Adjustable Arced Steel Formwork for Circle Column Pouring

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

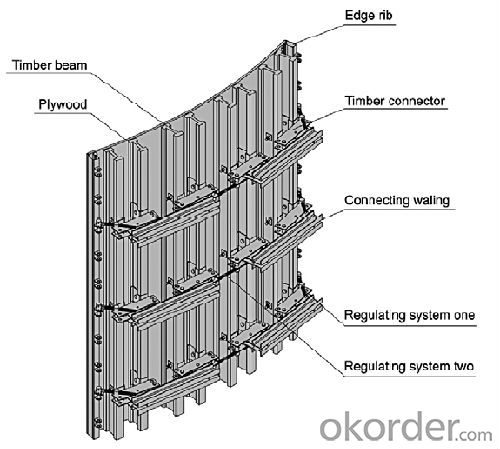

1. Structure of Curve Concrete Wall Formwork

TBW system-C is a kind of formwork for pouring curve wall, it is composed of several pieces of Tim-formwork, tie rod, wing nut, etc.

It will be designed according to wall’s size.

2. Main Features of Curve Concrete Wall Formwork

1. Quickly construction with TBW system-C.

2. Light weight but high bearing capacity.

For conventional design, its load bearing capacity is 60KN/m2 with weight of 60-80kg/m2. If required, the formwork can be specially designed for higher concrete pressures.

3. Timber is easy re-sized, so the Tim-formwork is relatively easier to change self’s size and shape. This approved formwork’s economical efficiency.

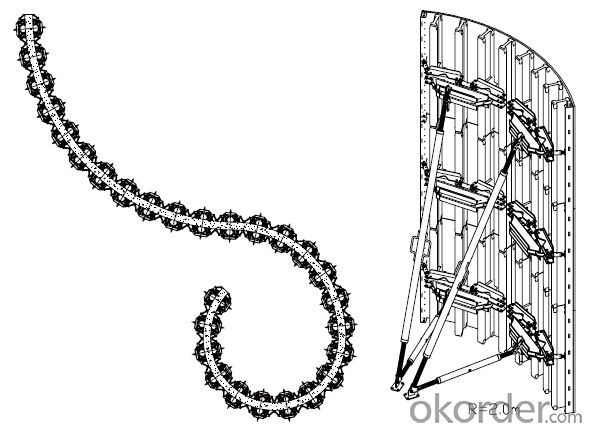

3. Curve Concrete Wall Formwork Images

4. Curve Concrete Wall Formwork Specification

5. FAQ of Curve Concrete Wall Formwork

1) What can we do for you?

We can ensure the quality of the Curve Concrete Wall Formwork and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Curve Concrete Wall Formwork, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of Curve Concrete Wall Formwork, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: What are the common durability issues with steel formwork systems?

- There are several common durability issues that can arise with steel formwork systems. One of the main concerns is corrosion, which occurs when the steel comes into contact with moisture or aggressive chemicals. Corrosion can weaken the structural integrity of the formwork system and lead to premature failure if not properly addressed. Another durability issue is wear and tear. Steel formwork systems are often subjected to repeated use, which can result in surface damage and deformation over time. This can lead to difficulties in achieving accurate and precise concrete finishes, as well as pose safety risks for workers. Additionally, improper handling and storage of steel formwork systems can result in bending or warping of the components. This can affect the overall stability and effectiveness of the system, making it less durable and reliable. Finally, inadequate maintenance and lack of proper protective coatings can contribute to durability issues. Regular inspections, cleaning, and applying protective coatings can help prevent corrosion and extend the lifespan of the steel formwork system. In conclusion, common durability issues with steel formwork systems include corrosion, wear and tear, improper handling and storage, and inadequate maintenance. It is crucial to address these issues promptly and implement proper maintenance practices to ensure the longevity and effectiveness of the formwork system.

- Q: How does steel formwork compare to plastic formwork?

- Steel formwork is generally more durable and long-lasting compared to plastic formwork. It can withstand heavy loads and provides better stability and support during the concrete pouring process. Additionally, steel formwork is reusable and can be easily adjusted and customized according to project requirements. On the other hand, plastic formwork is lighter and easier to handle, making it more suitable for small-scale projects. However, it may not be as sturdy and may require more frequent replacements.

- Q: Can steel formwork be used in renovation and refurbishment projects?

- Yes, steel formwork can be used in renovation and refurbishment projects. Steel formwork is versatile and durable, making it suitable for various construction applications, including renovations and refurbishments. It provides structural support and helps ensure precise and accurate concrete shaping during the renovation process. Additionally, steel formwork can be reused multiple times, making it cost-effective for projects that require frequent alterations or modifications.

- Q: What are the common cost-saving strategies when using steel formwork?

- There exist several commonly employed strategies for cost reduction when utilizing steel formwork in construction projects. 1. Reusability: Steel formwork's ability to be reused multiple times is one of its key advantages. By properly maintaining and storing the formwork after each use, it can be utilized for multiple projects, thereby lessening the need for new formwork and ultimately resulting in cost savings. 2. Durability: Steel formwork is renowned for its durability and long lifespan. It can withstand high pressures and be utilized for an extended duration compared to traditional formwork materials such as timber. This durability decreases the necessity for frequent repairs or replacements, leading to long-term cost savings. 3. Efficiency: Steel formwork facilitates faster and more efficient construction in comparison to traditional formwork methods. The ease of assembly and disassembly, coupled with the use of hydraulic systems, enables swifter construction cycles and reduces labor costs. Furthermore, the precision and accuracy of steel formwork ensure minimal material wastage, further contributing to cost savings. 4. Safety: Steel formwork provides enhanced safety features when compared to other formwork materials. It offers stability and structural integrity, thereby reducing the risk of accidents during the construction process. A safer working environment translates to lower insurance costs and potential legal liabilities, resulting in cost savings. 5. Reduced labor costs: Steel formwork is typically lighter and easier to handle than alternative materials. This diminishes the number of workers required for installation and removal. Additionally, the speed and efficiency of steel formwork result in reduced labor hours, leading to cost savings. 6. Lower maintenance costs: Steel formwork necessitates minimal maintenance when compared to other formwork materials. Regular cleaning and appropriate storage are typically sufficient to maintain its performance. This eliminates the need for expensive maintenance or repairs, resulting in cost savings over time. 7. Improved quality: Steel formwork ensures consistent quality in construction. It provides accurate dimensions and smooth finishes, reducing the need for additional finishing work. This saves both time and money, as there is no requirement for additional materials or labor to rectify imperfections. In conclusion, the employment of steel formwork in construction projects allows for numerous cost-saving strategies, including reusability, durability, efficiency, safety, reduced labor costs, lower maintenance costs, and improved quality. By considering and implementing these strategies, construction projects can optimize their budget and achieve significant cost savings.

- Q: Can steel formwork be used for soundproofing walls?

- Steel formwork is primarily used for creating the structure and shape of concrete walls during construction. While steel formwork is sturdy and durable, it is not specifically designed for soundproofing purposes. Soundproofing walls typically require materials with high acoustic performance and insulation properties to effectively block or absorb sound waves. While steel formwork may offer some level of sound reduction due to its density, it is not sufficient for achieving significant soundproofing results. To effectively soundproof walls, it is recommended to use specialized materials such as acoustic insulation, mass-loaded vinyl, or soundproof drywall, which are designed specifically for this purpose.

- Q: How does steel formwork affect the overall thermal insulation of a building?

- Steel formwork does not directly impact the overall thermal insulation of a building. The purpose of steel formwork is to provide structural support during the construction process, allowing the concrete to be poured and shaped into the desired form. It is a temporary structure that is removed after the concrete has cured. Thermal insulation in a building is primarily determined by the materials used in the walls, roof, and floors, as well as the design and installation of insulation systems. These materials and systems are separate from the steel formwork used during construction. However, it is worth noting that the use of steel formwork may have an indirect effect on the thermal insulation of a building. The construction process itself, including the use of formwork, can impact the overall quality of the insulation installation. If not properly managed, the installation of insulation materials during or after the removal of steel formwork may be compromised, leading to gaps, voids, or poor installation that can affect thermal insulation. Therefore, it is essential to ensure that proper construction practices are followed, and insulation materials are correctly installed after the removal of steel formwork. This will help maintain the intended thermal insulation performance of the building.

- Q: What are the different types of coatings available for steel formwork panels?

- There are several types of coatings available for steel formwork panels, each offering unique benefits and applications. 1. Galvanized Coating: This is one of the most common types of coatings used for steel formwork panels. It involves applying a layer of zinc to the surface of the steel through a process called galvanization. Galvanized coatings provide excellent corrosion resistance, making them suitable for outdoor and high-moisture environments. 2. Epoxy Coating: Epoxy coatings are known for their superior chemical and abrasion resistance. They are applied as a two-part system that combines resin and a hardener. Epoxy coatings create a strong, durable surface that can withstand heavy use and exposure to various chemicals. They are often used in industrial settings or where high performance is required. 3. Polyurethane Coating: Polyurethane coatings offer excellent resistance to abrasion, impact, and weathering. They are commonly used in applications where a high level of durability is needed, such as in construction projects or infrastructure development. Polyurethane coatings also provide good adhesion to the steel surface, ensuring long-lasting protection. 4. Powder Coating: Powder coating is a dry finishing process where a fine powder is electrostatically applied to the steel surface. It is then cured under heat to form a hard, protective layer. Powder coatings come in a wide range of colors and provide excellent resistance to chipping, scratching, and fading. They are commonly used for aesthetic purposes or in applications where a decorative finish is desired. 5. Zinc-rich Coating: Zinc-rich coatings are similar to galvanized coatings, but they contain a higher concentration of zinc particles. These coatings provide enhanced corrosion protection and are often used in highly corrosive environments, such as marine or coastal areas. Zinc-rich coatings can be applied either by spraying or brushing. 6. Fire-resistant Coating: Fire-resistant coatings are specifically designed to provide protection against the spread of fire. These coatings create a barrier that delays the heating of steel, helping to prevent the structural collapse of a building during a fire. Fire-resistant coatings are commonly used in commercial and industrial buildings, as well as in infrastructure projects. It is important to consider the specific requirements of the project and consult with experts to determine the most suitable coating for steel formwork panels. Factors such as the environment, expected durability, and budget should be taken into account to ensure optimal performance and longevity.

- Q: Can steel formwork be customized for different project requirements?

- Yes, steel formwork can be customized to meet different project requirements. Steel is a versatile material that can be easily shaped and modified to fit specific project needs. It can be cut, welded, and adjusted to create formwork in various shapes and sizes, allowing it to be tailored to different construction projects. Additionally, steel formwork can be reused multiple times, making it a cost-effective and sustainable solution for customized construction requirements.

- Q: How does steel formwork handle different concrete workability levels?

- Steel formwork is a flexible and long-lasting material that effectively handles various levels of concrete workability. Workability refers to how easily concrete can be mixed, placed, compacted, and finished. When dealing with different workability levels in concrete, steel formwork offers several advantages. Firstly, its sturdy and rigid structure can withstand the pressure exerted by concrete during pouring and compaction. This ensures that the formwork remains stable and does not deform or collapse under the weight of the concrete. Furthermore, steel formwork provides a smooth and uniform surface for the concrete, regardless of its workability. This is crucial for achieving a high-quality finish and minimizing defects like honeycombing or uneven surfaces. The smoothness of steel formwork allows for easy and efficient removal, ensuring that the concrete retains its shape and integrity. Moreover, steel formwork can be easily customized and adjusted to accommodate different workability levels. Its modular nature allows for easy assembly and disassembly, making it suitable for various construction projects and types of concrete. Steel formwork can be adjusted to fit changes in concrete consistency, ensuring that the formwork remains tight and secure. This adaptability is particularly beneficial when working with concrete mixes that have different slump values or consistencies. Another advantage of steel formwork is its reusability. Unlike other forms of formwork, such as wood or plastic, steel formwork can be used multiple times without compromising its structural integrity. This not only reduces construction costs but also allows for efficient handling of concrete with different workability levels. Steel formwork can be easily cleaned, repaired, and reused, making it a cost-effective and sustainable choice for handling various levels of concrete workability. In conclusion, steel formwork provides a dependable and flexible solution for handling different levels of concrete workability. Its strength, smoothness, adjustability, and reusability make it an ideal choice for ensuring the stability, quality, and efficiency of concrete construction projects.

- Q: How does steel formwork compare to plastic formwork in terms of cost and durability?

- Steel formwork generally tends to be more expensive than plastic formwork due to the higher cost of steel as a material. However, steel formwork offers better durability and longevity compared to plastic formwork. Steel can withstand heavy loads and repetitive use, making it more suitable for large-scale construction projects. While plastic formwork may be more cost-effective for smaller and temporary projects, steel formwork is a more cost-efficient and durable option for long-term use.

Send your message to us

Adjustable Arced Steel Formwork for Circle Column Pouring

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords