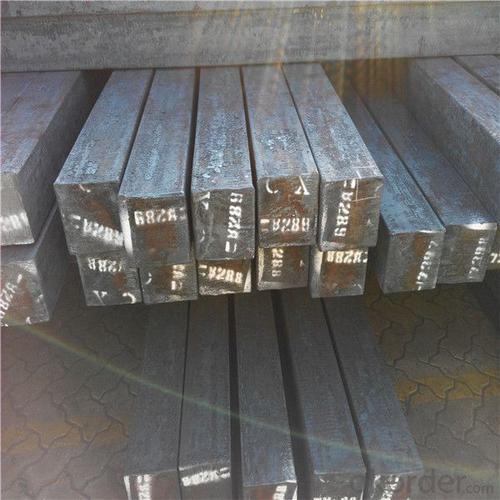

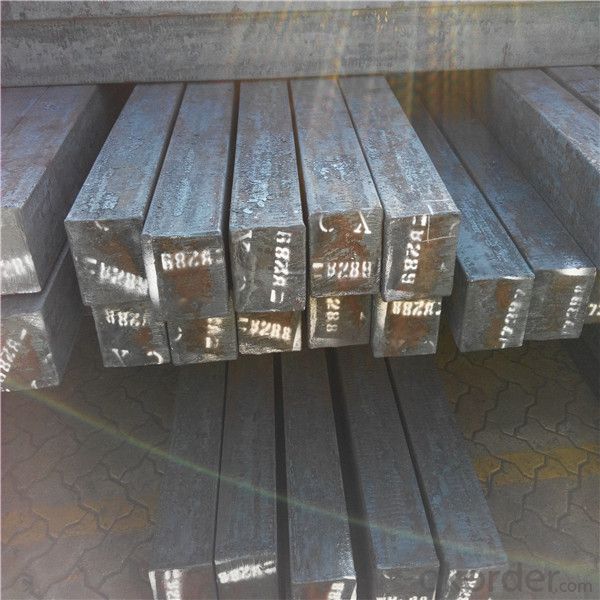

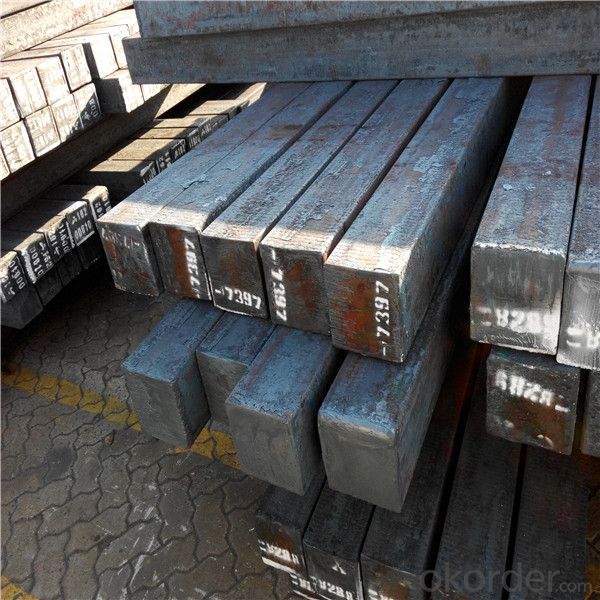

Steel billets Q215 chrome alloy low price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 14950 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still require

a series of shaping and molding procedures such as hot and cold working, milling and cutting before they

are sold in hardware stores, or used for different applications. The unformed billets, however, can be used

in striking currency such as coins and as reserves, similar to gold bars.

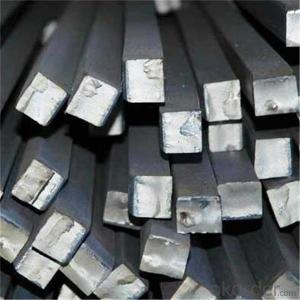

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base

building the support foundation pile manufacturing.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

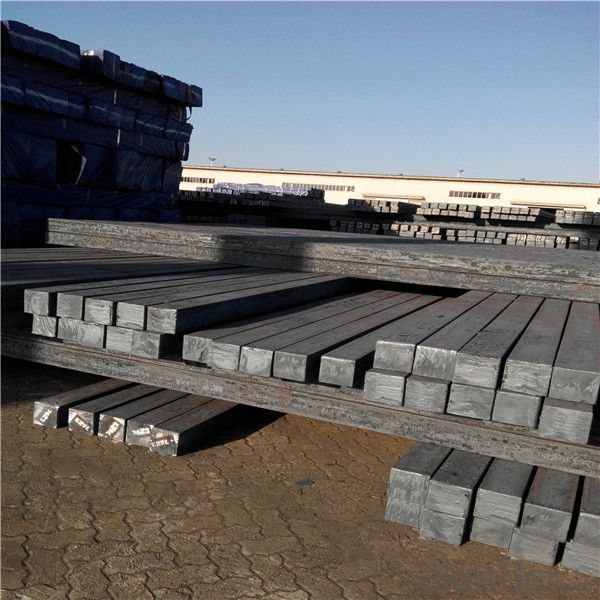

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How are steel billets packaged for shipment?

- Steel billets are typically packaged for shipment in a way that ensures their protection and facilitates easy handling. The packaging process usually involves several steps to guarantee the safe transportation of the billets. Firstly, the steel billets are inspected to ensure they meet the required quality standards. Once approved, they are cleaned and dried to remove any dirt or moisture that could cause corrosion during shipment. Next, the billets are bundled together using steel strapping or wire to secure them in a compact form. This bundling not only prevents the billets from shifting or rolling during transportation but also facilitates easy handling and loading onto trucks or containers. To further protect the steel billets, they are often wrapped in a layer of plastic or paper. This additional layer acts as a barrier against moisture, dust, and other potential contaminants that could damage the billets during transit. Once the billets are bundled and wrapped, they are usually loaded onto pallets or placed in steel crates. This provides stability during transportation and allows forklifts or cranes to easily move and stack the packaged billets. Finally, the packaged steel billets are labeled with relevant information such as the product name, dimensions, weight, and destination. This labeling ensures accurate identification and helps in the efficient handling and delivery of the billets. Overall, steel billets are packaged for shipment in a way that prioritizes protection, ease of handling, and efficient transportation. These packaging measures ensure that the billets reach their destination in optimal condition, ready for further processing or use in various industries.

- Q: What is the average cost of transporting steel billets?

- The average cost of transporting steel billets can vary depending on several factors. These factors include the distance of transportation, the mode of transportation (road, rail, sea, etc.), the quantity of steel billets being transported, and the current market conditions. On a general basis, the cost of transporting steel billets can range from $50 to $150 per metric ton. This cost typically includes the expenses related to loading and unloading the billets, transportation fees, insurance, and any additional charges such as customs fees or tolls. It is important to note that the cost can significantly differ for different modes of transportation. For example, transporting steel billets by road is generally more expensive compared to rail or sea transport due to higher fuel costs and limited capacity. Similarly, longer distances or remote locations may incur higher transportation costs due to increased logistics and infrastructure requirements. Moreover, market conditions and fluctuations in fuel prices can also impact the average cost. During periods of high demand or economic volatility, transportation costs may increase due to factors such as increased competition, fuel surcharges, or additional security measures. To get an accurate estimate for the average cost of transporting steel billets, it is recommended to obtain quotes from multiple transportation providers or consult industry-specific sources for up-to-date pricing information.

- Q: What are the main factors affecting the fatigue strength of stainless steel billets?

- The main factors affecting the fatigue strength of stainless steel billets include the composition and microstructure of the steel, the presence of surface defects or imperfections, the level of applied stress or load, the presence of corrosive environments, and the temperature at which the billets are operating.

- Q: What are the common surface defects in steel billets during cooling?

- There are several surface defects that can occur during the cooling process of steel billets. These defects can be caused by factors such as improper handling, inadequate cooling techniques, or impurities in the material. Some of the most common surface defects observed in steel billets during cooling are as follows: 1. Scale Formation: When the steel is exposed to air during the cooling process, a thin layer of oxides called scale forms on its surface. This can result in a rough and uneven surface, which diminishes the overall quality of the billet. 2. Cracks: Thermal stresses induced in the steel during cooling can lead to the formation of cracks. These cracks can be longitudinal, transverse, or even intergranular, and they compromise the structural integrity of the billet. 3. Lamination: Insufficient bonding during the cooling process can cause layers or sheets of steel to separate, resulting in lamination defects. This weakens the billet and reduces its overall strength. 4. Shrinkage Cavities: As the steel solidifies and contracts during cooling, voids or cavities called shrinkage cavities can form on the surface of the billet. These cavities weaken the steel and affect its mechanical properties. 5. Surface Roughness: Inadequate cooling techniques can cause uneven cooling and rapid solidification, ultimately leading to a rough and uneven surface texture on the billet. This defect affects the surface finish of the billet and subsequent processing. 6. Decarburization: Exposure to high temperatures and oxygen during the cooling process can cause the surface of the billet to lose carbon content, resulting in decarburization. This reduces the hardness and strength of the affected areas. To minimize these surface defects, it is crucial to implement proper cooling techniques, including controlled cooling rates, the use of protective coatings, and appropriate handling practices. Regular inspection and quality control measures are also essential to identify and rectify any defects during the cooling process, ensuring the production of high-quality steel billets.

- Q: How are steel billets used in the manufacturing of automotive parts?

- Steel billets are an essential raw material used in the manufacturing of automotive parts. These billets, which are typically short, solid pieces of steel, serve as the starting point for various automotive components. Firstly, steel billets are heated and then passed through a series of rolling mills to convert them into different shapes and sizes. This process, known as hot rolling, allows the steel billets to be transformed into bars, rods, or sheets that can be further machined or formed into automotive parts. The automotive industry relies heavily on steel billets to produce a wide range of components, such as engine blocks, crankshafts, suspension parts, and chassis frames. These parts require high strength and durability to withstand the demanding conditions of vehicles. Engine blocks, for example, are typically made from cast iron or aluminum alloys produced from steel billets. The billets are melted and poured into molds to create the desired shape, which forms the foundation of the engine. Similarly, crankshafts, which transfer power from the engine to the wheels, are often forged from steel billets to ensure strength and precision. Suspension parts, such as control arms and torsion bars, also rely on steel billets for their manufacturing. These parts need to withstand the forces and impact of the road, and steel provides the necessary strength and resilience. Billets are machined and shaped to create the required geometry and then assembled with other components to form the suspension system. Additionally, steel billets are used in the production of chassis frames, which provide the structural integrity and support for the entire vehicle. These frames are typically made from steel tubes or sections formed from billets. The billets are shaped, welded, and joined together to create a strong and rigid framework that gives stability and ensures safety. In conclusion, steel billets play a crucial role in the manufacturing of automotive parts. With their versatility and strength, they are transformed into various components that form the backbone of vehicles, ensuring durability, performance, and safety on the road.

- Q: What is the role of steel billets in the construction of airports and terminals?

- Steel billets are essential in the construction of airports and terminals due to their advantageous properties. Essentially, they are semi-finished metal products used as raw materials for manufacturing various steel products. When it comes to airports and terminals, steel billets are mainly used to produce structural steel components like beams, columns, and trusses. The strength and durability of steel billets make them preferred in the construction industry. Steel is well-known for its high tensile strength, enabling it to withstand heavy loads and structural stresses. This makes it ideal for building large and complex structures such as airports and terminals, where safety and reliability are paramount. Moreover, steel billets can be easily shaped and sized to construct different components needed in airports and terminals. These billets are often hot rolled or forged into the desired shapes, ensuring the resulting steel products have the necessary strength and structural integrity. Another advantage of using steel billets in airport and terminal construction is their resistance to adverse environmental conditions. Airports and terminals face harsh weather conditions, including extreme temperatures, moisture, and corrosion. Steel, especially when properly coated or treated, is highly resistant to these factors, ensuring the longevity and structural stability of the facilities. Furthermore, steel billets are relatively cost-effective compared to other construction materials, especially considering their durability and low maintenance requirements. The long lifespan of steel structures reduces the need for frequent repairs or replacements, resulting in cost savings over time. In conclusion, steel billets are crucial in constructing airports and terminals as they provide the required strength, durability, and versatility for large-scale structures. Their ability to withstand heavy loads, resistance to environmental factors, and cost-effectiveness make them an ideal choice for these high-demand facilities.

- Q: How are steel billets used in the manufacturing of agricultural machinery?

- Steel billets are an essential component in the manufacturing of agricultural machinery. These billets, which are semi-finished steel products, serve as the raw material for various parts and components used in agricultural machinery. One of the primary uses of steel billets in the manufacturing process is for forging and casting. Forging involves heating the billets to a high temperature and then shaping them using mechanical pressure, while casting involves pouring molten metal into a mold. Both processes allow for the creation of complex and durable components that are necessary for agricultural machinery. Steel billets are used to manufacture a wide range of agricultural machinery parts, such as engine components, transmission gears, axles, and hydraulic cylinders. These parts require excellent strength, durability, and resistance to wear, which steel billets provide. Additionally, steel's high tensile strength ensures that the machinery can withstand the demanding conditions of agricultural operations. Moreover, steel billets are used for manufacturing the frames and chassis of agricultural machinery. The frames need to be robust to support the weight and withstand the stress and vibrations generated during operation. Steel billets allow for the creation of sturdy and rigid frames that ensure the longevity and structural integrity of the machinery. Furthermore, steel billets are utilized in the production of cutting and harvesting tools, such as blades, discs, and plowshares. The exceptional hardness and sharpness of steel make it an ideal material for these tools, enabling efficient and precise agricultural operations. In summary, steel billets play a crucial role in the manufacturing of agricultural machinery. Their versatility, strength, and durability make them a suitable material for various components and parts, ensuring that the machinery can withstand the demanding conditions of agricultural operations and perform efficiently.

- Q: Are steel billets prone to cracking during production?

- Yes, steel billets are prone to cracking during production. Due to the high temperatures and rapid cooling involved in the production process, internal stresses can develop in the billets, leading to cracks. Proper handling, heat treatment, and quality control measures can help minimize the risk of cracking.

- Q: What are the common defects in billet? What's the cause?

- Three, radiographic inspection, surface defects; 3, 2, other defects, not welded and welded, undercut;Three, cold crack and fluorescence test;Four common welding defects are: 1; 4; 2:A;

- Q: How is a steel billet made?

- A steel billet is made through a process called continuous casting. It involves pouring molten steel into a water-cooled mold, which solidifies the steel into a rectangular shape. The solidified steel is then cut to the desired length to form a steel billet.

Send your message to us

Steel billets Q215 chrome alloy low price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 14950 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords