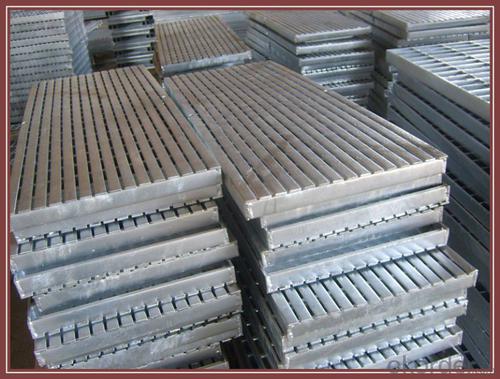

Pressed And Forged Aluminum Flooring Grating/Grate/Grates

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Do aluminum profiles have good thermal insulation properties?

- Aluminum profiles, unfortunately, lack good thermal insulation properties. Due to its high conductivity, aluminum readily permits heat transfer. Consequently, when it comes to preventing heat transfer and providing thermal insulation, aluminum profiles are less efficient compared to materials like wood or vinyl. To improve the thermal insulation capabilities of aluminum profiles, they are frequently combined with thermal breaks or insulating materials. This combination serves to minimize heat loss or gain.

- Q: This question asks if aluminum profiles can be utilized for constructing interior partitions or ceilings.

- <p>Yes, aluminum profiles are commonly used for interior partitions and ceilings due to their strength, durability, and lightweight properties. They offer design flexibility, are easy to install, and can be used in conjunction with various materials like glass or fabric. Additionally, aluminum profiles are resistant to corrosion and require minimal maintenance, making them a popular choice for both residential and commercial applications.</p>

- Q: Can aluminum profiles be used for greenhouse construction?

- Yes, aluminum profiles can be used for greenhouse construction. Aluminum is a popular choice for greenhouse frames due to its durability, lightweight nature, and resistance to corrosion. It is also easy to work with, allowing for flexibility in design and construction. Aluminum profiles provide a strong and stable structure that can withstand harsh weather conditions and provide long-term support for the greenhouse covering materials. Additionally, aluminum frames require minimal maintenance and have a longer lifespan compared to other materials, making them a cost-effective option for greenhouse construction.

- Q: How do aluminum profiles perform in terms of weather resistance?

- Aluminum profiles are known for their exceptional weather resistance. This is due to the inherent properties of aluminum, such as its corrosion resistance and ability to withstand harsh environmental conditions. Aluminum profiles are typically coated or anodized to further enhance their weather resistance, ensuring long-term durability and protection against various weather elements. Aluminum's corrosion resistance is particularly advantageous in outdoor applications. It forms a natural oxide layer when exposed to oxygen, which acts as a protective barrier against rust and deterioration. This makes aluminum profiles highly resistant to moisture, rain, and humidity, making them suitable for use in coastal areas or regions with high levels of precipitation. Furthermore, aluminum profiles are also resistant to UV radiation. The surface treatment, such as powder coating or anodizing, provides an additional layer of protection against the sun's harsh rays. This prevents the aluminum from fading, chipping, or cracking when exposed to prolonged sunlight, ensuring the profiles retain their original appearance and structural integrity over time. In terms of extreme weather conditions, aluminum profiles are designed to withstand high winds, extreme temperatures, and even severe storms. They have excellent mechanical properties, including high strength and stiffness, which enable them to withstand heavy loads and resist deformation. This makes aluminum profiles ideal for use in construction, architecture, and outdoor infrastructure projects where weather resistance is crucial. Overall, aluminum profiles perform exceptionally well in terms of weather resistance. Their natural corrosion resistance, combined with the various surface treatments available, ensures that they can withstand a wide range of weather conditions without losing their structural integrity or aesthetic appeal.

- Q: Household aluminum profiles, which brand of cost-effective? Recommend!

- Cost performance is better, in our Nanshan factory is called a good fight,

- Q: Can aluminum profiles be anodized for improved corrosion resistance?

- Aluminum profiles can undergo anodization to enhance their resistance to corrosion. Anodizing involves an electrochemical process that creates a protective layer of aluminum oxide on the metal's surface. This layer not only improves the appearance of the profile but also provides excellent corrosion resistance. During anodization, the aluminum profile is placed in an electrolytic solution and subjected to a direct current. This prompts oxidation to take place on the metal's surface, resulting in the formation of a thick layer of aluminum oxide. This oxide layer is tough, long-lasting, and firmly adheres to the underlying aluminum, effectively guarding against corrosion. The anodic oxide layer can be further fortified by sealing it using different methods, such as hot water sealing or chemical sealing. This serves to enhance the aluminum profile's resistance to environmental elements like moisture, chemicals, and UV radiation. Anodized aluminum profiles offer numerous advantages over non-anodized ones. They exhibit superior resistance to corrosion, scratches, and wear. Moreover, anodization can also create a decorative finish for the aluminum profile, as it allows for a wide array of colors to be applied. In conclusion, anodization is an extremely effective technique for boosting the corrosion resistance of aluminum profiles, making them suitable for various applications where protection against corrosion is crucial. These applications include the construction, automotive, aerospace, and electronics industries.

- Q: Can aluminum profiles be used in the construction of exhibition stands?

- Yes, aluminum profiles can be used in the construction of exhibition stands. Aluminum profiles are lightweight, versatile, and easy to work with, making them a popular choice for constructing exhibition stands. They can be easily shaped and customized to fit specific design requirements, and their durability ensures a long-lasting structure. Additionally, aluminum profiles can be powder-coated or anodized to provide a professional and attractive finish, enhancing the overall aesthetic appeal of the exhibition stand.

- Q: Excuse me, aluminum oxidation and electrophoresis have what different?

- Main features of high-grade electrophoresis aluminum:1, with a strong film hardness, impact resistance2, with a high adhesion to the film, not easy to fall off and aging3, aluminum oxide than the more strong wear resistance, weather resistance, alkali resistance4, the surface color is rich, beautiful, has the mirror like luster effectAluminum electrophoresis processing in oxidized aluminum on the basis of better quality than the oxidized aluminum chip. The price is relatively good point.

- Q: Can aluminum profiles be used for soundproofing?

- Aluminum profiles have the ability to offer some soundproofing benefits, although they may not provide the same level of sound reduction as specialized soundproofing materials like acoustic panels or insulation. These profiles are commonly used in the construction industry for various purposes, such as window frames and door frames. When incorporated into soundproofing applications, aluminum profiles can effectively minimize noise transmission through windows and doors. The lightweight and durable nature of aluminum makes it an ideal material for blocking or dampening sound waves. Its structural integrity allows for the creation of tight seals, resulting in reduced sound leakage and improved sound insulation. To further enhance soundproofing, aluminum profiles can be combined with other materials like rubber gaskets or weatherstripping. This combination enhances the sealing properties and contributes to better sound insulation. Additionally, the use of double or triple glazing with laminated glass in conjunction with aluminum profiles can provide even better sound insulation. However, it is important to consider that the effectiveness of aluminum profiles in soundproofing depends on various factors. These factors include the thickness and quality of the profiles, the design of the window or door system, and the overall construction of the building. In conclusion, while aluminum profiles can assist in reducing noise transmission through windows and doors, they should be viewed as part of a comprehensive soundproofing strategy rather than the sole solution.

- Q: Are aluminum profiles suitable for interior design applications?

- Aluminum profiles are appropriate for interior design applications, offering numerous benefits in this field. Firstly, they are lightweight yet sturdy, facilitating easy installation and working processes. This grants designers the freedom to create intricate shapes and structures, adding flexibility to their designs. Moreover, aluminum possesses exceptional durability and resistance to rust and corrosion. Consequently, it is ideal for a wide range of interior design applications, including door frames, window frames, partitions, cabinets, and furniture. The ability of aluminum profiles to withstand wear and tear guarantees longevity and reduces maintenance requirements. Furthermore, aluminum profiles provide customization options and can be finished in various ways. They can be powder-coated or anodized, allowing for the achievement of different colors and textures. This versatility enhances the design possibilities and enables the creation of unique and aesthetically pleasing interiors. Additionally, aluminum is an environmentally friendly material that supports sustainability. It is highly recyclable and requires significantly less energy for production compared to other metals. Consequently, it aligns with the growing trend of eco-conscious design, making it a responsible choice for interior design applications. In conclusion, aluminum profiles are unquestionably suitable for interior design purposes. Their lightweight nature, durability, customization options, and sustainability aspects make them an ideal choice for creating functional and visually appealing interiors.

Send your message to us

Pressed And Forged Aluminum Flooring Grating/Grate/Grates

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords