Adjustable Arced Steel Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

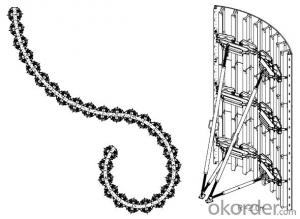

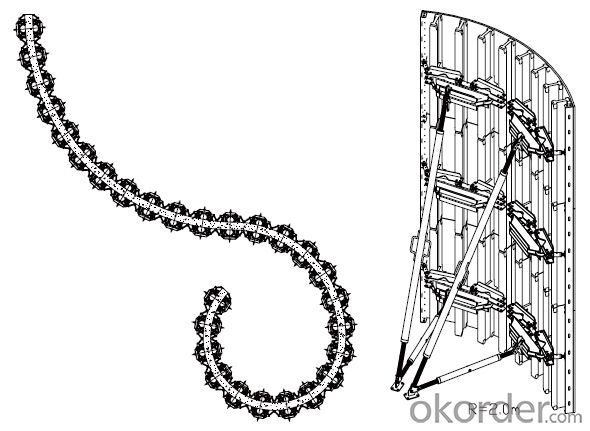

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q: How does steel formwork contribute to the overall construction process?

- Steel formwork is a crucial component in the construction process as it provides a sturdy and durable framework for pouring concrete. It ensures that the concrete is poured into the desired shape and size, allowing for the creation of accurate and precise structures. Steel formwork also helps speed up the construction process by providing a reusable and easily adjustable system, reducing labor and material costs. Additionally, it enhances the overall strength and stability of the structure, making it an essential element for the successful completion of construction projects.

- Q: How does steel formwork affect the overall acoustics of the building?

- The overall acoustics of a building can be greatly influenced by the use of steel formwork. Steel formwork, due to its dense and rigid nature, tends to reflect sound waves rather than absorb them. This reflection can result in increased noise levels and the creation of echoes within the building. The utilization of steel formwork can lead to a longer reverberation time, which is the duration it takes for sound to diminish by 60 decibels. This can result in poor speech clarity and reduced audio quality within the space. Moreover, the sound reflections from steel formwork can disrupt the natural acoustic properties of the room, potentially causing distortion and resonance problems. To tackle these challenges, it is possible to incorporate sound-absorbing materials on the interior surfaces of the building. This can help decrease the reflection and reverberation of sound waves, thereby enhancing the overall acoustics of the space. Possible options include the use of acoustic panels, insulation materials, and ceiling treatments that absorb and scatter sound. When determining the type of formwork to be used, it is crucial to consider the specific requirements of the building and its intended purpose. For spaces where excellent acoustics are essential, such as auditoriums, concert halls, or recording studios, alternative formwork materials that offer superior sound absorption properties might be preferred over steel formwork. However, in other applications where acoustics are less critical, steel formwork can still be utilized effectively by incorporating appropriate sound-absorbing measures. In conclusion, the selection of steel formwork can significantly impact the acoustics of a building. By carefully considering sound absorption and reflection properties, and by implementing additional acoustic treatments, it is possible to mitigate any negative effects and create a more pleasant and functional acoustic environment.

- Q: Can steel formwork be used for precast concrete slabs?

- Yes, steel formwork can be used for precast concrete slabs. Steel formwork provides a durable and strong solution for casting precast concrete slabs, ensuring accurate dimensions and a smooth finish.

- Q: How does steel formwork affect the overall long-term performance of the structure?

- Steel formwork can significantly enhance the long-term performance of a structure due to its durability, strength, and reusability. Compared to traditional wooden formwork, steel formwork offers superior resistance to moisture, rot, and warping, ensuring a longer lifespan for the structure. The rigidity of steel formwork also helps in maintaining the dimensional accuracy of the concrete elements, reducing the risk of cracks and deformations over time. Additionally, steel formwork's ability to withstand high pressures and loads enables it to support complex architectural designs and heavy concrete pours, resulting in a structurally sound and long-lasting construction.

- Q: Can steel formwork be used for both reinforced and non-reinforced concrete structures?

- Absolutely! Steel formwork is applicable to both reinforced and non-reinforced concrete structures. This flexible and long-lasting choice can endure the immense pressure generated by the concrete during pouring. Moreover, it can be effortlessly put together and taken apart, making it ideal for diverse construction undertakings. Whether it's a reinforced structure necessitating supplementary reinforcement bar support or a non-reinforced structure requiring a temporary mold, steel formwork proves effective in either scenario. Its robustness and steadiness enable the achievement of accurate shapes and measurements, guaranteeing the desired result for any concrete structure.

- Q: Can steel formwork be used for both monolithic and composite construction?

- Steel formwork is suitable for both monolithic and composite construction. In monolithic construction, concrete is poured continuously to form a solid structure, and steel formwork provides reliable support until the concrete sets and hardens. It is easy to assemble and disassemble, making it efficient for monolithic projects. Composite construction involves combining different materials for a stronger structure. Steel formwork can also be used in composite construction, particularly when concrete is combined with materials like steel beams or columns. The steel formwork acts as a mold, enabling the concrete to be poured and shaped around the other materials to create the desired structure. In summary, steel formwork is a versatile choice for construction projects, including monolithic and composite methods. Its strength, durability, and ease of use make it a popular option for contractors and builders in a wide range of projects.

- Q: What are the environmental considerations of using steel formwork?

- When considering the environmental impact of using steel formwork, several factors need to be taken into account. Firstly, the production of steel involves the extraction of iron ore, which can have negative environmental consequences. Mining activities can lead to deforestation, habitat destruction, and soil erosion. Additionally, the extraction process requires a significant amount of energy, often obtained from non-renewable sources, contributing to greenhouse gas emissions. Another environmental consideration is the transportation of steel formwork. Steel is a heavy material, and moving it from the manufacturing site to the construction site can result in increased fuel consumption and emissions. This is especially true in cases where the construction site is located far from the steel manufacturing facility. However, it is important to note that steel formwork can have several environmental advantages as well. Steel is a durable material that can be reused multiple times, reducing the need for new formwork production. This helps to minimize the demand for raw materials and reduces waste generation. Steel formwork can also be easily recycled at the end of its lifespan, further reducing the environmental impact. Moreover, steel formwork is known for its strength and stability, which can result in more efficient construction processes. This can lead to reduced construction time and lower energy consumption during the building phase. To mitigate the environmental impact of using steel formwork, it is important to prioritize sustainable practices throughout its lifecycle. This includes sourcing steel from responsible suppliers who prioritize environmental stewardship, promoting recycling and reuse of formwork, and optimizing transportation and logistics to reduce carbon emissions. Overall, while there are environmental considerations associated with using steel formwork, its durability, reusability, and recyclability make it a viable option for sustainable construction practices when managed responsibly.

- Q: What are the different types of steel formwork accessories available?

- In the market, one can find a variety of steel formwork accessories that serve different purposes. These accessories are specifically designed to improve the efficiency and effectiveness of steel formwork systems, thereby making the construction process smoother. Here are some commonly used types of steel formwork accessories: 1. Formwork clamps: These clamps are utilized to securely connect formwork panels, guaranteeing stability and preventing any movement while pouring concrete. They come in various sizes and shapes to fit different formwork systems. 2. Formwork ties: These ties are employed to hold formwork panels together and provide additional support. Formwork ties are available in different lengths and materials to meet various formwork requirements. 3. Formwork connectors: These connectors are used to join formwork panels at corners or intersections. They create a strong and secure connection, ensuring proper alignment and stability of the formwork system. 4. Formwork wedges: These wedges are used to adjust the inclination or angle of formwork panels. They are typically made of steel and can be easily inserted or removed to achieve the desired formwork configuration. 5. Formwork brackets: These brackets are utilized to vertically or horizontally support formwork panels. They are adjustable and can be easily installed or removed to accommodate different formwork configurations. 6. Formwork spacers: These spacers are used to maintain a specific spacing between formwork panels. They ensure consistent concrete thickness and prevent bulging or deformation during the pouring process. 7. Formwork props: These props are used to support the formwork system and provide additional stability. They can be adjusted in height and easily installed or removed as required. 8. Formwork anchors: These anchors are employed to secure the formwork system to the ground or existing structure. They provide stability and prevent any movement during the concrete pouring and curing process. Overall, these steel formwork accessories are crucial for ensuring the structural integrity and stability of the formwork system. They are designed to withstand high pressure and offer a reliable and efficient solution for construction projects.

- Q: How does steel formwork affect the cost of construction?

- Steel formwork can significantly impact the cost of construction in various ways. Firstly, steel formwork is durable and reusable, reducing the need for frequent replacements and ultimately lowering overall costs. Additionally, steel formwork allows for faster construction due to its ease of assembly and disassembly, leading to reduced labor and time expenses. Moreover, steel formwork provides superior strength and stability, which can reduce the need for additional structural support, resulting in cost savings. Finally, the flexibility of steel formwork enables it to be customized to different project requirements, optimizing material usage and minimizing waste, further impacting construction costs positively.

- Q: Can steel formwork be used for both flat and sloped surfaces?

- Yes, steel formwork can be used for both flat and sloped surfaces. Steel formwork is a versatile and durable option for construction projects and can be easily adapted to form structures with various slopes. The flexibility of steel allows it to be bent or shaped to the desired angle, making it suitable for creating formwork for sloped surfaces. Additionally, steel formwork provides excellent support and stability, ensuring that the concrete is poured accurately and evenly on both flat and sloped surfaces. Its strength and rigidity make it a reliable choice for constructing formwork systems that can withstand the pressures exerted by the concrete during the casting process, regardless of the surface slope.

Send your message to us

Adjustable Arced Steel Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords