A255/40/100 Aluminum Bar Grating For Deck Access Stair Tread

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

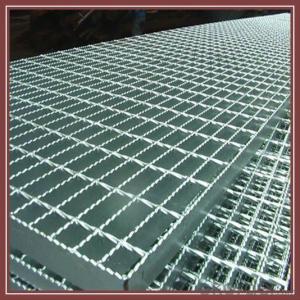

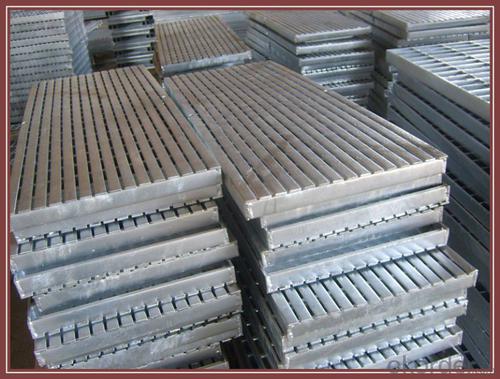

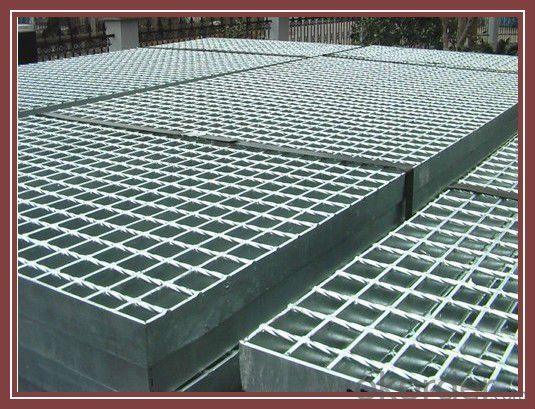

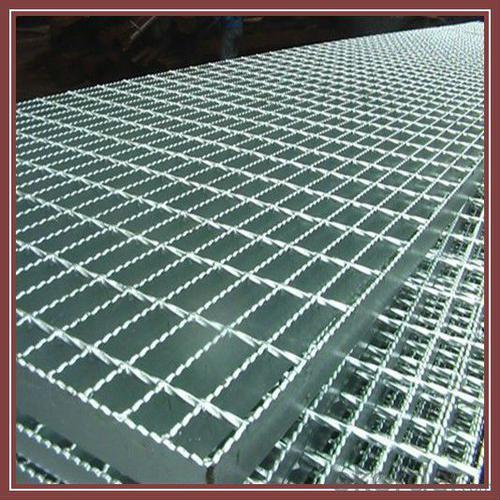

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the typical machinability of aluminum sheets?

- The machinability of aluminum sheets is generally considered to be excellent. Aluminum is known for its relatively low density and softness, which makes it easier to machine compared to other metals. It has good thermal conductivity, allowing for efficient removal of heat generated during machining, and it also has a low melting point, reducing the risk of overheating. Additionally, aluminum has good chip formation characteristics, resulting in easy chip evacuation and reduced tool wear. However, the machinability of aluminum can vary depending on factors such as alloy composition, tempering, and surface finish. Overall, aluminum sheets are widely regarded as being highly machinable.

- Q: What are the advantages of using aluminum sheet in construction?

- There are several advantages to using aluminum sheet in construction. Firstly, aluminum is lightweight, making it easier to handle and transport compared to other materials. Secondly, it is highly resistant to corrosion, which ensures durability and longevity of structures. Additionally, aluminum is a good conductor of heat and electricity, making it suitable for various applications such as electrical wiring. Lastly, aluminum is recyclable, making it an environmentally friendly choice for construction projects.

- Q: As for cast aluminum sheet or wrought one, which one has faster heat conduction?

- 1,duralumin: it's the alloy of aluminum, copper, magnesium, manganese and other metals. it's suitable for compacting by rolling, and it has a higher strength and hardness than common aluminum products. 2, aluminum: it contains many inpurities, is crisp and easy to be smashed.cast aluminum usually is secondary aluminum, and it is produced by remelting the collected old aluminum pots and spoons.3, wrought aluminum: it contains 98% aluminum and 2% or more inpurities, and is comparatively pure aluminum. its soft priority makes it suitable for being pressed into various shapes, aluminum pots,aluminum lunch box,aluminum sheets,aluminum wires,aluminum pipes are all made by wrought aluminum.you will know their defferences from their definition.

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various industrial applications, including shelving. It offers strength and stability while being easy to clean and maintain. Additionally, aluminum's versatility allows for customization and modification to fit specific storage needs.

- Q: What are the different grades of aluminum sheets?

- There are several different grades of aluminum sheets available in the market, each with its own unique properties and uses. The most commonly used grades include 3003, 5052, and 6061. - Grade 3003: This is a non-heat treatable alloy that is highly resistant to corrosion. It is often used in applications where corrosion resistance is essential, such as in packaging, cooking utensils, and chemical equipment. - Grade 5052: This grade is also non-heat treatable and offers excellent corrosion resistance. It is known for its strength and durability, making it suitable for marine applications, transportation equipment, and architectural purposes. - Grade 6061: This is a heat treatable alloy that combines good corrosion resistance with high strength. It is widely used in structural applications, such as in aircraft components, automotive parts, and construction materials. Apart from these grades, there are also other specialized aluminum alloys available, such as 2024, 7075, and 5083, which offer specific properties for particular industries or applications. It is important to consider the specific requirements of your project before choosing a grade of aluminum sheet, as each grade has its own strengths and limitations. Consulting with a knowledgeable supplier or expert can help you determine the most suitable grade for your needs.

- Q: Are aluminum sheets suitable for pharmaceutical applications?

- Aluminum sheets are well-suited for pharmaceutical use, as they possess a range of advantageous properties. Firstly, their lightweight nature and exceptional resistance to corrosion make them an ideal choice for packaging pharmaceutical products. By shielding the contents from external factors like moisture, light, and oxygen, which could potentially compromise the medication's quality, aluminum sheets offer excellent protection. Additionally, aluminum sheets are highly malleable and can easily be molded into different shapes and sizes, allowing for customized packaging designs. Moreover, their availability in various thicknesses provides options for different types of pharmaceutical products, including tablets, capsules, and liquid medications. Furthermore, aluminum sheets boast a remarkable barrier property that effectively prevents the transfer of odors, flavors, and contaminants. This barrier ensures the integrity and safety of the medication throughout its entire shelf life. Furthermore, aluminum is a non-toxic material, guaranteeing that it does not react with drugs or alter their composition. This quality makes it an optimal choice for pharmaceutical applications, where maintaining the purity and stability of the medication is of utmost importance. In conclusion, aluminum sheets are highly suitable for pharmaceutical applications, thanks to their lightweight nature, corrosion resistance, barrier properties, and non-toxic composition. By efficiently safeguarding and preserving pharmaceutical products, they ensure the quality and safety of these crucial medications.

- Q: What is aluminum sheet material L2?

- L2 is the name of the brand of aluminium plate in our country, which is the 1060 brand now!L1 is 1070L2 is 1060L3 is 1050L4 is 1030L5-1 is 1100And LF-21, or 3003, LF-1, or 3004! Wait

- Q: Does exposure to ultraviolet (UV) rays impact the properties or longevity of aluminum sheets?

- <p>Aluminum sheets are generally resistant to UV rays, which means they do not degrade or corrode due to exposure to sunlight or UV radiation. Aluminum has a high reflectivity and can reflect most of the UV rays, minimizing the impact on its surface. However, prolonged exposure can cause a slight change in color, known as patina, which is a natural oxidation process and does not compromise the integrity or strength of the material. Overall, aluminum maintains its properties well under UV exposure, making it a suitable material for outdoor applications.</p>

- Q: Can aluminum sheets be painted or coated with different colors?

- Yes, aluminum sheets can be painted or coated with different colors. Aluminum is a versatile material that can be easily painted or coated to achieve various colors and finishes. The process typically involves pre-treating the surface, applying a primer, and then applying the desired paint or coating. This allows for customization and aesthetic enhancement of aluminum sheets in numerous applications.

- Q: How do you bend aluminum sheets?

- To bend aluminum sheets, you will need a few tools and the right technique. Here is a step-by-step guide on how to bend aluminum sheets: 1. Gather the necessary tools: You will need a metal brake, which is a specialized tool used for bending metal sheets, and a straight edge, such as a ruler or a piece of wood. 2. Measure and mark the bending line: Determine where you want to make the bend on the aluminum sheet and use a measuring tape to mark the line. Make sure the line is straight and accurate. 3. Position the aluminum sheet: Place the aluminum sheet on the metal brake, aligning the marked bending line with the edge of the brake. Ensure the sheet is secure and won't move during the bending process. 4. Adjust the metal brake: Depending on the thickness of the aluminum sheet, adjust the metal brake to the appropriate bending angle. This can typically be done by loosening or tightening the clamps or screws on the brake. 5. Bend the aluminum sheet: Apply pressure on the metal brake, slowly bending the aluminum sheet along the marked bending line. Start from one end and work your way towards the other, ensuring a smooth and even bend. 6. Check the bend: After bending, double-check the angle and alignment to ensure it matches your desired specifications. If necessary, make any adjustments before proceeding. 7. Repeat if needed: If you need to make multiple bends on the aluminum sheet, repeat the process for each one. Take your time and be patient to achieve the desired results. It's important to note that the thickness and type of aluminum sheet may require adjustments to the bending technique. Thicker sheets may need more pressure or multiple passes to achieve the desired bend. Always refer to the specific instructions and recommendations provided by the manufacturer of your metal brake for best results.

Send your message to us

A255/40/100 Aluminum Bar Grating For Deck Access Stair Tread

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords