Steel-frame formwork for corner

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

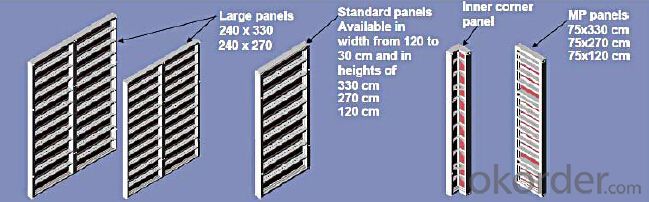

◆ The selection of panels.

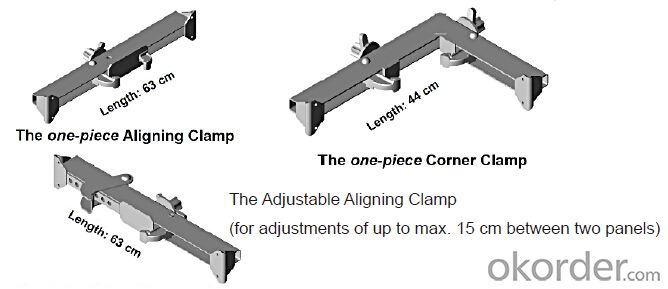

◆ Kinds of panel connectors.

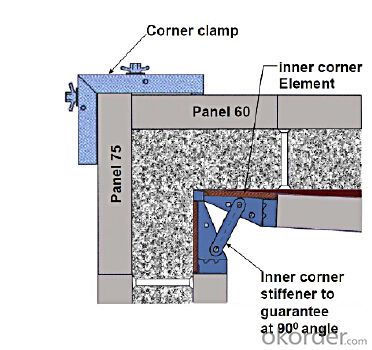

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: What are the different types of concrete finishes achievable with steel formwork?

- There are several different types of concrete finishes that can be achieved with steel formwork, including smooth finishes, textured finishes, exposed aggregate finishes, and stamped finishes. Each finish can be customized to achieve the desired aesthetic and texture for the concrete surface.

- Q: Can steel formwork be used in areas with limited construction access roads?

- Areas with limited construction access roads can indeed make use of steel formwork. Steel formwork is renowned for its robustness and longevity, rendering it suitable for a variety of construction sites, even those with restricted access. In contrast to timber or aluminum, steel formwork exhibits exceptional resilience and can bear heavy loads, making it an optimal selection for demanding construction endeavors. Furthermore, steel formwork can be easily transported and assembled on-site, enabling construction teams to surmount limitations posed by access roads and operate efficiently in remote or hard-to-reach regions. Consequently, steel formwork emerges as a feasible alternative for construction projects in areas with limited construction access roads.

- Q: What are the disadvantages of using steel formwork?

- One disadvantage of using steel formwork is its relatively high cost compared to other types of formwork materials. Additionally, steel formwork is heavy and requires special equipment for handling and installation, making it less convenient to transport and set up on construction sites. Moreover, steel formwork needs to be properly maintained to prevent rusting and corrosion, which adds to the overall maintenance cost. Lastly, steel formwork may not be suitable for complex and intricate architectural designs that require flexible formwork systems.

- Q: Can steel formwork be used for concrete walls and columns?

- Concrete walls and columns can indeed utilize steel formwork. This formwork option is widely favored for such purposes due to its enduring nature, robustness, and capacity for reuse. It enables the precise formation and alignment of concrete structures, yielding a superior end result. Steel formwork can withstand the pressure exerted by wet concrete and offer the crucial support needed during the curing stage. Furthermore, it resists warping, shrinking, and swelling, ensuring reliable outcomes across multiple pours. Nevertheless, the cost of steel formwork warrants consideration, as it typically exceeds that of alternative formwork types.

- Q: Can steel formwork withstand extreme weather conditions?

- Yes, steel formwork is designed to withstand extreme weather conditions. Steel is known for its strength and durability, making it highly resistant to harsh weather elements such as heavy rain, strong winds, and high temperatures. Additionally, steel formwork is often treated with protective coatings to further enhance its resistance to corrosion and degradation caused by extreme weather conditions.

- Q: What are the considerations when designing steel formwork for underground utilities?

- When designing steel formwork for underground utilities, there are several important considerations to keep in mind. Firstly, the formwork must be able to withstand the pressure and weight of the surrounding soil and any potential water infiltration. It is crucial to ensure that the formwork is strong and stable enough to prevent any collapse or deformation during and after the pouring of concrete. Secondly, the formwork design should allow for easy installation and removal. Accessibility and maneuverability are key factors, as underground utilities can often be located in tight spaces or areas with limited access. The formwork should be designed in such a way that it can be easily assembled and disassembled without causing damage to the surrounding infrastructure. Additionally, the formwork needs to be corrosion-resistant to withstand the potentially corrosive environment of underground utilities. Steel formwork should be properly coated or treated to prevent rust and deterioration over time. Lastly, consideration should be given to the formwork's compatibility with other construction materials and techniques. The design should integrate well with other components of the underground utility system and accommodate any necessary connections or interfaces. Overall, the design of steel formwork for underground utilities requires careful attention to strength, stability, accessibility, corrosion resistance, and compatibility with other construction elements.

- Q: What are the common safety guidelines when working with steel formwork?

- To ensure the well-being of workers and prevent accidents, it is important to adhere to several common safety guidelines when working with steel formwork. These guidelines encompass the following: 1. Utilizing Personal Protective Equipment (PPE): Workers must wear the appropriate PPE, which includes safety helmets, safety glasses, gloves, and steel-toed boots. This will safeguard them against potential hazards such as falling objects and cuts. 2. Emphasizing Training and Competency: Workers should undergo thorough training on the proper usage and handling of steel formwork. They should possess the necessary knowledge and skills to safely perform their assigned tasks. 3. Conducting Inspections: Regular inspections of the steel formwork must be carried out prior to and during its use. The objective is to ensure that it is in good condition and free from defects. Any damaged or faulty parts should be promptly repaired or replaced. 4. Employing Proper Handling Techniques: Due to the weight and unwieldiness of steel formwork, it is imperative to utilize correct lifting techniques and mechanical aids when moving or positioning it. This will prevent musculoskeletal injuries caused by excessive strain or overexertion. 5. Ensuring Secure Installation: The formwork must be securely installed and braced to prevent collapse or displacement during the pouring of concrete. It should be aligned and supported properly to maintain stability throughout the construction process. 6. Implementing Fall Protection: Adequate fall protection measures, such as guardrails or safety harnesses, should be in place when working at heights. Additionally, workers should exercise caution on slippery surfaces and take necessary precautions to prevent slips, trips, and falls. 7. Communicating Hazards: Clear signage and warnings should be prominently displayed to alert workers to potential hazards and provide instructions on safety procedures. Effective communication and coordination among workers are also essential in preventing accidents. 8. Regular Maintenance: Regular maintenance and cleaning of the steel formwork are crucial to remove debris, rust, or other materials that could compromise its integrity. This will contribute to its overall safety and longevity. By adhering to these common safety guidelines, the risk of accidents and injuries can be significantly reduced, ultimately creating a safer work environment for all individuals involved.

- Q: New building formwork support is all steel

- The shear wall formwork support combination device is composed of a shear wall formwork support assembly device, which is composed of a cross beam, a vertical beam, a positive angle, a negative angle, a top pull rod, a door card, and a wall screw arch fitting. [] with the thickness of the vertical beam forming 2.75mm cold-rolled steel plate, welded by the jacket, Easter, Liang Xin. The structure and properties of the same column template support vertical beam structure. The cross beam is composed of an outer casing, a beam core, a movable joint, an outer sleeve and a beam core which are provided with a rectangular hole which is used for adjusting the size of the through wall screw

- Q: Are there any specialized tools or equipment required for steel formwork?

- Yes, there are several specialized tools and equipment required for steel formwork. Some of the common tools include: 1. Formwork Clamps: These are used to secure the steel formwork panels together, ensuring stability and alignment. 2. Formwork Ties: These ties are used to hold the formwork panels in place and prevent them from moving during the pouring and curing of concrete. 3. Formwork Brackets: These brackets are used to support the formwork panels and distribute the load evenly. 4. Formwork Shuttering Magnets: These magnets are used to hold the formwork panels in place, providing a strong and secure connection. 5. Formwork Jacks: These jacks are used to adjust the height of the formwork panels, allowing for precise leveling and alignment. 6. Formwork Hangers: These hangers are used to suspend the formwork panels from overhead structures, providing additional support and stability. 7. Formwork Props: These props are used to support the formwork panels vertically, ensuring they remain in position during the concrete pouring process. 8. Formwork Vibrators: These vibrators are used to remove air bubbles and ensure proper compaction of the concrete within the formwork. It is important to use these specialized tools and equipment properly to ensure the structural integrity and quality of the steel formwork.

- Q: How does steel formwork handle different concrete testing procedures?

- The construction industry favors steel formwork because of its durability and versatility. When it comes to concrete testing, steel formwork proves highly capable and efficient. To begin with, steel formwork can withstand the pressure and weight exerted by concrete during various testing procedures. Regardless of whether it's a compression test, slump test, or any other form of concrete testing, the robustness of steel formwork guarantees it remains intact and does not deform under the load. In addition, steel formwork provides a smooth and even surface for concrete testing. This is crucial for obtaining accurate test results since any irregularities or inconsistencies in the formwork can impact the quality and integrity of the concrete sample being tested. Steel formwork is renowned for its precision, ensuring the concrete is poured and shaped precisely as required for each specific testing procedure. Furthermore, steel formwork is adaptable and easily modified to accommodate different concrete testing procedures. It can be adjusted or reconfigured to meet the specific requirements of various tests, such as creating different shapes, sizes, or depths for concrete samples. This flexibility allows for efficient and accurate testing, as the formwork can be customized according to the testing procedure being carried out. Moreover, steel formwork is reusable, providing cost-effectiveness and sustainability in concrete testing. Unlike other types of formwork that may need to be discarded after a single use, steel formwork can be dismantled, cleaned, and reused multiple times. This reduces overall expenses associated with concrete testing procedures and minimizes waste generation, making it an environmentally friendly option. In conclusion, steel formwork is well-suited for handling different concrete testing procedures due to its strength, precision, adaptability, and reusability. It offers a stable and consistent surface for accurate testing, ensuring reliable results. With its numerous advantages, steel formwork remains the preferred choice in the construction industry for various concrete testing requirements.

Send your message to us

Steel-frame formwork for corner

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords