Protection-Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

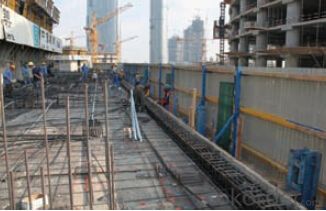

Protection Platform PP-50

A kind of new type construction protection system, applying operating platform and safer job

location for construction corps.

Characteristics:

◆ Easy and quick assembling.

◆ Lifted as a group, it is rapid and economic.

◆ Auto-climbing

◆ A safe and reliable anchor system

1. Composition

2. Assembly process of anchor system

(1) Embed V-climbing cone and anchor plate into the slab.

(2) Fix anchor shoe on the slab by tensile bolt.

(3) The fixed anchor shoe.

◆ High work efficiency with work platform and unload platform

◆ High light transmittance with the hollow block

- Q: How is steel formwork transported to the construction site?

- Depending on the distance, quantity, and accessibility of the construction site, steel formwork is transported using different methods. Truck transportation is a common choice for shorter distances and smaller quantities. This involves loading the steel formwork components onto a flatbed or trailer and driving them to the site. For larger quantities or longer distances, rail or sea transportation may be used. Rail transport is efficient for moving large quantities over long distances, especially when the site is far from the manufacturing facility. On the other hand, sea transport is ideal for international projects that require shipping the formwork overseas. The formwork is loaded into shipping containers and transported by cargo ships. Upon arrival at the construction site, cranes or forklifts are used to unload the steel formwork. The components are then stored in a designated area until they are ready for installation. It is crucial to carefully plan and execute the transportation process to prevent any damage to the formwork. Any issues with structural integrity can adversely affect the quality and safety of the final construction project.

- Q: How does steel formwork handle different concrete crack control measures?

- Steel formwork is a versatile and durable option for handling different concrete crack control measures. One of the main advantages of using steel formwork is its ability to provide a rigid structure that can effectively resist the forces exerted during the pouring and curing of concrete. This rigidity helps in minimizing the occurrence of cracks in the concrete. When it comes to crack control measures, steel formwork offers several advantages. Firstly, the smooth surface of steel formwork allows for easy placement and compaction of concrete, reducing the likelihood of voids and air pockets that can lead to cracking. Additionally, steel formwork can be designed to accommodate various reinforcing measures such as rebar and mesh, which further enhance crack control. Moreover, steel formwork allows for precise control over the curing process. By using steel forms, contractors can regulate the rate of concrete hydration, which is crucial for crack control. Proper curing techniques, such as the application of curing compounds or the use of thermal insulation, can be easily implemented with steel formwork, ensuring optimal conditions for crack prevention. In terms of crack repair, steel formwork provides an advantage by allowing for easy access to the concrete surface. In the event of cracks, repairs can be carried out by injecting epoxy or other suitable materials directly into the affected areas. The rigidity of steel formwork ensures that the repaired sections maintain their structural integrity and prevent further cracking. Overall, steel formwork is a reliable solution for handling different concrete crack control measures. Its rigidity, smooth surface, and compatibility with reinforcing measures make it highly effective in minimizing cracks during the pouring, curing, and repair stages of concrete construction.

- Q: How does steel formwork affect the overall construction site safety?

- Steel formwork can significantly enhance overall construction site safety. Its strength and durability ensure stability and structural integrity during concrete pouring and curing processes. The use of steel formwork reduces the risk of formwork collapse or failure, which can cause serious accidents and injuries. Additionally, steel formwork's fire-resistant properties provide an added layer of safety, minimizing the potential for fire-related incidents. Overall, steel formwork promotes a safer construction site by reducing potential hazards and enhancing the structural stability of the project.

- Q: Types of building templates? What is clear water template?

- Wood plywood (water templates): currently widely used in the solid wood plywood formwork, should promote the use of wood covered plywood. Commonly used in Guangdong area of Eucalyptus wood membrane.

- Q: Is steel formwork suitable for all types of construction projects?

- Steel formwork is a versatile and widely used construction material that is suitable for a variety of construction projects. However, it may not be suitable for all types of construction projects. Steel formwork offers several advantages such as durability, reusability, and high load-bearing capacity. It can be used for both large-scale and small-scale projects, including residential, commercial, industrial, and infrastructure projects. Steel formwork is particularly well-suited for projects that require a high degree of precision and quality finish, such as high-rise buildings, bridges, and tunnels. However, there are certain factors to consider when determining the suitability of steel formwork for a specific construction project. One important factor is the project's budget. Steel formwork tends to have a higher initial cost compared to other types of formwork materials such as timber or aluminum. Therefore, it may not be suitable for projects with tight budget constraints. Another factor to consider is the project's timeline. Steel formwork requires skilled labor and time for assembly, disassembly, and transportation. This may result in longer construction periods, which may not be feasible for projects with strict deadlines. The complexity of the project is also an important factor to consider. Steel formwork is highly adaptable and can be custom-made for specific project requirements. However, if the project involves irregular or complex shapes, it may be more challenging and time-consuming to construct steel formwork compared to other types of formwork materials. Additionally, the environmental conditions of the construction site should be taken into account. Steel formwork is durable and can withstand harsh weather conditions. However, it may not be suitable for projects in coastal areas or locations with high humidity, as steel is susceptible to corrosion. In conclusion, while steel formwork is suitable for a wide range of construction projects, its suitability should be evaluated on a case-by-case basis. Considerations such as budget, timeline, complexity of the project, and environmental conditions should be taken into account to determine if steel formwork is the most suitable choice for a specific construction project.

- Q: What are the different types of formwork bracing used in steel formwork?

- There are several different types of formwork bracing used in steel formwork, each providing unique features and benefits. Here are some of the most common types: 1. Adjustable Steel Bracing: This type of bracing consists of adjustable steel tubes or rods that can be easily extended or retracted to the desired length. It allows for quick and easy installation and adjustment, making it ideal for projects with varying formwork heights. 2. Cross Bracing: Cross bracing, as the name suggests, involves diagonal steel members that are placed to form an "X" shape between vertical supports. It provides lateral stability to the formwork system and helps prevent buckling or deformation. 3. Tie Rod Bracing: Tie rod bracing involves the use of threaded steel rods that are connected through formwork panels to provide additional strength and stability. It is commonly used in large-scale formwork systems where high loads need to be supported. 4. External Bracing: External bracing is often used in taller formwork structures to provide increased stability against wind forces. It involves installing steel members on the exterior side of the formwork system to resist lateral movement and maintain structural integrity. 5. Kickers: Kickers are diagonal bracing elements that are installed between formwork panels and the ground or a solid anchor point. They help transfer the lateral forces and prevent the formwork from tilting or collapsing. 6. Strut Bracing: Strut bracing involves the use of steel struts or props that are placed vertically between the formwork panels and the ground. It provides additional support to prevent horizontal movement and ensure the stability of the formwork system. 7. Flying Bracing: Flying bracing is used in situations where formwork needs to be supported from above, such as in bridge construction or overhead structures. It involves suspending bracing elements from overhead supports to provide stability and prevent formwork deformation. Each type of formwork bracing has its advantages and is chosen based on the specific requirements of the project, including the height and size of the formwork, expected loads, and site conditions. A combination of different bracing types may also be used to provide optimal stability and safety.

- Q: How does steel formwork handle different concrete curing temperatures?

- Steel formwork is highly resistant to different concrete curing temperatures. It can withstand both high and low temperatures without warping, distorting, or losing its structural integrity. This makes it a reliable choice for construction projects that require concrete curing in various temperature conditions.

- Q: What are the common safety certifications for steel formwork systems?

- The common safety certifications for steel formwork systems include ISO 9001:2015, OHSAS 18001, and EN 12811-1.

- Q: How does steel formwork affect the overall weight of the structure?

- Steel formwork can have a significant impact on the overall weight of a structure. Compared to traditional timber formwork, steel formwork is generally heavier due to the inherent properties of steel. Steel is denser and heavier than wood, which means that steel formwork will contribute more to the overall weight of the structure. However, the weight of the steel formwork can also be advantageous in certain situations. The increased weight of steel formwork can provide stability and rigidity to the structure during the construction process, ensuring that the concrete is properly supported and shaped. This can lead to a more precise and durable final structure. Moreover, steel formwork is typically more durable and can be reused multiple times, whereas timber formwork often needs to be replaced after a few uses. This can result in a reduced environmental impact and cost savings in the long run, even though steel formwork may initially add more weight to the structure. Ultimately, the effect of steel formwork on the overall weight of a structure depends on various factors such as the size and complexity of the project, the specific design requirements, and the construction method chosen. However, it is important to consider the trade-offs between the weight of the formwork and its benefits in terms of stability, durability, and cost-effectiveness.

- Q: What are the typical corrosion protection measures for steel formwork systems?

- To help prolong the lifespan and maintain the structural integrity of steel formwork systems, there are various typical measures for corrosion protection. One method that is commonly used involves applying protective coatings. These coatings, such as epoxy coatings, act as a barrier against moisture and corrosive elements. They are usually applied to the entire surface of the steel formwork system, including joints and connection points, to prevent direct contact between the steel and the surrounding environment. Another measure that can be taken is galvanizing. This process entails coating the steel formwork system with a layer of zinc, creating a protective barrier against corrosion. Galvanizing is particularly effective in environments with high moisture levels or exposure to saltwater, such as coastal areas. Regular maintenance is crucial for corrosion protection as well. It is important to regularly inspect the formwork system for any signs of damage or deterioration, such as rust or pitting. Any areas of concern should be promptly addressed through repair or replacement. Additionally, regular cleaning and removal of debris or contaminants can help prevent corrosion. Proper storage and handling of the steel formwork system is another significant measure. It is essential to store the formwork in a dry and well-ventilated area to minimize exposure to moisture. Moreover, it should be handled correctly to avoid unnecessary damage or scratches that could compromise the protective coatings. Lastly, sacrificial anodes can be utilized as a corrosion protection measure. These anodes, typically made from a metal more reactive than the steel formwork system, like zinc or magnesium, corrode in place of the steel, effectively sacrificing themselves to protect the system. In summary, employing a combination of protective coatings, galvanizing, regular maintenance, proper storage, and sacrificial anodes can ensure effective corrosion protection for steel formwork systems, guaranteeing their longevity and durability.

Send your message to us

Protection-Platform for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords