Aluminum Sheet and Coil for Roofing Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

If your roof exhibits any of the above symptoms—or if your roof is simply old—The Aluminum Company will gladly examine your roof as a courtesy to help you determine whether it can be repaired or needs to be replaced. This service call is without any cost or obligation to you.

3. Feature of Aluminum

A new Owens Corning or CertainTeed roof will protect and beautify your home for many years to come. And it will add substantial resale value to your biggest lifetime investment, your home. Choose your roof’s level of durability - 15, 20 or 30 years

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

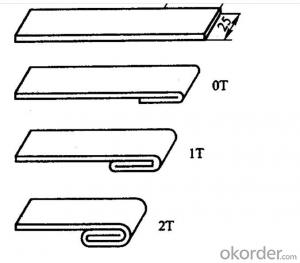

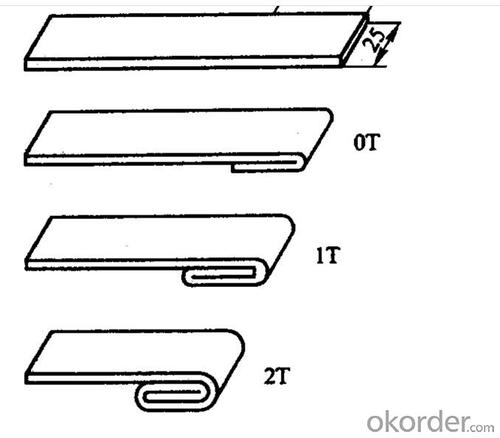

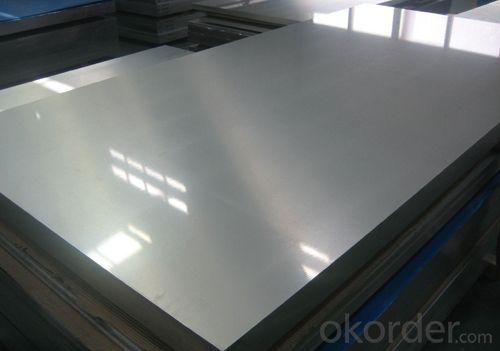

5. Image of Aluminum

6. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: How to measure the thickness of aluminum coil at real time? In what areas can the sensor be used?

- I suggest that you use the laser displacement sensor for real-time measurement of the thickness of aluminum coil. ZLDS100 can exactly measure the change value of aluminum coil thickness through simple technique in the thickness measurement project, which can help judge the production phase and status.

- Q: 1mm how much is one square meter for aluminum rolls?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet.

- Q: Can aluminum coils be used in automotive body panels?

- Automotive body panels can indeed utilize aluminum coils. Being both lightweight and corrosion-resistant, aluminum proves to be a suitable material for automotive purposes. The employment of aluminum coils in body panels yields numerous benefits, such as enhanced fuel efficiency owing to the reduced vehicle weight, improved handling and maneuverability, and increased durability. Moreover, aluminum boasts high recyclability, rendering it an environmentally conscious alternative for automotive production. Numerous automakers have already begun integrating aluminum coils into their vehicles, and this trend is anticipated to persist as the industry aims for lighter and more environmentally sustainable automobiles.

- Q: Can aluminum coils be used in cryogenic applications?

- Yes, aluminum coils can be used in cryogenic applications. Aluminum has excellent thermal conductivity and low thermal expansion properties, making it suitable for use in extremely low temperature environments. Additionally, aluminum is resistant to corrosion, which is important in cryogenic applications where moisture and other contaminants can cause damage to the coils.

- Q: What is the formula to calculate the wall thickness of aluminum coil?

- Aluminum coil thickness*aluminum coil width*aluminum coil curl*aluminum density (the density of aluminum alloy: 2.73, the density of pure aluminum: 2.71)

- Q: Can aluminum coils be used in low-friction applications?

- Yes, aluminum coils can be used in low-friction applications. Aluminum's low coefficient of friction and excellent thermal conductivity make it a suitable material for various applications where low friction is desired, such as in sliding mechanisms, bearings, and electrical connectors.

- Q: When you are cooking fish? I ran out of aluminum foil, all I have is parchment paper on hand. Does it matter or affect the way the fish gets cooked? Just wondering what the difference is, if any.

- The fish should cook fine in the parchment paper - it could be even better that way.

- Q: Why does the heat preservation aluminum roll bend when it is cooled?

- In recent years, because the iron sheet in the heat preservation industry does not have rust prevention effect, so now in the domestic aluminum sheet has fully replace iron sheet.

- Q: How are aluminum coils protected against corrosion?

- Aluminum coils are protected against corrosion through various methods such as applying protective coatings, anodizing the surface, using corrosion-resistant alloys, and implementing proper maintenance practices.

- Q: Are aluminum coils suitable for electrical grounding applications?

- Indeed, aluminum coils prove to be fitting for electrical grounding applications. Possessing a commendable level of conductivity, aluminum showcases approximately 61% of the conductivity that copper offers. In electrical contexts where conductivity and resistance to corrosion hold significance, aluminum is frequently employed. As a grounding substitute, aluminum coils present a cost-efficient option to copper coils. Furthermore, the lightweight and manageable nature of aluminum coils contribute to their widespread preference for electrical grounding purposes. Nevertheless, it is crucial to guarantee appropriate installation and upkeep to avert any potential predicaments, such as galvanic corrosion, when connecting aluminum with other metals.

Send your message to us

Aluminum Sheet and Coil for Roofing Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords