Extruded Aluminum Profiles China - Alloy 6063, 6061, 6005 Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

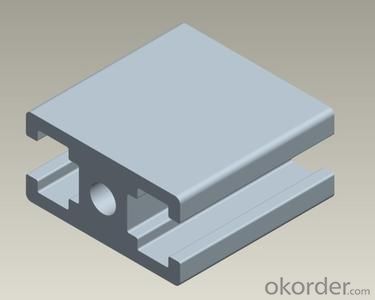

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: Are aluminum profiles suitable for electrical applications?

- Yes, aluminum profiles are suitable for electrical applications. Aluminum is a lightweight, durable, and corrosion-resistant material that can effectively dissipate heat, making it ideal for electrical components such as heat sinks, enclosures, and bus bars. Additionally, aluminum profiles can be easily customized and fabricated to meet specific electrical requirements.

- Q: Can aluminum profiles be used for DIY projects or home improvement?

- Yes, aluminum profiles can be used for DIY projects or home improvement. Aluminum profiles are versatile and can be easily customized and fabricated to fit various applications. They are lightweight, durable, and resistant to corrosion, making them suitable for a wide range of projects such as shelving, framing, furniture, and even outdoor structures like pergolas or fences. Additionally, aluminum profiles are available in different shapes and sizes, allowing for flexible and creative designs.

- Q: Can aluminum profiles be used for trade show booths?

- Indeed, trade show booths can utilize aluminum profiles. These profiles, being lightweight and durable, lend themselves well to customization, accommodating a wide range of shapes and sizes. They serve as a reliable foundation for constructing trade show booths, while also granting design flexibility, facilitating effortless assembly, disassembly, and transport. Furthermore, aluminum profiles can be seamlessly integrated with other materials like fabric, glass, or acrylic panels, creating trade show booths that are both visually captivating and practical. In summary, owing to their versatility, strength, and user-friendliness, aluminum profiles remain a favored option in the trade show industry.

- Q: Are aluminum profiles suitable for historical or heritage restoration projects?

- Yes, aluminum profiles can be suitable for historical or heritage restoration projects. Aluminum is a versatile material that offers several advantages for restoration projects. Firstly, aluminum profiles can be manufactured to replicate traditional architectural features and designs, allowing for seamless integration and preservation of the historical aesthetics. Aluminum is also a lightweight material, making it easier to handle and install, especially in complex or intricate restoration projects. Additionally, aluminum is highly durable and resistant to corrosion, which is crucial for preserving the structural integrity and longevity of historical buildings or structures. Furthermore, aluminum profiles can be easily customized and fabricated to match the specific requirements of historical restoration projects. They can be shaped, cut, and finished to replicate the original architectural elements, such as windows, doors, trim, or decorative features. Moreover, aluminum profiles offer excellent thermal performance, providing improved energy efficiency and insulation for restored buildings. This can help reduce energy consumption, lower heating or cooling costs, and enhance the overall comfort of the space. While traditional materials like wood or steel have been commonly used in historical restoration projects, aluminum profiles offer a modern alternative that combines aesthetic appeal, durability, and sustainability. However, it is important to ensure that the use of aluminum profiles aligns with the preservation guidelines and regulations of the specific historical or heritage project. In conclusion, aluminum profiles can be a suitable choice for historical or heritage restoration projects due to their versatility, durability, lightweight nature, customization options, and energy efficiency. They can successfully blend modern functionality with historical aesthetics, contributing to the preservation and revitalization of our architectural heritage.

- Q: This question asks for a list of various fastening methods used to connect aluminum profiles to the structural frames of buildings.

- <p>There are several types of fasteners used to attach aluminum profiles to building frames, including: 1) Bolts and Nuts: Commonly used for strong, secure connections. 2) Rivets: Provide a permanent connection that is resistant to vibration. 3) Self-Tapping Screws: Can be used in materials without pre-drilling. 4) Structural Glue: Offers a strong bond and is often used in combination with mechanical fasteners. 5) Welding: Used for permanent, load-bearing connections, though not common for aluminum due to the risk of thermal distortion. 6) Clamps and Brackets: Used for temporary or adjustable connections. 7) Adhesive Tapes: Provide a quick and easy method of attachment, though not as strong as other methods. Each type of fastener has its own advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: This question asks for a comparison between aluminum profiles and other materials used in constructing frames, focusing on their characteristics and performance.

- <p>Aluminum profiles are favored for building frames due to their high strength-to-weight ratio, making them lightweight yet durable. They offer excellent corrosion resistance, which is superior to materials like steel, which can rust. Aluminum profiles are also easy to machine and form, allowing for complex designs. Compared to wood, they are more resistant to weathering and pests. However, they may not have the same aesthetic appeal as wood or the thermal insulation properties of some plastics. Overall, aluminum profiles are a strong choice for structural integrity and longevity in frame construction.</p>

- Q: How do you attach accessories or components to aluminum profiles?

- Attaching accessories or components to aluminum profiles can be done in multiple ways. One commonly used technique involves the use of T-slot nuts and bolts. T-slot nuts can easily slide into the T-slot groove on the profile and can be placed at any desired location along its length. Subsequently, the bolts are utilized to firmly secure the accessory or component to the nut, establishing a sturdy and dependable connection. Another alternative is to employ brackets or mounting plates that are specifically designed for aluminum profiles. These brackets generally possess pre-drilled holes that align perfectly with the T-slot grooves, allowing for effortless attachment of accessories. They can be fastened to the profile using screws or bolts. Furthermore, there are various specialized connectors available for specific applications. Examples of these connectors include corner connectors, joining plates, and hinge connectors. These connectors offer convenient and reliable methods to attach accessories or components to aluminum profiles without the necessity of additional drilling or machining. When selecting the attachment method, it is crucial to consider the weight and load-bearing requirements of the accessories or components. Utilizing suitable fasteners and connectors guarantees a secure attachment, preventing any potential hazards.

- Q: How are the tonnage grades of aluminum extrusion machines classified?

- Aluminum Alloy stamping metal iron because material is relatively soft, expensive, easy to break and some Aluminum Alloy products also need subsequent processing, such as drawing, anode processing, especially in stamping production to produce top injuries, scratches, in the mold manufacturing should pay special attention to the following:1, for the project does not affect the number of cases, punching as far as possible behind the project, punching, and even for punching a large number of products, may consider more than one project, but also the punching line in the back.2, aluminum material is soft, and the mold is easy to block material, so in the design of mold gap should be put bilateral material thickness of 10% gap, the knife edge straight depth to 2MM is more appropriate, the taper to 0.8-1 degrees is appropriate.3, bending forming, because aluminum material in bending when easy to produce aluminum chip, will cause spot injury, indentation, aluminum raw material needs to stick PE film, in the roller and electroplating case, forming block with polishing hard chromium is better.4, the need for anode processing after stamping, such as pressing and flattening process of 180 degrees, the product can not be completely pressed, completely pressed will spit acid phenomenon for 0.2-0.3MM seam, acid to timely outflow, so we must do this step on the limiting block and calibration mode is higher than the norm out on.5, because the aluminum material is crisp, easy to crack, especially in the case of anti flanging, so try not to do the line, even if you want to do, but also to make the line width a little bit, a little lighter.6, all aluminum blade are required to use wire cut, to prevent the burrs and blanking is not smooth, easy to produce high temperature aluminum, so the punch hardness requirements of more than 60 degrees, at least with SKD11 material, has no D2 arithmetic matter punch.

- Q: Are aluminum profiles suitable for constructing energy-efficient buildings?

- <p>Yes, aluminum profiles can be used to create energy-efficient building designs. They are lightweight, strong, and have excellent thermal conductivity, which can be utilized to design structures with reduced heat transfer, thereby improving energy efficiency. Aluminum profiles can also be used in combination with insulating materials to enhance thermal insulation. Their recyclability and low maintenance requirements contribute to sustainability, further supporting energy-efficient construction practices.</p>

- Q: What are the fire-resistant properties of aluminum profiles?

- Aluminum profiles offer a range of fire-resistant qualities that render them suitable for a variety of uses. Firstly, aluminum boasts a remarkably high melting point of around 660 degrees Celsius (1220 degrees Fahrenheit), enabling it to endure extreme temperatures without succumbing to melting or compromising its structural integrity. Furthermore, aluminum possesses a low ignition point, necessitating a higher temperature than other metals to ignite. This attribute reduces the likelihood of aluminum catching fire when exposed to heat or flames. In the event of a fire, aluminum profiles generate a protective layer of aluminum oxide on their surface owing to their innate oxide layer. This layer acts as a barrier, impeding the propagation of flames and hindering the combustion process. Moreover, the aluminum oxide layer exhibits exceptional heat resistance, thereby providing supplementary defense against elevated temperatures. Additionally, aluminum profiles are non-combustible, meaning they do not contribute to the expansion of a fire. This characteristic assumes critical importance in ensuring fire safety by containing the fire within a specific zone and averting rapid spreading. Taken together, the fire-resistant attributes of aluminum profiles, encompassing their high melting point, low ignition point, the formation of a protective oxide layer, and non-combustibility, establish them as a dependable choice for a wide range of applications where fire safety is a paramount concern.

Send your message to us

Extruded Aluminum Profiles China - Alloy 6063, 6061, 6005 Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords