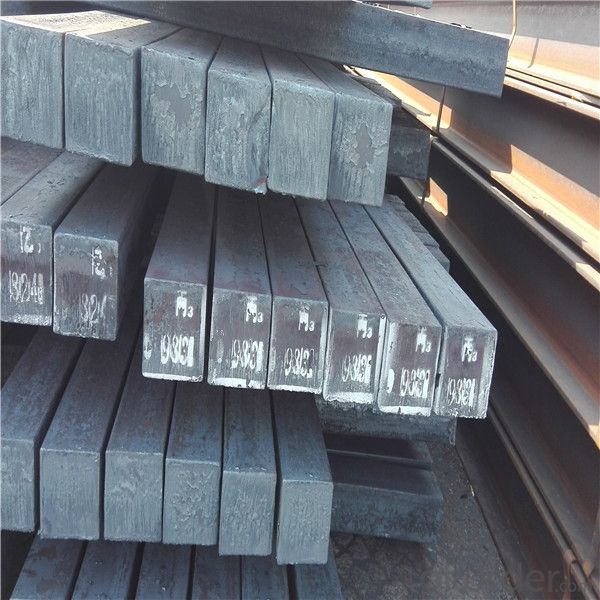

Q235 Q275 square steel billet for sale low price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16800 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet

(ingot) by cogging or breakdown of semifinished products, is the raw material of all kinds of steel mill.

Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the

shape of rolled products.

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Size :100mm to 165mm

Length:6~12meters

Grade: Q195/Q215/Q235/Q275

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Payment terms: 100%Irrevercable L/C at sight or T/T

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the main factors affecting the cost of steel billets?

- The main factors affecting the cost of steel billets include the price of raw materials such as iron ore and coal, global supply and demand dynamics, production and transportation costs, energy prices, currency exchange rates, and market speculation. Additionally, factors like trade policies, government regulations, and geopolitical events can also impact the cost of steel billets.

- Q: How is the quality of steel billets ensured during production?

- The quality of steel billets is ensured during production through various measures such as regular testing and inspection. This includes conducting chemical analysis to ensure the correct composition, as well as mechanical testing to check the strength and durability of the billets. Additionally, visual inspections are carried out to identify any surface defects or imperfections. Strict quality control measures are implemented at every stage of the production process to ensure that the steel billets meet the required standards and specifications.

- Q: How are steel billets used in the production of construction parts?

- Steel billets are used in the production of construction parts as they serve as the raw material for various manufacturing processes. These billets are heated and then shaped into different forms such as beams, columns, and rods through processes like rolling and forging. The resulting construction parts are strong, durable, and capable of withstanding the structural demands of buildings and infrastructure projects.

- Q: How do steel billets contribute to the overall corrosion protection of a structure?

- Steel billets, classified as semi-finished steel products, play a crucial role in safeguarding structures against corrosion. They contribute to corrosion protection through multiple means: 1. Superior steel composition: Steel billets are crafted from top-notch steel that comprises different alloying elements, like chromium, nickel, and molybdenum. These elements amplify the steel's resistance to rust and corrosion, making it less vulnerable. 2. Protective layering: Steel billets are often coated with protective layers, such as zinc or epoxy coatings. These coatings function as a barrier between the steel surface and the external environment, obstructing moisture, oxygen, and other corrosive substances from reaching the steel and causing corrosion. 3. Enduring strength: Steel billets are renowned for their remarkable strength and durability. When utilized in construction, they provide a robust foundation and structural support. This strength and durability minimize the likelihood of structural damage and corrosion, guaranteeing the stability and longevity of the structure. 4. Welding capability: Steel billets possess exceptional weldability, facilitating easy and efficient joining of steel components during construction. Proper welding techniques and materials can further augment the structure's corrosion resistance by preserving the integrity and continuity of the protective coatings. 5. Maintenance and repair: In the event of damage or corrosion on the structure, steel billets can be readily replaced or repaired. This ensures that the affected area can be rectified without compromising the overall integrity and corrosion protection of the structure. Regular maintenance and repair of steel billets contribute to the long-term corrosion protection of the entire structure. In conclusion, steel billets contribute significantly to the overall corrosion protection of structures through their high-quality composition, protective coatings, durability, weldability, and ease of maintenance and repair. By incorporating steel billets into construction projects, engineers and architects can ensure the longevity, safety, and corrosion resistance of structures in diverse environments.

- Q: How do steel billets contribute to the fire resistance of a structure?

- Steel billets primarily contribute to the fire resistance of a structure by providing structural stability and integrity during a fire. The high melting point of steel, combined with its strength and durability, allows it to withstand extreme temperatures for a longer period of time compared to other building materials. This helps to slow down the spread of fire and prevents structural collapse, giving occupants more time to evacuate and firefighters more time to control the blaze.

- Q: How are steel billets used in the production of reinforcing bars?

- The production of reinforcing bars relies heavily on steel billets, a crucial element in the process. These billets, categorized as semi-finished steel products, act as the primary raw material. To facilitate the formation of reinforcing bars, the steel billets undergo heating within a furnace, reaching a specific temperature. This heating procedure serves to enhance the steel's malleability, making it more pliable and easier to mold. Once the desired temperature is achieved, the billets progress through a sequence of rolling mills. These mills exert substantial pressure on the billets, progressively reducing their size and shaping them into the necessary dimensions for reinforcing bars. Additionally, the rolling process enhances the steel's mechanical properties, augmenting its strength and durability. After the completion of the rolling process, the elongated steel bars are cut into precise lengths based on desired dimensions and requirements. Subsequently, these lengths are allowed to cool, promoting steel stabilization and averting any deformations. Ultimately, the reinforcing bars undergo a surface treatment process, such as hot-dip galvanization or epoxy coating. This treatment imparts corrosion resistance and extends the lifespan of the reinforcing bars. Consequently, the performance and durability of these bars are enhanced, rendering them suitable for utilization in construction projects. In conclusion, steel billets are indispensable in the initial phases of reinforcing bar production. By means of heating, rolling, cutting, and surface treatment processes, these billets are transformed into high-strength steel bars that reinforce concrete structures.

- Q: What is the role of steel billets in the construction of sports facilities?

- Steel billets play a crucial role in the construction of sports facilities. These billets, which are essentially semi-finished steel products, are used as the primary raw material for manufacturing various structural components and equipment necessary for sports complexes. One of the key applications of steel billets in sports facility construction is in the production of steel beams and columns. These structural elements provide the necessary support and stability to the buildings, ensuring safety for athletes and spectators. Steel billets are melted and shaped into these beams and columns, which are then used to create the framework of the sports facility. Additionally, steel billets are also utilized in the fabrication of sports equipment such as goalposts, fencing, and handrails. These components require high strength and durability to withstand the physical demands of the sport and the wear and tear from extensive use. By using steel billets, these equipment can be manufactured to meet the required strength standards while also ensuring longevity and safety. Moreover, steel billets are used in the construction of seating areas and grandstands within sports facilities. The high load-bearing capacity and structural integrity of steel make it an ideal material for supporting large crowds. By using steel billets, these seating areas can be constructed to withstand heavy loads and provide a safe and comfortable environment for spectators. Furthermore, steel billets are also instrumental in the construction of roofing and façade systems. Steel panels made from these billets offer excellent resistance to weathering, corrosion, and fire, making them suitable for outdoor sports facilities. These panels can be fabricated to provide the necessary insulation, protection, and aesthetic appeal, enhancing the overall functionality and appearance of the sports complex. In conclusion, steel billets have a vital role in the construction of sports facilities. From manufacturing structural elements to producing sports equipment and creating seating and roofing systems, steel billets provide the necessary strength, durability, and safety required for such facilities. Their versatility and reliability make them an indispensable component in the construction process, ensuring that sports complexes are built to meet the highest standards of quality and performance.

- Q: What are the different types of cutting machines used for steel billets?

- There are several different types of cutting machines used for steel billets, including bandsaws, circular saws, plasma cutters, and waterjet cutters. Each type of machine has its own advantages and disadvantages depending on factors such as the required precision, cutting speed, and material thickness.

- Q: What are the different types of steel billet surface treatment defects?

- During the manufacturing process, various defects can arise in the surface treatment of steel billets. The presence of these defects can have a negative impact on the quality and appearance of the billets, making it essential to detect and resolve them in order to guarantee the overall performance of the end product. 1. One common defect is scale, which occurs when the steel billet is exposed to high temperatures. This results in the formation of an oxide layer on the surface, adversely affecting the adhesion of coatings or paints. 2. Inclusions are another type of defect that can be found on the surface of the steel billet. These inclusions are non-metallic particles or impurities that may originate from inadequate cleaning or improper handling during the manufacturing process. They have the potential to undermine the mechanical properties of the steel, leading to an overall reduction in performance. 3. Decarburization is a defect that arises when the carbon content in the outer layer of the steel billet is lost due to exposure to high temperatures or a lack of protective atmosphere. This loss of carbon can result in decreased hardness and strength in the affected area. 4. Pitting is a localized defect characterized by the presence of small cavities or pits on the surface of the steel billet. It can be caused by impurities or exposure to corrosive environments. Pitting has the potential to compromise the structural integrity of the billet and make it more susceptible to corrosion. 5. Surface cracks may occur on the steel billet due to factors such as thermal stress, improper handling, or inadequate cooling. These cracks weaken the billet and increase the risk of failure during subsequent processing or use. 6. Surface roughness refers to an uneven or irregular texture on the surface of the steel billet. It can be caused by factors such as improper machining, inadequate cleaning, or the presence of scale or inclusions. Surface roughness affects the appearance of the billet and can impact its performance in certain applications. In conclusion, it is crucial to identify and resolve these surface treatment defects to ensure the quality and reliability of steel billets. Employing proper manufacturing processes, including thorough cleaning, protective atmospheres, and appropriate handling, is key to minimizing the occurrence of these defects and ensuring optimal performance of the final product.

- Q: What are the international standards or certifications for steel billets?

- The international standards or certifications for steel billets include ASTM A615/A615M-20, ASTM A706/A706M-16, BS 4449:2005+A3:2016, and EN 10025-2:2004. These standards provide specifications for the chemical composition, mechanical properties, and dimensions of steel billets, ensuring their quality and suitability for various applications in the construction industry.

Send your message to us

Q235 Q275 square steel billet for sale low price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16800 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords