thickness. However, it is important to note that this is a general range, and there can be significant variations based on the aforementioned factors. It is worth mentioning that the fatigue strength of aluminum sheets can be significantly enhanced through various techniques such as heat treatment, alloying, and surface treatments like shot peening or anodizing. These processes can increase the fatigue life and improve the overall performance of aluminum sheets in cyclic loading conditions. In conclusion, the typical fatigue strength of aluminum sheets can be considered relatively high compared to other materials, but it can vary depending on several factors. Proper material selection, along with appropriate processing and surface treatments, can significantly improve the fatigue performance of aluminum sheets.

- Q: Are 101 aluminum sheets suitable for solar panel frames?

- Yes, 101 aluminum sheets are suitable for solar panel frames. 101 aluminum is a commonly used grade of aluminum that is known for its excellent strength and corrosion resistance. These properties make it an ideal material for constructing frames that can withstand the outdoor elements and provide adequate support for solar panels. Additionally, 101 aluminum sheets are lightweight, which is important for easy installation and transportation of solar panels. Overall, 101 aluminum sheets are a suitable choice for solar panel frames due to their strength, corrosion resistance, and lightweight properties.

- Q: I have a set of Chrome Aluminum rims, and two of them have scratches on them. So instead of buying new ones, is it possible to paint them. I was thinking black.

- Can You Chrome Aluminum

Send your message to us

Sheets of Aluminum for Sale - Best Price Aluminium Sheet in Warehouse with Stocks

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords