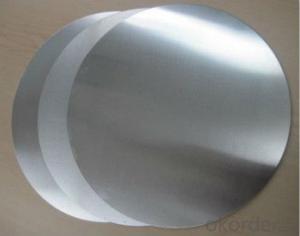

Aluminum Circle For Cookware

Aluminum Circle For Cookware Related Searches

Cooking Aluminium Circle Aluminum Circle Pan Aluminum Circle Aluminum Tray Circle Circle Aluminum Aluminium Circle Brushed Aluminum Circle Aluminum Sheet Circle Wholesale Aluminum Circle Aluminum Cooking Plate Circle Brushed Aluminum Aluminum Circle Sheet Aluminum Round Plate Circular Aluminum Plate Aluminum Foil For Cake Pan Cooking Aluminum Foil Cook With Aluminum Foil Cooking Using Aluminum Foil Aluminum Spinning Plate Aluminum Cake Plate Aluminum Foil For Baking Aluminum Foil For Food Aluminum Foil For Cake Aluminum Foil For Stove Aluminum Foil In Cake Pan Cook In Aluminum Foil Aluminum Grill Plate Aluminum Caul Plate Aluminum Angle Plate Aluminum Triangle PlateAluminum Circle For Cookware Supplier & Manufacturer from China

Aluminum Circle For Cookware is a versatile and essential product in the culinary industry, known for its lightweight, durability, and excellent heat conductivity. These circles, made from high-quality aluminum, are designed to be the foundation of various cookware items, such as pans, pots, and baking sheets, ensuring even heat distribution and efficient cooking. The usage of aluminum circles in cookware is widespread, as they cater to both commercial and residential kitchens, providing a reliable and efficient solution for cooking needs. Their ability to withstand high temperatures and resist corrosion makes them an ideal choice for professional chefs and home cooks alike.Okorder.com is a leading wholesale supplier of Aluminum Circle For Cookware, boasting a vast inventory that caters to the diverse needs of the market. As a trusted provider, Okorder.com ensures that customers receive top-quality aluminum circles that meet the highest industry standards. Their commitment to excellence and customer satisfaction has made them a go-to source for businesses and individuals alike who require aluminum circles for their cookware needs. With a wide range of sizes and thicknesses available, Okorder.com's Aluminum Circle For Cookware is the perfect choice for those looking to elevate their cooking experience.

Hot Products