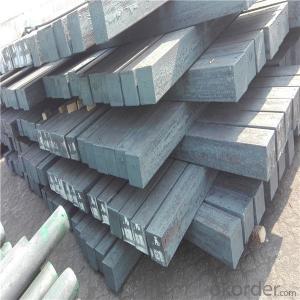

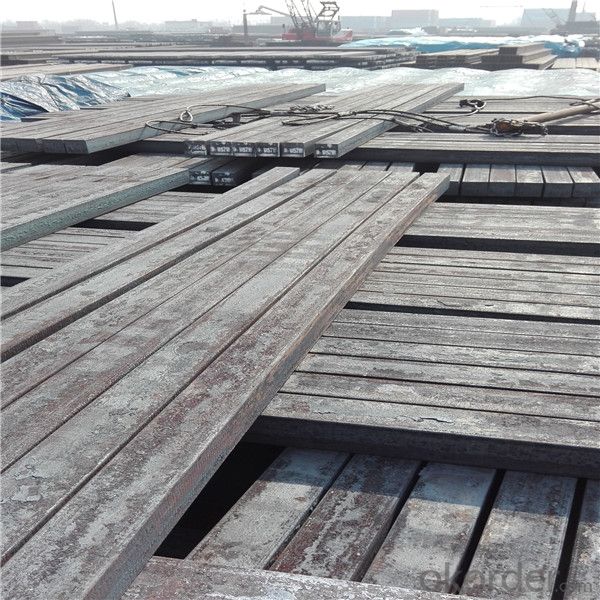

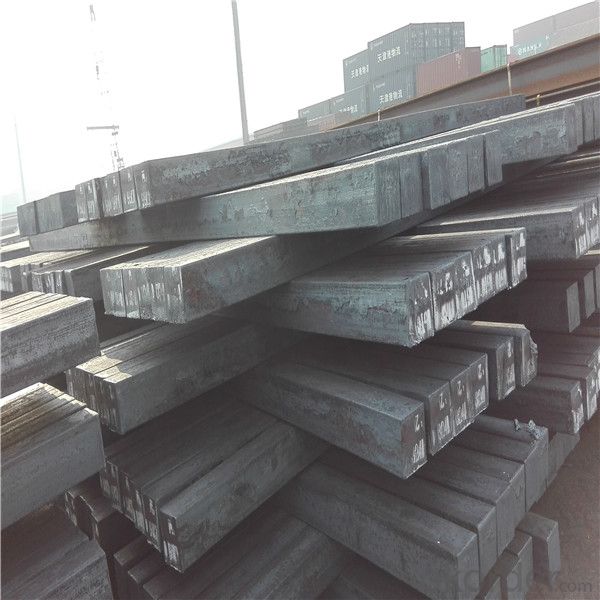

Steel billets Q215 grade hot sale factory price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

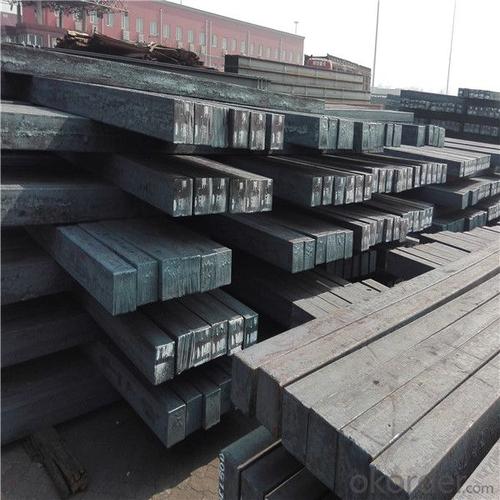

Steel billets have distinct characteristics as compared with already furnished steel bars and products.

Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets

are also known for their malleability and ductility, especially when exposed to varying temperatures during

shaping and molding.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building

the support foundation pile manufacturing.

Size :100mm to 165mm

Length:6~12meters

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Payment terms: 100%Irrevercable L/C at sight or T/T

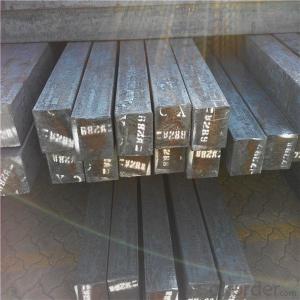

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the challenges faced in the production of steel billets?

- There are several challenges faced in the production of steel billets. Some of the major challenges include ensuring consistent quality and composition of the billets, managing the high temperatures involved in the production process, minimizing energy consumption, and meeting environmental regulations. Additionally, maintaining the proper size and shape of the billets throughout the production process is crucial, as any deviations can lead to subsequent processing issues. Overall, the production of steel billets requires careful monitoring, control, and adherence to strict standards to overcome these challenges.

- Q: What is the typical tensile strength of a steel billet?

- The typical tensile strength of a steel billet can vary depending on the specific grade and composition of the steel. However, in general, steel billets have a tensile strength ranging from 370 to 550 megapascals (MPa). This range is commonly found in low to medium carbon steels used for various applications in industries such as construction, automotive, and manufacturing. It is important to note that higher-grade steels, such as alloy steels, can have significantly higher tensile strengths, exceeding 1000 MPa. Ultimately, the tensile strength of a steel billet is determined by its intended application and the specific requirements of the project.

- Q: Are steel billets used in the production of household appliances?

- Yes, steel billets are used in the production of household appliances. Steel billets are semi-finished steel products that are used as raw material in various industries, including the manufacturing of household appliances. These billets are heated and then rolled or forged into different shapes and sizes to create components such as sheets, plates, rods, and bars that are used in the production of appliances. Steel is a preferred choice for household appliances due to its strength, durability, and resistance to corrosion. It is commonly used in the production of refrigerators, washing machines, dishwashers, ovens, and many other household appliances.

- Q: What are the different types of steel billet rolling mill automation systems?

- There are several different types of steel billet rolling mill automation systems that are commonly used in the industry. These systems are designed to improve the efficiency, accuracy, and overall productivity of the rolling mill operations. Here are some of the most commonly used automation systems: 1. Level 1 Automation: This is the basic level of automation that includes basic control and monitoring functions. It typically involves the use of programmable logic controllers (PLCs) to control and monitor various aspects of the rolling mill, such as speed, temperature, and pressure. This level of automation provides basic functionality but may require manual intervention for certain tasks. 2. Level 2 Automation: This level of automation goes beyond the basic control and monitoring functions of level 1. It includes advanced process control algorithms and models to optimize the rolling mill operations. Level 2 automation systems can automatically adjust the mill parameters, such as roll gap, roll speed, and cooling water flow, to achieve the desired product specifications. These systems also provide real-time process monitoring and data analysis capabilities. 3. Level 3 Automation: This level of automation focuses on the integration of the rolling mill with other systems in the plant, such as the material handling system and the quality control system. It includes features like automatic scheduling, inventory management, and seamless data exchange between different systems. Level 3 automation systems enable better coordination and synchronization of the entire production process, resulting in improved efficiency and reduced downtime. 4. Artificial Intelligence (AI) and Machine Learning: Some advanced automation systems leverage AI and machine learning algorithms to continuously learn from the data collected during the rolling mill operations. These systems can predict equipment failures, optimize production parameters, and even suggest process improvements. AI and machine learning-based automation systems enable proactive maintenance, better decision-making, and increased overall productivity. 5. Robotics and Robotics-assisted Automation: In some steel billet rolling mills, robots are used for various tasks, such as loading and unloading, quality inspection, and maintenance. Robotic automation systems offer precision, speed, and repeatability, reducing the need for manual labor and improving safety. These systems can be integrated with other automation systems to create a fully automated and efficient rolling mill operation. Overall, the different types of steel billet rolling mill automation systems offer varying levels of functionality and sophistication. The choice of automation system depends on the specific requirements of the mill, the desired level of automation, and the available budget.

- Q: What are the main factors affecting the hardenability of alloy steel billets?

- The main factors affecting the hardenability of alloy steel billets include the chemical composition of the alloy, the grain size and distribution, the cooling rate during heat treatment, and the presence of alloying elements such as carbon, manganese, chromium, and molybdenum. These factors determine the ability of the steel to form and retain a hardened structure, thus affecting its overall hardness and strength properties.

- Q: How do steel billets contribute to the manufacturing of electrical appliances?

- Steel billets are used in the manufacturing of electrical appliances as they serve as a raw material for various components. These billets are transformed into sheets, wires, or rods which are then used to create the outer casings, frames, or conductive elements of the appliances. The strength and durability of steel make it an ideal choice for ensuring the longevity and safety of electrical appliances.

- Q: How are steel billets used in the production of turbine blades?

- Steel billets are used in the production of turbine blades as raw material. These billets are first forged into the desired shape and then undergo precision machining to achieve the required dimensions and finish. The steel billets provide the strength and durability necessary to withstand the high temperatures and forces experienced by turbine blades during operation.

- Q: How are steel billets inspected before they are used in production?

- Steel billets are inspected thoroughly before they are used in production to ensure their quality and adherence to the required specifications. The inspection process typically involves several key steps. Firstly, visual inspection is conducted to examine the surface of the billets for any surface defects such as cracks, seams, or deformities. Any irregularities can indicate potential weaknesses or problems in the billet that may affect its performance during production. Secondly, dimensional inspection is performed to verify the billet's size, length, width, and other critical dimensions. This is crucial to ensure that the billets meet the precise requirements of the production process and can be seamlessly integrated into the manufacturing operations. Thirdly, ultrasonic testing is often employed to detect any internal defects or discontinuities within the billets. Ultrasonic waves are passed through the billet, and any reflections or echoes are analyzed to identify any flaws such as voids, inclusions, or cracks that may compromise the structural integrity of the billets. Additionally, magnetic particle inspection may be carried out to identify surface or near-surface defects that may not be visible to the naked eye. This technique involves applying magnetic particles to the surface of the billet and detecting any magnetic leakage caused by defects through the use of magnetic fields. Furthermore, chemical analysis is frequently performed to ensure that the steel billets have the desired chemical composition. This involves taking samples from the billets and subjecting them to various tests to determine the percentages of different elements present. This analysis guarantees that the billets possess the necessary chemical properties for the intended application. Overall, steel billets undergo a comprehensive inspection process that encompasses visual examination, dimensional verification, ultrasonic testing, magnetic particle inspection, and chemical analysis. This multi-faceted approach ensures that the billets meet the required quality standards and are suitable for use in production, thus minimizing the risk of any performance issues or failures during manufacturing processes.

- Q: What are the quality standards for steel billets?

- The quality standards for steel billets typically include criteria such as chemical composition, dimensional accuracy, surface finish, mechanical properties, and internal soundness. These standards ensure that the steel billets meet the required specifications for various applications and guarantee their strength, durability, and suitability for further processing.

- Q: Charcoal is how to

- Usually we measure the quality of charcoal mainly from the moisture content, volatile content, ash content, fixed carbon content and calorific value of charcoalTake it, thanks!!

Send your message to us

Steel billets Q215 grade hot sale factory price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords