Aluminium Roofing Sheet for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

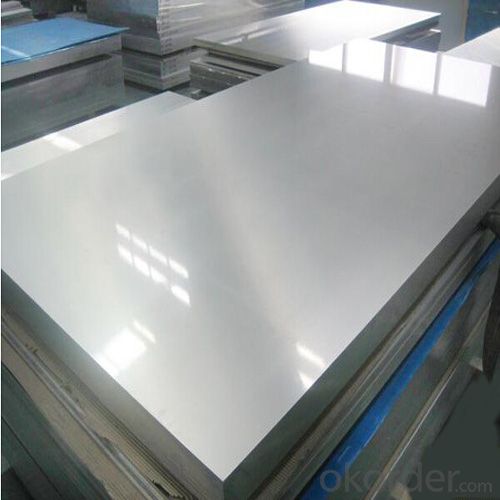

1.Structure of Aluminium Roofing Sheet for Construction Description:

Aluminium Roofing Sheet for Construction are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Aluminium Roofing Sheet for Construction:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

3. Aluminium Roofing Sheet for Construction Images:

4. Mill Finish Plain Aluminum Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process..

- Q: Can aluminum sheets be used for furniture manufacturing?

- Certainly! Furniture manufacturing can make use of aluminum sheets. Aluminum is a highly versatile material that possesses several advantageous properties, making it suitable for the production of furniture. Lightweight, durable, and corrosion-resistant, aluminum can be easily shaped into various sizes and forms. Additionally, aluminum has a sleek and modern appearance, making it a popular choice for contemporary furniture designs. Frames, legs, and other structural components for chairs, tables, shelves, and cabinets can be fashioned from aluminum sheets. The versatility and durability of aluminum make it a viable option for furniture manufacturing, particularly for outdoor or industrial furniture that requires resistance to harsh weather conditions or heavy use.

- Q: How does the surface roughness affect the friction properties of aluminum sheet?

- The friction properties of an aluminum sheet are significantly affected by its surface roughness. When the surface is rough, there are more microscopic peaks and valleys, which can enhance the frictional forces between the sheet and the contacting surfaces. Generally, an increase in surface roughness results in a higher friction coefficient. This occurs because the roughness increases the effective contact area between the aluminum sheet and the opposing surface, leading to more interlocking and adhesion between the two surfaces. Consequently, the resistance to relative motion, or friction, is heightened. Moreover, a rough surface can trap lubricants or contaminants, reducing lubrication efficiency and increasing friction. The roughness of the aluminum sheet also influences the formation and retention of a lubricating film, further impacting the friction properties. It is important to acknowledge that the type of roughness, such as its amplitude, wavelength, and orientation, can also affect the friction properties. For instance, certain surface textures, like grooves or patterns, may facilitate lubricant retention and reduce friction, even with increased roughness. In summary, the friction properties of an aluminum sheet are significantly determined by its surface roughness. A rough surface increases the contact area and adhesion between the sheet and opposing surface, resulting in higher friction coefficients. However, the specific characteristics of the roughness and the presence of lubricants or contaminants can further influence the friction behavior.

- Q: Are aluminum sheets resistant to vibration?

- Yes, aluminum sheets are generally resistant to vibration. Aluminum is a lightweight and flexible material that has good damping properties, meaning it can absorb and dissipate vibrations. Additionally, aluminum has a high strength-to-weight ratio, which allows it to retain its structural integrity even when subjected to vibrations. This makes aluminum sheets a popular choice in industries such as aerospace, automotive, and construction, where vibration resistance is important. However, it is worth noting that the specific resistance to vibration may vary depending on factors such as the thickness and alloy of the aluminum sheet, as well as the intensity and frequency of the vibrations.

- Q: What is the coefficient of friction for aluminum sheets?

- The coefficient of friction for aluminum sheets can vary depending on the specific conditions and surfaces involved.

- Q: Can 101 aluminum sheets be stamped or engraved?

- Yes, 101 aluminum sheets can be stamped or engraved.

- Q: Cooks are warned not to use aluminum cookware when preparing acidic foods. Why?

- Plain okorder /... Hope this helps.

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly or sustainable buildings?

- <p>Yes, aluminum sheets can be used for green building projects. They are lightweight, strong, and durable, which reduces the amount of material needed and the energy consumed in transportation. Aluminum is also 100% recyclable, meaning it can be repurposed without losing quality, reducing waste and the need for new raw materials. Additionally, aluminum has a high reflectivity, which can help in reducing heat absorption and thus lowering cooling costs in buildings. These properties make aluminum a sustainable choice for green building initiatives.</p>

- Q: Can aluminum sheets be used in aerospace industry?

- Aluminum sheets find common usage within the aerospace industry due to their numerous desirable qualities. One of the foremost advantages is their lightweight nature, a critical factor for both aircraft and spacecraft. This characteristic aids in reducing fuel consumption and increasing the capacity for payload. Another significant attribute of aluminum is its exceptional strength-to-weight ratio, which imparts structural integrity to aerospace components. Furthermore, aluminum exhibits high resistance to corrosion, ensuring longevity and durability within harsh environments. Additionally, its commendable thermal conductivity qualifies it for heat dissipation in aerospace systems. Moreover, aluminum boasts easy formability, enabling the manufacturing of intricate shapes and structures. In summary, the versatility, strength, lightness, and corrosion resistance of aluminum make it the material of choice in the aerospace industry for diverse applications, including aircraft frames, fuselage panels, wings, and engine components.

- Q: Are the aluminum sheets suitable for manufacturing architectural column covers?

- Yes, aluminum sheets are suitable for manufacturing architectural column covers.

- Q: Are aluminum sheets suitable for automotive suspension components?

- Yes, aluminum sheets are suitable for automotive suspension components. Aluminum is a lightweight and durable material that offers several advantages for suspension components. Firstly, aluminum sheets are significantly lighter than traditional steel components. This weight reduction can lead to improved fuel efficiency and overall vehicle performance. By reducing the weight of suspension components, the vehicle's handling, acceleration, and braking can be enhanced, resulting in a smoother and more responsive ride. Secondly, aluminum has excellent strength-to-weight ratio, which means it can provide the necessary structural integrity and support for suspension components while still being lightweight. It possesses high tensile strength and stiffness, allowing it to withstand the stresses and forces exerted on suspension components during normal driving conditions. Moreover, aluminum is highly corrosion-resistant, which is beneficial for automotive suspension components that are exposed to various environmental conditions. This corrosion resistance ensures the longevity and durability of the suspension system, reducing the need for frequent repairs or replacements. Additionally, aluminum is easily machinable, allowing for complex and intricate designs that can optimize suspension performance. Its flexibility in shaping and forming enables manufacturers to create suspension components with specific geometries and characteristics to meet the desired performance requirements. In conclusion, aluminum sheets are indeed suitable for automotive suspension components due to their lightweight, high strength-to-weight ratio, corrosion resistance, and machinability. These properties make aluminum a preferred material for suspension components, resulting in improved vehicle performance, fuel efficiency, and overall durability.

Send your message to us

Aluminium Roofing Sheet for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords