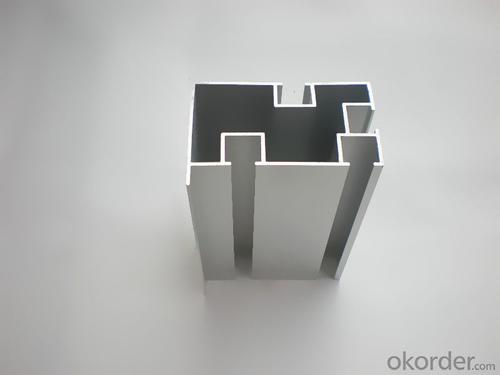

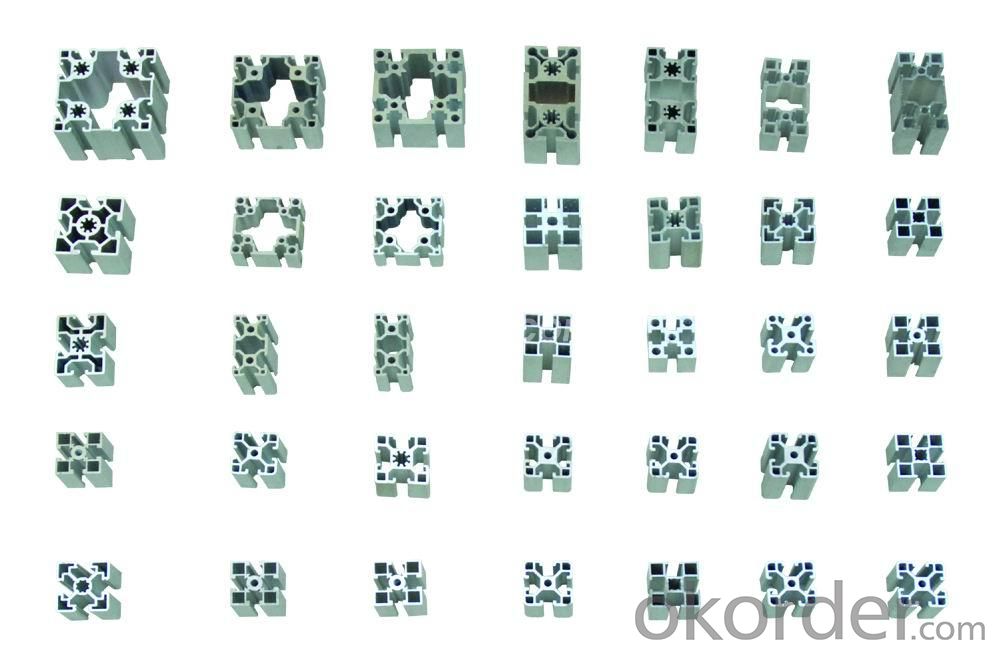

Aluminum Frame Extrusion Profiles - Alloy 6063, 6061, 6005 or Custom Choice Aluminium Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

- Q: I am a mold professional, in school are mainly plastic mold and stamping die, but I am now in an aluminum extrusion die master apprentice. Draw pictures every day and walk around the workshop. But I have never met any related knowledge before, and I don't know where to start. I don't know what to do. Sometimes even want to give up, but not reconciled. I hope you can give me some advice. Thank you very much!!!

- 1, to let them die factory processing, mold design they figure, their wages are high, so I want to learn, do not know where to start, buy a book, the mold design of aluminum extrusion, want to learn to know the properties of extrusion machine, structure;2, according to the experience, to a step by step to produce aluminum profile extrusion die to meet the size requirements, first of all to ensure the uniformity of metal flow and extrusion out of the heart often Youao phenomenon, cause the surface subsidence, the flatness is not standard, through a lot of practice conclusion.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles within the construction industry.

- <p>Aluminum profiles offer several advantages in construction, including high strength-to-weight ratio, corrosion resistance, and ease of fabrication. They are lightweight, which reduces the load on structures and facilitates easier installation. Their resistance to corrosion means they require less maintenance and have a longer lifespan compared to steel. Additionally, aluminum profiles can be easily cut, bent, and joined, making them versatile for various applications. However, they have some disadvantages, such as lower thermal conductivity, which can be a concern in temperature-sensitive environments. They are also more expensive than some traditional materials like steel. Lastly, aluminum profiles can dent or deform under heavy loads, which may limit their use in certain structural applications.</p>

- Q: Can aluminum profiles be utilized in creating distinctive architectural structures?

- <p>Yes, aluminum profiles can be used to create unique architectural designs. They are favored for their strength, lightweight, and corrosion resistance. Architects can utilize aluminum's flexibility to design complex structures, such as intricate facades, modern window systems, and innovative support frameworks. Aluminum's adaptability allows for both functional and aesthetically pleasing designs, making it a popular choice in contemporary architecture.</p>

- Q: This question asks for methods to prevent corrosion on aluminum profiles during the installation process.

- <p>To prevent corrosion of aluminum profiles during installation, follow these steps: 1. Use stainless steel fasteners and avoid galvanized or carbon steel screws which can cause galvanic corrosion. 2. Keep the aluminum profiles clean and dry during installation to avoid contact with moisture which can initiate corrosion. 3. Apply a protective coating or sealant to the profiles, especially at cut edges where the protective oxide layer may be compromised. 4. Store aluminum profiles in a dry, cool place before installation to prevent moisture absorption. 5. Regularly inspect and maintain the profiles to identify and address any signs of corrosion early. By adhering to these practices, you can significantly reduce the risk of corrosion on aluminum profiles during installation.</p>

- Q: Can aluminum profiles be used in exhibition or trade show displays?

- Exhibition or trade show displays can incorporate aluminum profiles, which are lightweight, durable, and versatile. These profiles are an excellent option for constructing exhibition displays due to their ability to be easily assembled and disassembled, enabling swift setup and dismantling at trade shows. Furthermore, aluminum profiles can be tailored to produce diverse shapes and sizes to accommodate various exhibition booth designs. They can also be effortlessly combined with other materials like fabric, glass, or acrylic panels to create visually appealing and professional displays. Ultimately, aluminum profiles present a practical and cost-effective solution for exhibition or trade show displays.

- Q: This question asks for the proper and safe method of installing aluminum profiles, which are commonly used in construction and manufacturing.

- <p>To install aluminum profiles correctly and safely, follow these steps: 1. Plan the layout and measure the required lengths accurately. 2. Use appropriate cutting tools to cut the profiles to size, ensuring a clean edge. 3. Apply protective gloves and eyewear when handling aluminum profiles to avoid injury. 4. Use the correct fasteners, such as screws or bolts, compatible with the aluminum profiles. 5. Ensure the profiles are securely fastened and aligned properly. 6. Check for any sharp edges or burrs after installation and smooth them out to prevent injury. 7. Always follow the manufacturer's guidelines and safety precautions. Proper installation and safety measures will ensure the longevity and stability of the aluminum profiles.</p>

- Q: Will the aluminum profile be deformed at about 100 degrees?

- Subject to circumstances:1, aluminum material or brand2 、 what is the forming state of aluminum profile, such as conventional: O, T4, T5, T6 and so on3. How long is it within 100 degrees of heat? Continuous or intermittent entry, such as intermittent access, interval time, etc.4, the aluminum profile forming itself has a certain mechanical strength, such as tensile and yield and ductility, etc., but these mechanical strength is based on different materials (section shape) in different extrusion processing (T) Inferior.For example, a solid bar around 10MM, material 6061-T6, a short time into the furnace temperature of 100 degrees, the annealing temperature will make its hardness drops more quickly, then a long time will decrease, but no hardness.The material you say can not be deformed, the aforementioned points need to be clear, or any answer is biased, and I hope to help you!

- Q: This question asks for guidance on selecting the appropriate size and shape of aluminum profiles for a specific application.

- <p>Choosing the right size and shape of an aluminum profile involves several steps. First, consider the load-bearing requirements and structural integrity needed for your application. Consult with engineering standards or use software that can simulate the stress and load on the profile. Second, consider the aesthetic and functional requirements, such as the profile's visibility and the need for specific features like slots or holes. Third, review the available profiles from suppliers, matching your needs with their offerings. Finally, prototype with the selected profile to ensure it meets all requirements before full-scale production. Always consult with aluminum profile manufacturers or suppliers for their expertise and recommendations.</p>

- Q: What are the different types of fasteners used for aluminum profiles?

- Some of the different types of fasteners used for aluminum profiles include screws, bolts, nuts, rivets, and T-slot nuts. These fasteners are designed to securely join aluminum profiles together for various applications in industries such as construction, manufacturing, and automotive.

- Q: Are aluminum profiles suitable for use in exterior wall insulation systems?

- <p>Yes, aluminum profiles can be used for exterior wall insulation systems. They are known for their durability, resistance to corrosion, and ability to withstand various weather conditions. Aluminum profiles provide a strong structural framework that can support insulation materials effectively. They are also lightweight, which makes them easy to handle and install. Additionally, aluminum profiles can be anodized or coated to enhance their resistance to environmental factors, making them a popular choice for exterior insulation systems.</p>

Send your message to us

Aluminum Frame Extrusion Profiles - Alloy 6063, 6061, 6005 or Custom Choice Aluminium Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords