Steel Billet For Sale Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Chinese Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Billet For Sale Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Chinese Supplier

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

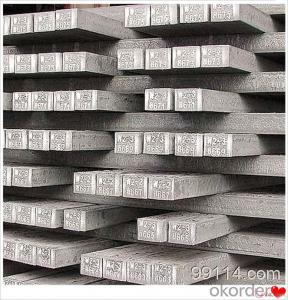

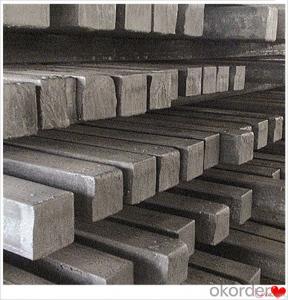

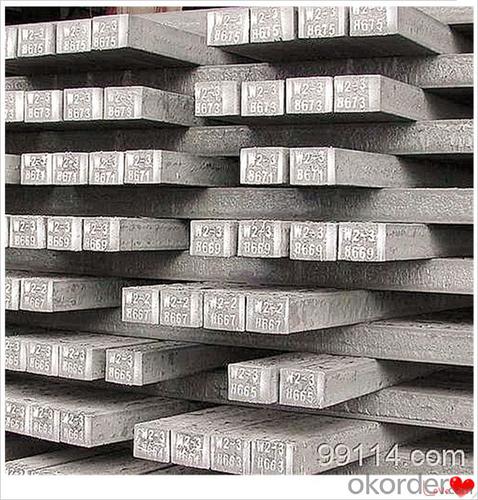

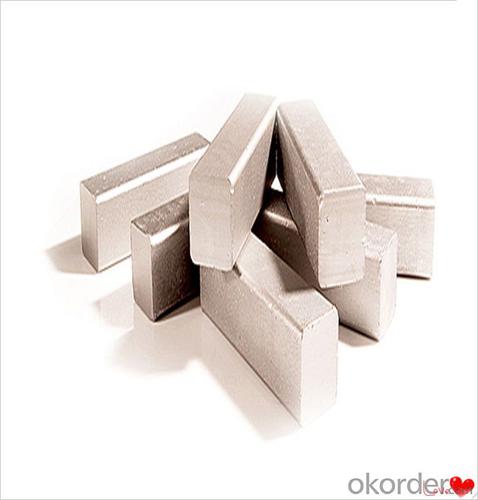

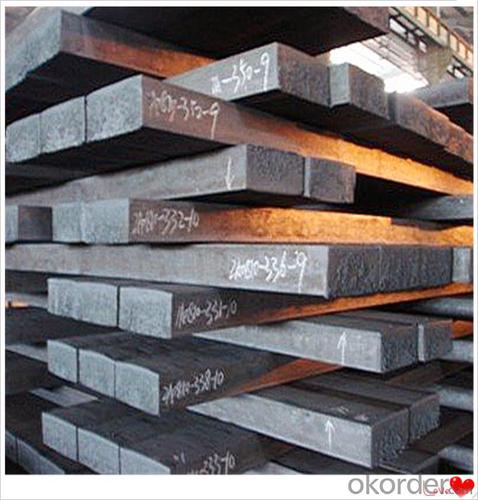

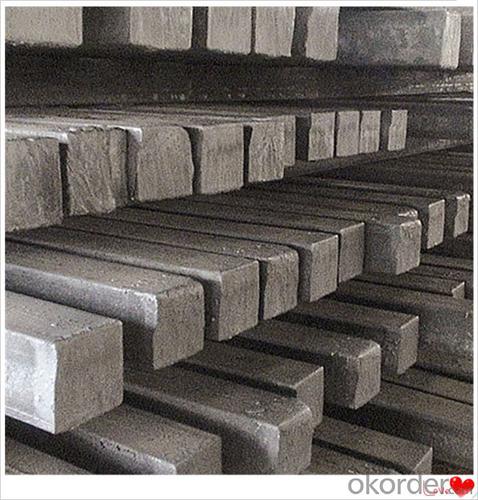

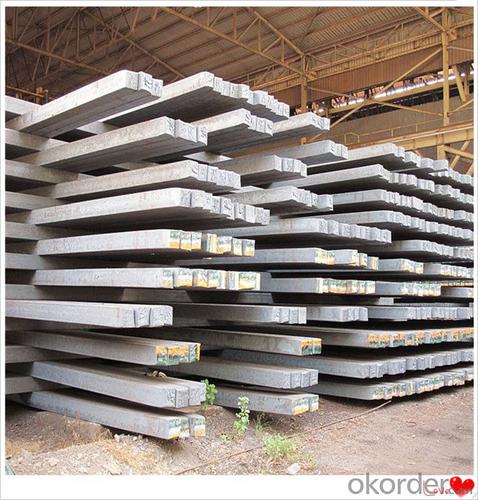

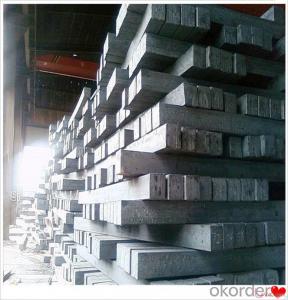

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: How are steel billets used in the manufacturing of valves and fittings?

- Valves and fittings rely on steel billets, an essential raw material, for their production. These billets are solid steel forms, cast into specific shapes and sizes. The manufacturing process starts by heating the steel billets to a high temperature and passing them through rolling mills to achieve the desired form. This process refines the grain structure, enhancing the steel's strength, ductility, and overall quality. After shaping, the billets undergo further processing and machining to create various valve and fitting components, including bodies, bonnets, stems, and other essential parts. Precise machining ensures accurate dimensions and smooth surfaces, enabling proper assembly and functioning. Steel billets also provide crucial strength and durability to valves and fittings, as they are made from high-quality steel. This ensures that the final products can withstand the harsh operating conditions, pressure, and temperature variations they may encounter. Moreover, steel billets offer versatility in manufacturing, allowing the production of different types of valves and fittings, such as gate valves, ball valves, butterfly valves, and pipe fittings. This flexibility enables manufacturers to meet diverse industry requirements. In summary, steel billets serve as the primary raw material in the production of valves and fittings. Shaping, processing, and machining these billets result in high-quality components that offer strength, durability, and precision in the final products.

- Q: What are the main types of steel billet rolling mills?

- Various types of steel billet rolling mills exist, each possessing unique characteristics and functionalities to cater to the diverse requirements of different industries. 1. Two-high rolling mills: These mills comprise two horizontally mounted rolls rotating in opposite directions. Two-high mills are commonly utilized for shaping and reducing the thickness of steel billets. They boast a relatively simple design and are suitable for light to medium-duty applications. 2. Three-high rolling mills: Three-high mills consist of three rolls arranged vertically in a triangular configuration. The upper and lower rolls are driven, while the middle roll remains idle and adjustable. This design allows for greater flexibility in shaping and reducing the dimensions of the billet. Three-high mills are often employed to produce high-quality finished products with precise dimensions and surface finishes. 3. Four-high rolling mills: Four-high mills possess four rolls, including two small diameter work rolls and two larger diameter backup rolls. The work rolls are driven, while the backup rolls provide support and adjust the billet's thickness. Four-high mills are highly versatile and can be utilized for a wide range of applications, encompassing both hot and cold rolling processes. 4. Cluster mills: Cluster mills consist of multiple small-diameter rolls arranged in a cluster. These rolls collaborate to reduce the billet's thickness and shape it into the desired form. Cluster mills are commonly utilized to produce high-precision products such as wires and thin strips. 5. Steckel mills: Steckel mills are specialized rolling mills designed for the production of heavy-gauge plates and strips. They incorporate a combination of a reversible rolling mill and a continuous casting machine. Steckel mills are renowned for their high productivity and the capability to manufacture a wide array of steel products with excellent surface quality. Each type of steel billet rolling mill boasts specific advantages and is suitable for particular applications. The selection of a mill depends on factors including the desired final product, required dimensions, production volume, and budgetary limitations.

- Q: What are the main challenges in the quality control of steel billets?

- Several factors can affect the quality and performance of steel billets, posing significant challenges in their quality control. Here, we outline some key obstacles in this regard: 1. Chemical Composition: The accurate chemical composition of steel billets is pivotal in determining their strength, durability, and mechanical properties. However, ensuring consistent chemical composition is challenging due to variations in raw materials, melting processes, and the presence of impurities. 2. Homogeneity: It is crucial to achieve uniformity in the microstructure and composition throughout the steel billet. Inadequate mixing or non-uniform cooling can lead to inconsistencies, resulting in weak areas and uneven mechanical properties. 3. Defect Detection: Detecting and eliminating defects in steel billets is essential to prevent failures during subsequent processing and usage. Common defects include cracks, inclusions, segregation, porosity, and surface irregularities. However, accurately and promptly detecting these defects can be challenging due to their size, complexity, and location. 4. Dimensional Accuracy: Consistency in the dimensions and shape of steel billets is vital for their further processing and use in various applications. Maintaining precise dimensions requires controlling variables such as casting speed, cooling rates, and mold design. 5. Surface Quality: The condition of the surface of steel billets is critical for subsequent operations like rolling, forging, or machining. Ensuring a smooth, clean, and defect-free surface is challenging due to factors such as scale formation, oxidation, decarburization, and surface contamination during handling and storage. 6. Heat Treatment: Proper heat treatment is often necessary to achieve the desired mechanical properties in steel billets. However, controlling the heating and cooling rates, as well as the soaking times, can be challenging due to variations in equipment, temperature monitoring, and quenching techniques. 7. Traceability: Maintaining traceability and documentation throughout the production process is crucial for quality control. Tracking the origin of raw materials, process parameters, testing records, and certifications can be challenging, especially in complex supply chains. To address these challenges in the quality control of steel billets, a combination of advanced testing techniques, robust process controls, skilled personnel, and continuous improvement initiatives is necessary.

- Q: Can steel billets be recycled?

- Yes, steel billets can be recycled. Steel is a highly recyclable material, and the recycling process for steel billets is relatively straightforward. When steel billets, which are typically produced through a casting process, are no longer needed or have reached the end of their lifecycle, they can be recycled and transformed into new steel products. The recycling process begins with the collection and sorting of the steel billets. They are then transported to a recycling facility where they are melted down in a furnace. Once melted, impurities are removed, and the resulting molten steel is formed into new billets or other steel products through various shaping and casting techniques. Recycling steel billets not only helps to conserve natural resources and reduce waste but also has significant environmental benefits. The recycling process requires less energy and emits fewer greenhouse gases compared to the production of steel from raw materials. Additionally, recycling steel helps to reduce the demand for mining iron ore, which can have detrimental effects on the environment. Overall, steel billets can be effectively recycled, allowing for the sustainable and responsible use of this versatile material.

- Q: Can steel billets be used in the aerospace industry?

- Indeed, the aerospace industry does make use of steel billets. These billets, classified as semi-finished products, can undergo further processing to create the diverse components and structures necessary for aerospace purposes. The strength, durability, and heat resistance of steel are well-known attributes that prove vital in aerospace materials. By employing steel billets, one can fabricate a range of aerospace components, including engine parts, landing gear, structural frames, and fasteners. Furthermore, steel's availability and cost-effectiveness enhance its appeal for specific aerospace applications. Nonetheless, it is imperative to acknowledge that adhering to the aerospace industry's specific requirements and standards is crucial when employing steel billets, ensuring the utmost levels of safety and reliability.

- Q: How are steel billets used in the production of railway tracks?

- Steel billets are the raw materials used in the production of railway tracks. They are heated, shaped, and rolled to form long, flat bars known as rails. These rails are then laid on the trackbed, forming the foundation for the tracks on which trains run.

- Q: What are the potential applications of steel billets in the mining industry?

- Steel billets have various potential applications in the mining industry. They can be used as raw material for the production of mining equipment, such as drill bits, shovels, and conveyor systems. Additionally, steel billets can be used in the construction of mine infrastructure, including support structures, platforms, and walkways. Their high strength and durability make them suitable for heavy-duty applications within the mining sector.

- Q: What is the average lead time for ordering steel billets?

- The lead time for ordering steel billets can vary depending on several factors, including the supplier, quantity needed, production capacity, and current market conditions. Typically, the lead time can range from a few weeks to a couple of months. If the supplier has readily available stock or a short production cycle, the lead time may be shorter, usually around two to four weeks. However, if the supplier needs to produce the steel billets specifically for the order, it may take longer. In such cases, the lead time can extend to six to eight weeks or even longer, particularly if there are any production process delays. Considering the quantity required is also crucial. Smaller orders may have shorter lead times compared to larger quantities, as they can be accommodated within the supplier's existing production schedule or available stock. Furthermore, market conditions play a significant role. When there is high demand or disruptions in the supply chain, lead times may increase due to heightened competition for resources and longer production cycles. To obtain an accurate estimate of the average lead time for ordering steel billets, it is advisable to contact multiple suppliers and discuss your specific requirements with them. They can provide more precise information based on their production capabilities and the current market conditions.

- Q: Reasons and treatment methods of billet stripping in continuous casting

- even two cold regions can be uniformly cooled, due to uneven thickness of shell, caused by the inconsistent temperature, the shell shrinkage is still uneven, and also there will be the development of. Therefore, the selection of unqualified mold is the main reason causing the removal. Secondly, the cooling effect of the two cooling zone can not be ignored.

- Q: How do steel billets contribute to the overall safety of a structure?

- Steel billets play a significant role in contributing to the overall safety of a structure in several ways. Firstly, steel billets serve as the raw material for manufacturing steel bars, beams, columns, and other structural components. These components are widely used in construction due to their high strength and durability. By using steel billets as the starting material, the resulting steel products exhibit excellent load-bearing capacity, which enhances the structural integrity of the building. Moreover, steel billets undergo a rigorous manufacturing process that includes various quality control checks. These checks ensure that the billets possess consistent and reliable mechanical properties, such as high tensile strength and impact resistance. As a result, when these billets are used in the construction of a structure, they contribute to its overall safety by providing a reliable and robust framework that can withstand external forces, such as wind, earthquakes, or heavy loads. Additionally, steel billets are often produced using advanced metallurgical techniques, such as controlled cooling or heat treatment, to achieve specific properties required for structural applications. These processes help in improving the microstructure of the steel, reducing internal defects, and enhancing its resistance to corrosion, fatigue, and other forms of degradation. This, in turn, increases the lifespan of the structure and minimizes the risk of structural failure, thus ensuring the safety of the occupants. Furthermore, steel billets can be manufactured with precise dimensions and tolerances, allowing for accurate and efficient construction. This precision in fabrication ensures that structural components fit together seamlessly, reducing the likelihood of gaps, misalignments, or weak points that could compromise the safety of the structure. Lastly, steel billets are highly recyclable, making them an environmentally friendly choice for construction. By opting for steel billets, the construction industry can reduce its carbon footprint and contribute to sustainable development. This focus on sustainability aligns with the overall safety of a structure, as a sustainable approach ensures the long-term stability and resilience of the built environment. In conclusion, steel billets contribute to the overall safety of a structure by providing high-strength, durable, and reliable materials for construction. Their consistent mechanical properties, resistance to external forces, improved microstructure, and precise fabrication ensure a strong and secure framework. Moreover, their recyclability promotes sustainability, further enhancing the long-term safety and integrity of the structure.

Send your message to us

Steel Billet For Sale Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Chinese Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords