410 Stainless Steel Sheet with Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

stainless steel of 410 sus

Specification

Item | stainless steel of 410 sus |

Standard | ASTM,AISI,JIS,EN,DIN,GB |

Surface | 2b |

Thickness | Cold rolled:0.3mm-3mm |

Width | 1000mm/1219mm/1250mm/1500mm or as customer’s requires. |

Length | As customer’s requirements. |

Edge | Slit/Mill Edge |

Origin | TISCO,LISCO,JISCO,BAOSTEEL,BAOXIN, Eastern Special Steel etc. |

MOQ | 2 Ton |

Payment Term | 30%T/T L/C at sight |

Price Term | FOB/CFR/CIF |

Delivery | 7-10 days after the deposit |

Packaging | Seaworthy Export Standard or as customer's requests. |

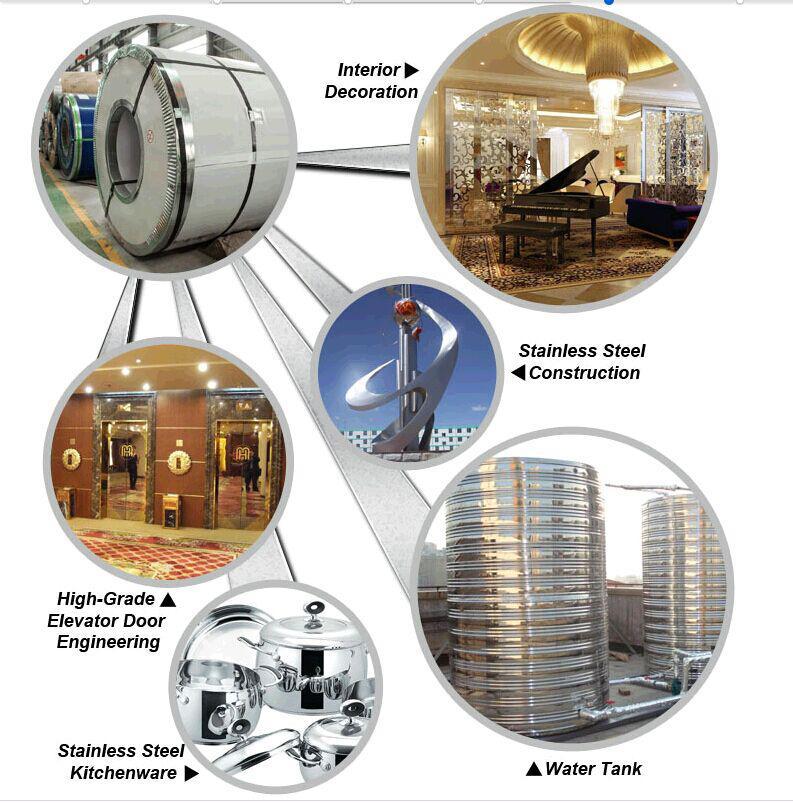

Application | construction field;ship building industry;petroleum and chemical industries;war and electricity industries;food processing and medical industry; boiler heat exchanger; machinery and hardware industry |

Length and width combination depends on thickness and grade. Minimum quantities may apply. Please contact us for exact dimension offer.

There are high-tech equipments to processing stainless coils and sheets/plates with skilled workers.

Cut to length

Decoiling and slitting

Grinding and brushing

Film protection

Plasma and water jet cutting

Folding and embossing

Architectual Moldings and Trim

Kitchen Equipment

Textile Paper

Pharmaceutical and

Chemical Industry Processing Euipment

Company Information

Our supplier produce a variety of products including bar, rod, wire, angles, plate, sheet and strip, in stainless steel ad other specialty steels.

We are specialized in this line for years.These are our cooperating countries :India, Bangladesh, USA, Vietnam, Iran, Ecuador, UAE, Algeria, Hungary etc.

Please rest assured that the quality and experience are ensured.

Main: 310 s, 316 l, 201, 202, 304, 304 l, 321, 316, 309 s such as thin, medium and thick plate, also according to the special needs of users, stainless steel order to undertake various special specifications of the stainless steel.

Certification

Our company has passed the SGS certification, and we have good reputation in the line of export of stainless steel.

Packaging & Shipping

| Packing details | 800 Ton/Tons per Day |

| Export standard package :bundled wooden box or be required | |

| Port:shanghai | |

| Delivery Time | 15 working days |

| Payment Terms | L/C ,T/T , western union , paypal , alipay |

| Shipping | DHL , UPS , FEDEX , TNT , EMS , by air , by sea , China post , any way you think is suitable |

eel plate

Our Services

stainless steel sheet

1.Professional person communicate with you before the order

2.OEM&ODM, also provide customized service

3.Offer for your unique design and some our current model

4.Protection of your sales area, ideas of design and all your private information

5.Provide strict quality check for each part,each process before export

6.Provide complete post-sale service,including installation,technical guide

Explore for more product information Leave an inquiry t know more details about price,packing,shipping and discount.

- Q: What is 3042B stainless steel?

- 304 is the material, 2B is cold rolling, 304 material used in corrosion resistance, strong oxidation resistance, containing 8% of nickel,

- Q: What is the average lifespan of stainless steel sheets?

- The lifespan of stainless steel sheets can vary depending on factors such as the grade and quality of the stainless steel, the environment in which it is used, and the level of maintenance and care it receives. In general, stainless steel sheets are renowned for their durability and long-lasting nature. They are specifically engineered to withstand corrosion, rust, and other forms of degradation, making them suitable for a wide array of applications. Under ideal conditions and with adequate maintenance, stainless steel sheets can endure for several decades or even longer. However, in harsher environments that expose them to aggressive chemicals, extreme temperatures, or high levels of moisture, their lifespan may be shortened. To ensure the longevity of stainless steel sheets, it is crucial to engage in regular cleaning, proper storage, and routine inspections. By adhering to recommended maintenance practices, stainless steel sheets can deliver reliable performance and endure for an extended period.

- Q: What specifications do stainless steel plates have?

- This is not specified. Do you want to make 201 or 304?. You can measure the size of the bag you want. Double fold (usually 10MM), such as length, width, and thickness of the package. Go and ask someone to do it for you. If fitted, use a glass or spot weld.

- Q: Are stainless steel sheets resistant to oxidation?

- Yes, stainless steel sheets are resistant to oxidation. Stainless steel contains a minimum of 10.5% chromium, which forms a protective layer of chromium oxide on the surface when exposed to oxygen. This layer acts as a barrier, preventing oxygen from reaching the underlying steel and thus inhibiting oxidation. This corrosion-resistant property of stainless steel makes it an ideal choice for various applications where exposure to moisture or harsh environments is a concern. Additionally, stainless steel sheets can also contain other alloying elements such as nickel, molybdenum, and titanium, which further enhance their resistance to oxidation and corrosion.

- Q: What are the different types of stainless steel sheet grades available?

- There are several different types of stainless steel sheet grades available, including 304, 316, 430, and 201. Each grade has its own unique properties and applications, making them suitable for various industries and purposes.

- Q: Are stainless steel sheets resistant to heat and high temperatures?

- Yes, stainless steel sheets are highly resistant to heat and high temperatures. Stainless steel is known for its excellent heat resistance properties, allowing it to maintain its strength and structural integrity even at extreme temperatures. This makes stainless steel sheets suitable for a wide range of applications where heat and high temperatures are involved, such as in industrial furnaces, boilers, heat exchangers, and automotive exhaust systems. Stainless steel can withstand temperatures up to 1200 degrees Celsius (2192 degrees Fahrenheit) without losing its structural properties, making it a popular choice in industries that require materials capable of withstanding intense heat. Additionally, stainless steel also exhibits good oxidation resistance, preventing the formation of rust or scale when exposed to high temperatures over prolonged periods. Overall, stainless steel sheets are an excellent choice for applications requiring resistance to heat and high temperatures.

- Q: What does stainless steel plate mean?

- The stainless steel plate is divided into two kinds of hot-rolled and cold-rolled parts according to the method of manufacture, including the thickness of 0.02-4 mm thin cold plate and 4.5-50 mm medium plate. According to the structural characteristics of steel, they can be divided into 5 types: austenite type, austenite ferrite type, ferrite type, martensite type and precipitation hardening type. Can withstand oxalic acid, sulfuric acid iron sulfate, nitrate, nitrate acid and hydrofluoric acid, sulfuric acid copper sulfate, phosphoric acid, formic acid and acetic acid and various acid corrosion, widely used in chemical, food, medicine, papermaking, petroleum, atomic energy industry, as well as construction, kitchen utensils, cutlery, household appliances, vehicles of all kinds of parts. In order to ensure the mechanical properties of various kinds of stainless steel sheet, such as yield strength, tensile strength, elongation and hardness, the steel plate must be annealed, treated by solution, aging treatment before delivery.

- Q: Can stainless steel sheets be used for electromagnetic compatibility?

- Yes, stainless steel sheets can be used for electromagnetic compatibility. Stainless steel is a highly conductive material that can effectively shield against electromagnetic interference (EMI) and radio frequency interference (RFI). It can be used to create enclosures or shielding to protect sensitive electronic devices from external electromagnetic fields.

- Q: Are stainless steel sheets available in different colors?

- Yes, stainless steel sheets are available in different colors.

- Q: Are stainless steel sheets suitable for aerospace applications?

- Yes, stainless steel sheets are commonly used in aerospace applications due to their excellent strength, corrosion resistance, and high-temperature capabilities. These sheets are suitable for various components such as aircraft bodies, engine parts, and structural elements, ensuring reliable performance and durability in demanding aerospace environments.

Send your message to us

410 Stainless Steel Sheet with Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords