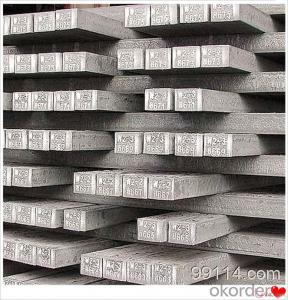

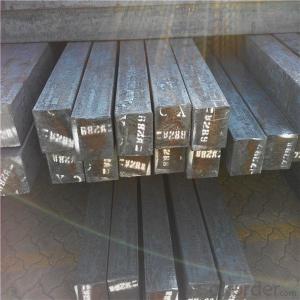

Alloy Steel billets for sale Q195/Q215 China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15672 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Size :100mm to 165mm

Length:6~12meters

Grade: Q195/Q215/Q235/Q275

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the different forging methods used for steel billets?

- Steel billets can be forged using different methods, each with its own advantages and applications. Open Die Forging is a method where the steel billet is shaped between flat dies. This allows for flexibility in design and size, making it suitable for larger and more complex parts that require customization, like shafts, cylinders, and discs. Closed Die Forging, also known as impression die forging, involves shaping the steel billet within a set of dies that contain the desired shape. It is ideal for producing high-precision and complex parts with tight tolerances, such as gears, connecting rods, and crankshafts. Upset Forging is a method that involves increasing the cross-sectional area of the steel billet by compressing it between dies. This is commonly used for creating short-length parts like bolts, screws, and fasteners. Roll Forging uses cylindrical rolls to gradually shape the steel billet into the desired form. It is often used to produce long parts with a consistent cross-section, such as bars, rods, and shafts. Press Forging utilizes a hydraulic or mechanical press to shape the steel billet, providing greater control over the forging process. This method is often employed for manufacturing automotive components, aerospace parts, and tools. Isothermal Forging involves heating the steel billet and the dies to the same temperature, reducing the cooling effect during forging. This allows for greater control over the microstructure and mechanical properties of the final product, making it suitable for producing parts that require high strength and temperature resistance. Each forging method has its own benefits, allowing steel billets to be shaped into a wide range of products with varying complexity, size, and mechanical properties. The choice of forging method depends on factors such as the desired product, material properties, production volume, and cost considerations.

- Q: Can steel billets be used for making cutlery?

- Yes, steel billets can be used for making cutlery. Steel billets are the raw material used in the production of various steel products, including cutlery. The billets are heated and then shaped into desired forms, such as knives, forks, or spoons, through processes like forging or casting. The resulting steel cutlery is known for its strength, durability, and ability to hold a sharp edge. However, it is important to note that the specific type of steel used and the manufacturing processes play a significant role in determining the quality and characteristics of the cutlery.

- Q: What is the role of steel billets in the construction of stadiums and arenas?

- Steel billets play a crucial role in the construction of stadiums and arenas as they are the primary raw material used to manufacture structural steel components. These billets are heated and shaped into various forms, such as beams, columns, and trusses, which provide the necessary support and framework for the overall structure. The high strength and durability of steel make it an ideal material to withstand the heavy loads and forces experienced in these large-scale facilities. Additionally, steel billets can be easily fabricated and assembled on-site, ensuring efficient construction and enabling the creation of complex designs and architectural features.

- Q: How do steel billets contribute to the manufacturing of construction equipment?

- Steel billets contribute to the manufacturing of construction equipment by serving as the raw material that is shaped and formed into different components such as beams, plates, and pipes. These billets are heated and then passed through various processes like rolling, forging, and machining to create the desired shape and size. The strength, durability, and versatility of steel make it an ideal material for construction equipment, ensuring that the machinery can withstand heavy loads, harsh environments, and demanding construction tasks.

- Q: What are the different types of cleaning equipment used for steel billets?

- There are several different types of cleaning equipment that are commonly used for steel billets. These include: 1. Shot blasting machines: Shot blasting is a process that involves propelling small metal or mineral particles at high speed onto the surface of the steel billets. This helps to remove any rust, scale, or other contaminants, leaving the surface clean and smooth. 2. Ultrasonic cleaners: Ultrasonic cleaning involves the use of high-frequency sound waves to agitate a cleaning solution. This helps to remove dirt, oil, and other contaminants from the surface of the steel billets. Ultrasonic cleaners are particularly effective for removing stubborn or hard-to-reach contaminants. 3. Acid pickling tanks: Acid pickling is a process that involves immersing the steel billets in a tank of acidic solution. The acid helps to dissolve any rust, scale, or other contaminants on the surface of the billets. After pickling, the billets are usually rinsed and then dried. 4. Power washers: Power washers, also known as pressure washers, use a high-pressure spray of water to remove dirt, oil, and other contaminants from the surface of the steel billets. This is a particularly effective method for cleaning larger or heavier billets. 5. Mechanical cleaning brushes: Mechanical cleaning brushes, such as wire brushes or abrasive pads, are often used to manually scrub the surface of the steel billets. This helps to remove any loose dirt, rust, or scale. Mechanical cleaning brushes are typically used in conjunction with other cleaning methods. Overall, the choice of cleaning equipment for steel billets depends on factors such as the extent and type of contaminants present, the desired level of cleanliness, and the size and shape of the billets. Different combinations of these cleaning methods may be used to achieve the desired result.

- Q: What are the specifications for tool steel billets used in the tooling industry?

- The tooling industry typically requires tool steel billets to meet specific specifications in order to achieve optimal performance and durability. These specifications encompass various aspects: 1. Alloy Composition: Tool steel billets are composed of specific alloys that provide high hardness, wear resistance, and toughness. Common elements in tool steel include carbon, chromium, vanadium, molybdenum, and tungsten. 2. Hardness: Heat treatment is applied to tool steel billets to attain the desired hardness level, often measured using Rockwell hardness (HRC). The required hardness depends on the tool's application and type. 3. Size and Shape: Tool steel billets are available in different sizes and shapes, such as rectangular or round bars, to accommodate diverse tooling requirements. The dimensions of the billets are selected based on the size and complexity of the intended tool. 4. Surface Finish: Tool steel billets must possess a smooth and clean surface finish to facilitate machining and reduce the risk of defects or flaws in the final tooling product. 5. Tolerance: Billets should be manufactured with precise dimensional tolerances to ensure consistency during the machining and tooling processes. This aids in achieving accurate tool dimensions and minimizing waste. 6. Homogeneity: Tool steel billets must exhibit uniform chemical composition and microstructure throughout to ensure consistent mechanical properties and performance in the final tooling products. 7. Heat Treatment Properties: Billets should possess favorable heat treatment properties, including the ability to be hardened and tempered. This enhances their strength, toughness, and wear resistance. 8. Machinability: Tool steel billets should have good machinability to enable efficient shaping and forming processes during tool manufacturing. This encompasses considerations for cutting forces, chip formation, and surface finish. It is important to note that the specific specifications for tool steel billets may vary depending on the application and type of tool being produced. Manufacturers and tooling experts often collaborate closely to determine the most suitable tool steel specifications for each specific tooling requirement.

- Q: How are steel billets used in the production of oil and gas components?

- Due to their strength, durability, and ability to withstand extreme conditions, steel billets are indispensable in the production of oil and gas components. These billets serve as essential raw materials in various manufacturing processes for creating the equipment and parts required in the oil and gas industry. One notable application of steel billets in the oil and gas sector is their use in manufacturing pipes and casings. These billets are heated and then rolled or forged into seamless or welded pipes, which are utilized for transporting oil and gas from wells to refineries or distribution centers. The high strength of steel billets ensures that these pipes can endure the high pressure and corrosive nature of the substances being transported. Steel billets are also integral to the production of valves, flanges, and fittings, which are critical components in oil and gas infrastructure. These billets are machined or forged into various shapes and sizes to create these components, used for controlling the flow of oil and gas within pipelines or at different stages of the production process. The durability and resistance to corrosion of steel billets make them ideal for these applications, as they can endure the harsh conditions often encountered in oil and gas operations. Moreover, steel billets find utility in the production of drilling equipment such as drill bits, drill collars, and drill pipes. These billets are frequently treated with heat or alloying elements to enhance their strength and wear resistance. The resulting components can withstand the intense forces and abrasion experienced during drilling operations, ensuring efficient and reliable extraction of oil and gas reserves. In conclusion, steel billets play a crucial role in the oil and gas industry by providing the essential raw materials for manufacturing durable and high-performance components. Their strength, durability, and resistance to corrosion make them an ideal choice for the challenging conditions encountered in the production, transportation, and processing of oil and gas.

- Q: How are steel billets priced in the market?

- Steel billets are typically priced in the market based on various factors such as supply and demand dynamics, production costs, and market conditions. The pricing is influenced by factors such as raw material costs, energy prices, transportation costs, and any applicable taxes or duties. Additionally, market participants consider factors like global economic trends, industry forecasts, and geopolitical events that may impact the overall steel market. Ultimately, steel billet pricing is determined through negotiations between buyers and sellers based on these various factors.

- Q: What is the role of steel billets in the production of wire rods?

- Wire rods depend greatly on steel billets for their production. These long, cylindrical metal rods are widely utilized in construction, automotive, and manufacturing industries. To begin the production process of wire rods, steel is melted in either an electric arc furnace or a basic oxygen furnace. Once the desired temperature and composition are achieved, the molten steel is poured into molds, resulting in the formation of steel billets. Steel billets act as semi-finished products that serve as the initial stage in the wire rod manufacturing process. These solid bars of steel, which can be rectangular or round, undergo further processing to be transformed into wire rods. The conversion of steel billets into wire rods commences with a reheating process. The billets are subjected to high temperatures, making them more malleable and easier to manipulate. This reheating process is typically carried out in a reheat furnace. Following reheating, the billets are passed through a series of rolling mills. This reduces their size and shapes them into wire rods. These rolling mills apply a combination of pressure and heat to deform the steel billets, elongating them into long, thin rods. This rolling process also enhances the mechanical properties of the wire rods, such as their strength and flexibility. Once the wire rods are formed, they may undergo additional treatments, including cooling, surface treatments, and quality inspections. These treatments are necessary to meet the specific requirements of different applications. The wire rods can then be further processed into various products, such as wires, cables, reinforcement bars, or other specialized components. In conclusion, steel billets are a critical component in the production of wire rods. They serve as the starting material, undergoing various processing steps, such as reheating and rolling, to achieve the desired shape and properties of wire rods.

- Q: What are the different types of steel billet rolling defects?

- During the rolling process, various defects can arise in steel billets, which can have adverse effects on the final product's quality and integrity. The most commonly encountered types of steel billet rolling defects are as follows: 1. Surface cracks: These are minute cracks that manifest on the billet's surface. They can result from inadequate cooling or excessive rolling pressure. Surface cracks jeopardize the steel's strength and durability. 2. Center cracks: Inner core cracks occur when temperature control during the rolling process is incorrect. Center cracks can lead to structural weaknesses and reduced steel performance. 3. Scalloping: Scalloping refers to the formation of shallow depressions or grooves on the billet's surface. It usually arises due to uneven or improper rolling pressure distribution. Scalloping negatively impacts the steel's appearance and surface quality. 4. Lamination: Lamination defects involve the separation of layers within the billet. They can be caused by the presence of impurities or inclusions in the steel, as well as inadequate heating or rolling conditions. Lamination defects weaken the steel and increase the risk of failure. 5. Wavy edges: Wavy edges occur when the billet's edges become uneven or distorted during rolling. This can be the result of improper alignment or uneven pressure distribution. Wavy edges affect the steel's dimensional accuracy and overall quality. 6. Surface defects: Surface defects encompass scratches, pits, or other imperfections on the billet's surface. They may occur due to insufficient cleaning or handling procedures, as well as improper rolling conditions. Surface defects impact the steel's appearance and surface quality. In conclusion, these steel billet rolling defects hold significant implications for the final product's quality, performance, and safety. Manufacturers must closely monitor the rolling process and implement appropriate quality control measures to minimize the occurrence of these defects.

Send your message to us

Alloy Steel billets for sale Q195/Q215 China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15672 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords