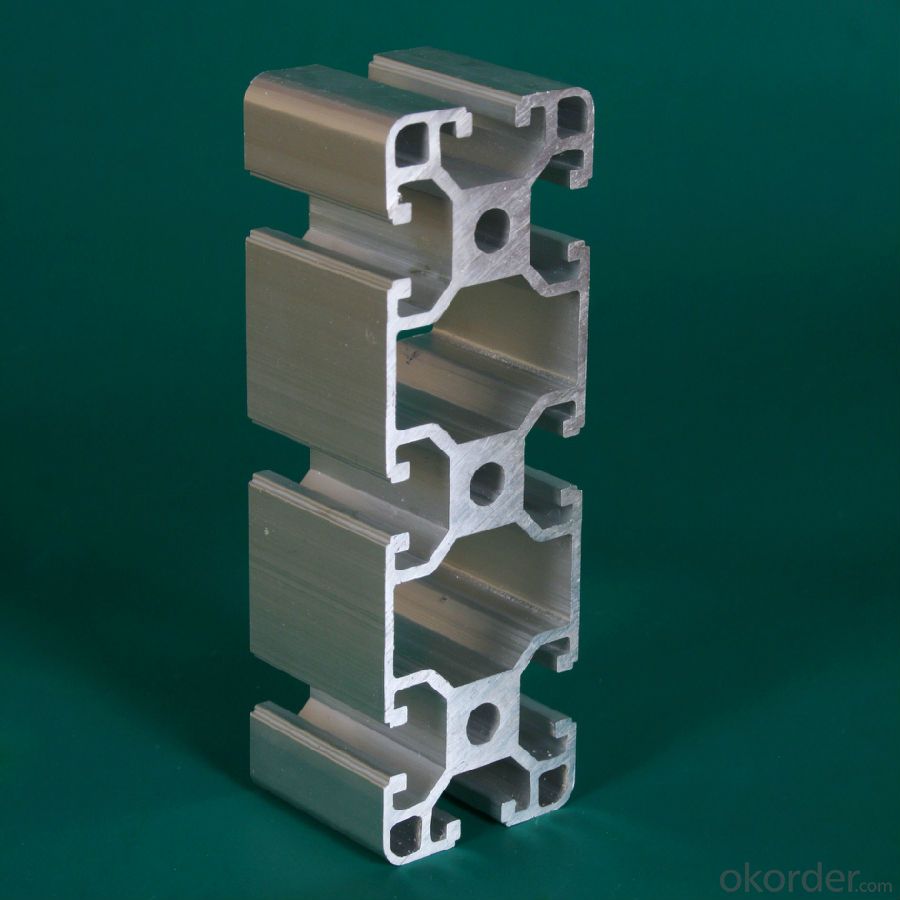

China Powder Coated Aluminum Profiles - Alloy 6063 Aluminium Extrusion Profiles for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Product Name | Alloy 6063 Aluminium Extrusion Profiles For Construction |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: This question asks about the variety of colors offered for aluminum profiles used in exterior siding and trim applications.

- <p>Aluminum profiles for siding and trimming are available in a wide range of colors to suit various architectural styles and design preferences. Common colors include white, black, brown, beige, and gray, which are popular for their neutrality and versatility. Additionally, there are bolder options such as red, blue, green, and yellow for more distinctive looks. Some manufacturers also offer custom color matching services for specific projects. The finishes can be powder-coated or anodized, providing durability and resistance to weathering. It's always best to check with specific manufacturers for the most up-to-date color offerings as they may introduce new colors or discontinue others based on market trends.</p>

- Q: Are aluminum profiles suitable for food processing applications?

- Aluminum profiles prove to be a fitting option for food processing applications. Aluminum, being a lightweight and corrosion-resistant material, finds extensive use in the food processing industry due to its numerous advantages. To begin with, aluminum profiles possess easy-to-clean and maintain properties, which are crucial in food processing environments where hygiene holds utmost importance. They can be effortlessly washed and sterilized, preventing any potential cross-contamination or bacterial growth. Moreover, aluminum is non-toxic and does not react with food or beverages, ensuring that the processed products' integrity and quality remain uncompromised. This aspect gains particular significance when dealing with acidic or alkaline foods that may react with other materials. Additionally, aluminum profiles exhibit exceptional thermal conductivity, facilitating efficient heat transfer during processing operations like baking or cooling. This feature guarantees uniform heat distribution, resulting in consistent outcomes. Furthermore, aluminum stands as a sustainable material that can be recycled repeatedly without losing its properties. This aspect aligns with the growing emphasis on sustainability and environmental responsibility in the food processing industry. In conclusion, the attributes of aluminum profiles render them a suitable choice for food processing applications, offering durability, cleanliness, and compatibility with food products.

- Q: This question asks about the various types of aluminum profiles that are utilized specifically for constructing wall frames.

- <p>Aluminum profiles for wall frames come in various types, each serving specific purposes. Common types include: 1) Structural profiles, which provide the main support and strength to the frame; 2) Cover profiles, used to conceal joints and fasteners, enhancing the aesthetic appeal; 3) Insulation profiles, designed to provide thermal insulation; 4) Glazing profiles, used to hold glass or other transparent materials in place; 5) Corner profiles, for joining two walls at a right angle; 6) Sealing profiles, to ensure weatherproofing and airtightness; and 7) Special profiles, tailored for unique architectural designs or specific functions. Each type is chosen based on the structural requirements, design aesthetics, and performance needs of the wall system.</p>

- Q: Can aluminum profiles be used in the construction of exhibition booths?

- Yes, aluminum profiles can be used in the construction of exhibition booths. Aluminum profiles are lightweight, durable, and versatile, making them an ideal choice for constructing modular exhibition booths. These profiles can be easily assembled and disassembled, allowing for easy transportation and reconfiguration of the booth layout. Additionally, aluminum profiles offer a sleek and modern aesthetic, providing a professional and visually appealing display for exhibitors. They can be used to create frames, partitions, shelving, signage, and various other components required for exhibition booths. Overall, aluminum profiles offer a cost-effective and efficient solution for constructing exhibition booths.

- Q: What is the difference between aluminum profile and sheet metal?

- Aluminum extrusions can be produced by extrusion or casting. In contrast, the aluminum sheet is flat, mainly for all types of surface.

- Q: Can aluminum profiles be used in electrical enclosure manufacturing?

- Certainly, the utilization of aluminum profiles is feasible for the manufacturing of electrical enclosures. Aluminum, being a flexible and lightweight material, presents numerous advantages for such enclosures. Its high conductivity ensures effective dissipation of heat, a vital feature for electronic components that generate heat while functioning. Moreover, aluminum exhibits exceptional resistance to corrosion, guaranteeing that the enclosure can endure even the harshest environmental conditions and prolong its lifespan. In addition, customization and fabrication of aluminum profiles to meet specific design requirements are easily achievable, making them suitable for various enclosure sizes and shapes. All in all, due to their remarkable conductivity, durability, and versatility, aluminum profiles are a favored option for electrical enclosure manufacturing.

- Q: Can aluminum profiles be utilized in creating distinctive architectural designs and styles?

- <p>Yes, aluminum profiles can be used to create unique architectural designs and styles. They are favored for their strength, durability, and versatility. Architects can manipulate aluminum to achieve a wide range of shapes and structures, from sleek modern designs to traditional styles with a contemporary twist. Aluminum's lightweight nature and resistance to corrosion make it an ideal material for both interior and exterior applications, allowing for creative freedom in architectural expression.</p>

- Q: How do you prevent galling or seizing with aluminum profiles?

- To prevent galling or seizing with aluminum profiles, there are a few measures you can take: 1. Lubrication: Apply a suitable lubricant to the contact surfaces of the aluminum profiles. This reduces friction and heat generation, which helps prevent galling or seizing. Choose a lubricant specifically designed for aluminum to avoid any adverse reactions. 2. Surface treatment: Implement surface treatments such as anodizing or applying a protective coating to the aluminum profiles. These treatments create a barrier between the profiles, reducing direct metal-to-metal contact and minimizing the chances of galling or seizing. 3. Proper design and materials: Ensure the design of the profiles and their mating components allows for sufficient clearance and proper fit. Avoid tight tolerances that can lead to excessive contact pressure, increasing the likelihood of galling. Additionally, select materials with compatible hardness and avoid using dissimilar metals that can lead to galvanic corrosion. 4. Cleanliness: Keep the aluminum profiles and their mating surfaces clean and free from dirt, debris, or contaminants. Any foreign particles can increase friction and contribute to galling or seizing. 5. Regular maintenance: Implement a preventive maintenance program that includes periodic inspection, cleaning, and lubrication of the aluminum profiles. This helps identify any issues early on and ensures continued smooth operation. By following these preventive measures, you can minimize the risk of galling or seizing in aluminum profiles, ensuring their longevity and optimal performance.

- Q: Can aluminum profiles be used in load-bearing structures?

- Aluminum profiles are indeed applicable in load-bearing structures. With its lightweight and remarkable durability, aluminum possesses an exceptional strength-to-weight ratio that renders it suitable for diverse load-bearing applications. The profiles can be customized and produced to endure significant loads, making them an ideal choice for bridges, buildings, and industrial frameworks. Additionally, aluminum profiles exhibit corrosion-resistant properties, further enhancing their suitability for load-bearing structures in different environments. Nevertheless, it is crucial to carefully consider the specific design needs, load circumstances, and accurate engineering calculations to guarantee that the aluminum profiles are appropriately sized and reinforced for their intended load-bearing purposes.

- Q: Measuring 3 meters long aluminum profiles of the straightness, you have what good method? What is the maximum deviation value allowed by our industry? In addition to the platform measurement, and what are the economic and practical methods, our factory stalls are small. Consider input costs.

- The friend the profiles of the straightness, don't know you mean curvature profile, or twist, there are clear provisions in the building material standard GB5237-2008 and GB/T6892-2006 standard in all industrial sections, such as building materials in the standard GB5237-2008, the bending degree is divided into ordinary grade, high grade, high precision class.

Send your message to us

China Powder Coated Aluminum Profiles - Alloy 6063 Aluminium Extrusion Profiles for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords