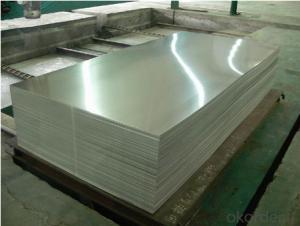

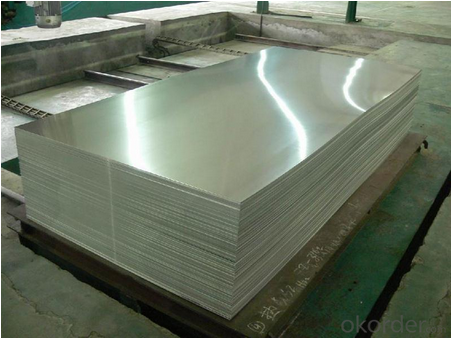

Alloy Aluminium Sheet for Roofting Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 g/m²

- Supply Capability:

- 200000 g/m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Alloy Aluminium Sheet for Roofting Building

Product Parameters

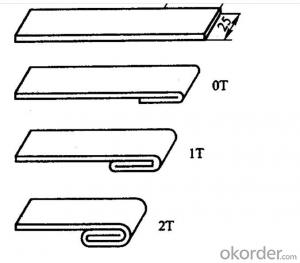

| Alloy Aluminium Sheet for Roofting Building | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

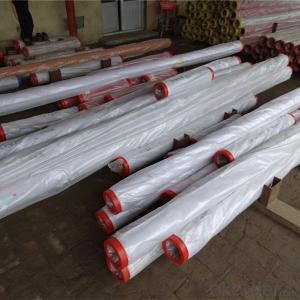

| Packing : Export wooden pallets. The bundle wegiht not exceed 2MT. Loading:by 1x20GP, 1X20GP can load about 18MT | |||||

| Standards:ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

| Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |||||

| Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

| MOQ | 5 tons | ||||

| Payment term: | T/T,L/C | ||||

| Delivery Time | 15 days after 30% T/T payment or receiving L/C copy | ||||

| Kind attention : Specifications can be customized as the customer’s requirements. | |||||

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will b.e sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union,etc

- Q: 3D MAX must set motion for each object. Is there a 3D mechanical design software that can simulate the mechanical movement of the parts?As long as the specified object is motor, coupling, chain, gear, into the simulation, the three-dimensional map of the motor shaft will rotate, and drives the coupling, keys, gear for the corresponding movement, rather like 3D Max that is the true state of motion to each object design movement performance of this machine combination?

- Commonly used simulation parts mechanical movement software, ADAMS and SolidWorks Motion module.ADAMS is a professional CAE software, the automatic dynamic analysis of mechanical system (Automatic Dynamic Analysis of Mechanical Systems), the software is the U.S. Mechanical Dynamics Inc (Mechanical Dynamics Inc.) (now part of MSC) the development of virtual prototype analysis software. ADAMS software uses an interactive graphical environment, and part library, library, library capacity constraints, the mechanical system to create fully parametric geometric model, Lagrange equation method of multi rigid body dynamics in the solver using system equations, statics kinematics and dynamics analysis, the virtual machine system, output displacement, speed, acceleration and reaction force. The simulation of ADAMS software can be used to predict the mechanical performance, range of motion, collision detection, peak load, and input load of finite elements.The Motion module of SolidWorks constructs the coordination relation through the constraint form among parts, and completes the simulation of motion between parts.

- Q: In the design of large machinery, it is to design the parts first, the assembly drawings as well

- First of all, the transmission mechanism must be defined first, and then the strength of the transmission system must be calculated, and then the actual size, gear modulus and so onThen draw parts, assemble, assemble problems, and then change parts

- Q: Force calculation is in the component diagram, the size of the component is obtained by force, and if you don't draw the parts first, how do you draw the general plan?How do you calculate the force of a part if you draw the part diagram first and don't know the size relation between the parts?

- First draw a diagram, determine the location of each part, then draw the parts drawing, and finally the general drawing

- Q: What are the main functions of CAE software commonly used in the design of mechanical products or parts?

- Finite element analysis, structural motion analysis, interference checking, dimensional chain analysis.

- Q: I am an ordinary graduate, two jobs to me, one is non-standard automatic design work, but the first half of the assembly in the workshop, and then to design. There is also a mechanical component CAD draftsman. After that, you can do part design. May I ask which job will have a future for you?

- How do you say, non standard salary is relatively high, but the difficulty is also great, what can relate to the requirements of the design experience, not newcomers can do. What about a draftsman? It's easy to get started after graduation, but it's easier to work long hours without a nonstandard design. Of course, but also depends on what specific units. Consider yourself. Hope to adopt

- Q: Write the XX in the code for the detail column of the assembly drawingThe company's standard clerk says that the standard number or pattern code can only be used in the code bar. The part XX of my presentation is a part of the assembly drawing, which is a non-standard part. I wonder what standard to fill in Is it the material standard? But the material, Q235B, has been written in the material column.

- A part of an assembly drawing. If it is a standard part, fill in the name of the part and the standard code. If it is a nonstandard part, fill in the part name and the code specified by the company.As you mentioned, it should be the standard staff who can only fill out the part code, which is the code number specified by your company. Drawing design, the non-standard parts using the company's parts code.

- Q: Can the bearings used in the design of mechanical equipment be used as part drawings?

- (4459.7 GB/T 1998) for the following provisions: (1) the basic regulations and general characteristics of drawing, drawing, drawing in the various provisions of symbols, rectangular wire frames and contour lines are drawn with thick lines. When drawing a rolling bearing, the size of the rectangular frame and the outline of the outer frame should be consistent with the shape dimension of the rolling bearing (found in the manual) and the same proportion as the drawing. In the cutaway view, when drawing the rolling bearings by the universal drawing and the characteristic drawing, the section symbols (section lines) are not drawn. When drawing with the prescribed drawing method, the rolling body of the bearing does not draw a section line, and each ring can be painted in the same line section with the same direction and spacing, as shown in Figure a. Such as bearings with other parts or accessories (such as eccentric sleeve, tight sets, retaining rings, etc.), the profile line should be in line with the ring profile in different directions or different intervals, as shown in Figure B. Omission is not allowed in drawing without misunderstanding.

- Q: I am a bachelor degree in industrial design and have been sitting here for two months now, 20The feeling is still not understand, not figure painting, other colleagues are busy, I could not ask, do not know how to do, give me a leading figure today, let me figure it out on my own, I draw more and more have no confidence, I do not know because many mechanical components, do not know how to do.. Tired ~ ~ mechanical aspects of the great God, I pointed to the Ming road! Thanks

- Do not understand to communicate with people ah ~ you can truthfully and under the leadership of the reaction, find a master under guidanceA mechanical design is learning by doing, the school learned to pick it up, in addition to learn how to use the design manual, design experience for reference to others

- Q: What are the main principles of mechanical principles and mechanical parts design?

- 7. part surface quality requirements and corrosion protection requirements;8. cost factors;......There are many other factors.

- Q: What kind of software is used in the design of machine parts?

- No, most, only the more, the most suitable for you is your most.If you usually design only 100 of the following parts, use SOLIDWORKIf it is under 1000, using proe is goodMore than 10000, then you use CATIAAs for UG, a little embarrassed, suspended in midair.

Send your message to us

Alloy Aluminium Sheet for Roofting Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 g/m²

- Supply Capability:

- 200000 g/m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches