Steel-frame formwork SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

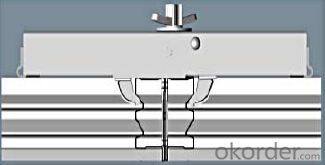

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be easily modified or adjusted during construction?

- Yes, steel formwork can be easily modified or adjusted during construction. Steel is a highly versatile material that can be cut, welded, or reshaped to fit different requirements. This flexibility allows for quick modifications or adjustments to the formwork system, making it a practical choice for construction projects that require frequent changes or adaptations.

- Q: Are there any regulations or standards that govern the use of steel formwork?

- Steel formwork in construction projects is subject to regulations and standards to guarantee safety, quality, and durability. The American National Standards Institute (ANSI) A10.9-2013 standard is widely recognized for safety requirements in concrete and masonry construction. It provides guidelines for formwork usage, including steel formwork, covering design, construction, inspection, and maintenance. Beside ANSI, the Occupational Safety and Health Administration (OSHA) in the United States and the Health and Safety Executive (HSE) in the United Kingdom establish regulations and guidelines for safe steel formwork utilization. These regulations encompass worker safety, proper assembly and dismantling procedures, and the use of suitable protective equipment. Furthermore, international standards like ISO 9001:2015 for quality management systems are applicable to steel formwork manufacturing and installation processes. These standards guarantee that the steel formwork meets specific quality and performance criteria. Construction companies and contractors must comply with these regulations and standards to ensure worker safety and project success. Noncompliance can lead to penalties, legal issues, and on-site accidents. Consequently, staying up-to-date with the latest regulations and standards related to steel formwork is crucial and their implementation is vital.

- Q: Are there any special considerations when using steel formwork in cold weather conditions?

- Yes, there are several special considerations when using steel formwork in cold weather conditions. Firstly, steel can become brittle at low temperatures, so it is important to ensure that the formwork is adequately heated to prevent cracking or structural failures. Additionally, cold temperatures can affect the curing process of concrete, so it is necessary to use temperature-controlled curing techniques and ensure proper insulation of the formwork. Lastly, freezing temperatures can cause ice to form on the formwork, which may affect the quality of the finished concrete. Therefore, it is crucial to regularly inspect and remove any ice buildup to maintain the integrity of the steel formwork.

- Q: Can steel formwork be used for both monolithic and composite construction?

- Yes, steel formwork can be used for both monolithic and composite construction.

- Q: How much weight can steel formwork support?

- The weight that steel formwork can support depends on various factors such as the size and thickness of the steel, the design of the formwork, and the supporting structure. Generally, steel formwork is capable of supporting heavy loads ranging from a few hundred kilograms to several tonnes.

- Q: How does steel formwork prevent concrete bleeding?

- Steel formwork is a type of temporary structure that is used in construction to hold and shape the concrete until it sets and hardens. One of the advantages of using steel formwork is that it can help prevent concrete bleeding, which is the process of water separating from the mixture and rising to the surface. Steel formwork is typically designed with tight joints and smooth surfaces, which helps to create a watertight seal around the concrete. This prevents water from seeping out of the mixture and rising to the surface, reducing the occurrence of concrete bleeding. Additionally, the rigid nature of steel formwork prevents the concrete from settling or shifting during the pouring process, further minimizing the potential for bleeding. Furthermore, steel formwork offers better stability and durability compared to other types of formwork materials. Its rigid structure ensures that the formwork remains intact and maintains the desired shape during the concrete pouring process, preventing any movement that could lead to bleeding. In conclusion, steel formwork prevents concrete bleeding by providing a tight seal, stability, and a smooth surface. These features prevent water from separating from the mixture and rising to the surface, resulting in a higher quality and more visually appealing concrete finish.

- Q: What are the limitations of using steel formwork?

- There are several limitations of using steel formwork in construction projects. Firstly, steel formwork is relatively expensive compared to other types of formwork materials such as wood or aluminum. This can significantly increase construction costs, especially for large-scale projects. Secondly, steel formwork is heavy and requires heavy machinery and equipment for transportation and installation. This can be challenging in areas with limited access or on sites with uneven terrain. Additionally, steel formwork requires skilled labor for proper installation and dismantling. This can create delays and increase labor costs if the workforce is not experienced in working with steel formwork. Moreover, steel formwork is not as flexible as other types of formwork materials. It may not be suitable for complex or irregular shapes, which can limit design possibilities. Another limitation is the potential for corrosion. Steel formwork is vulnerable to rust and corrosion, especially in environments with high moisture or chemical exposure. Regular maintenance and corrosion protection measures are essential to ensure the longevity of steel formwork. Lastly, steel formwork is not as environmentally friendly as other alternatives. Steel production involves significant energy consumption and carbon emissions, which can contribute to environmental degradation. Overall, while steel formwork offers strength and durability, its limitations in terms of cost, weight, flexibility, corrosion susceptibility, and environmental impact should be carefully considered before choosing it for construction projects.

- Q: How does steel formwork handle different concrete workability levels?

- Steel formwork is a versatile solution that can easily handle different concrete workability levels. Its rigid and durable structure ensures that it can withstand the pressure and weight of concrete, regardless of its consistency. Steel formwork provides a stable and secure framework, allowing for the pouring and shaping of concrete into various shapes and designs, even if the workability level varies.

- Q: Can steel formwork be used for residential tower construction projects?

- Residential tower construction projects can indeed utilize steel formwork. Steel formwork has gained popularity within the construction industry due to its durability and versatility. Its robustness makes it an ideal choice for high-rise structures like residential towers, as it can endure high concrete pressures and deliver a seamless finish. One of the main advantages of steel formwork is its reusability, making it a cost-effective solution for large-scale projects. It is easily assembled and disassembled, enabling efficient construction schedules. Moreover, it provides exceptional support during concrete pouring and setting, ensuring accurate dimensions and alignment. Residential tower projects often require swift construction cycles, and steel formwork facilitates this by allowing for rapid and efficient concrete pouring and formwork removal. Additionally, it reduces reliance on highly skilled labor, as it can be effortlessly handled and manipulated. Nevertheless, it is crucial to consider the specific requirements and design considerations of each residential tower project. Factors such as tower height, load-bearing capacity, and architectural design may influence the suitability of steel formwork. Consulting with a structural engineer or construction professional is highly recommended to determine the most suitable formwork system for a specific residential tower construction project.

- Q: How does steel formwork affect the overall fire resistance of a structure?

- The overall fire resistance of a structure is not directly affected by steel formwork, as its main purpose is temporary support during concrete pouring and construction. The fire resistance of a structure is generally determined by the construction materials, including the type of concrete, insulation, and fireproofing systems. However, steel formwork can indirectly contribute to the fire resistance by ensuring proper placement and compaction of the concrete, which is crucial for achieving the desired fire resistance rating. When mixed and compacted correctly, the strength and durability of the concrete can improve the overall fire resistance of the structure. Moreover, steel formwork can provide a smooth and uniform surface finish, which facilitates the application of fireproofing materials. Fireproofing coatings or sprays are often used to enhance the fire resistance of structural elements like beams and columns. The smooth surface offered by steel formwork helps ensure an even and effective application of these fireproofing materials, thus further improving the fire resistance of the structure. It is important to remember that although steel formwork itself is not fire resistant, it is usually removed once the concrete has cured. The final fire resistance of the structure is determined by the materials used in its permanent construction.

Send your message to us

Steel-frame formwork SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords