Stainless Steel Plate 410 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

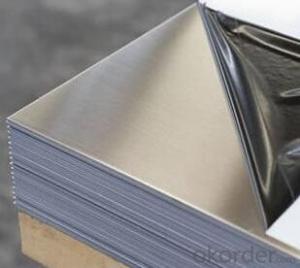

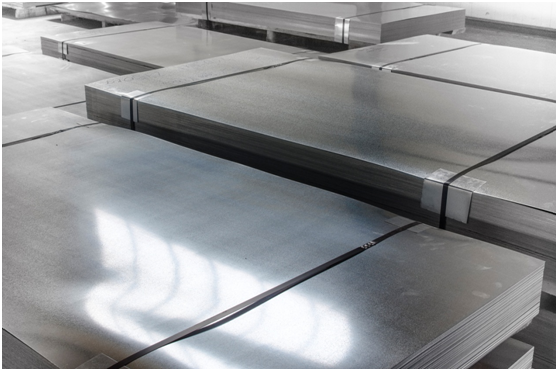

Stainless Steel Plate 410 with Surface Treatment

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

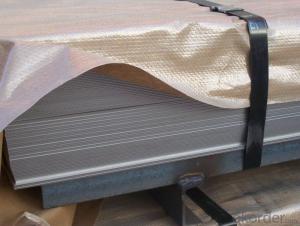

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

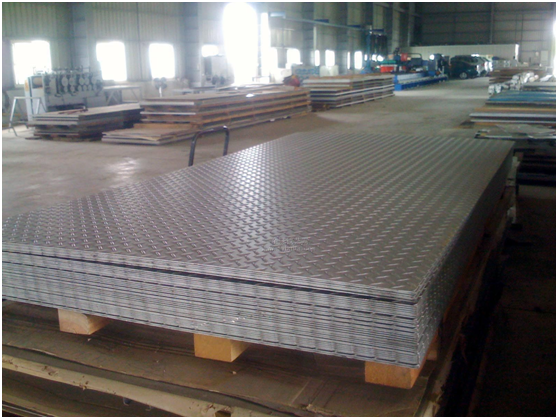

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

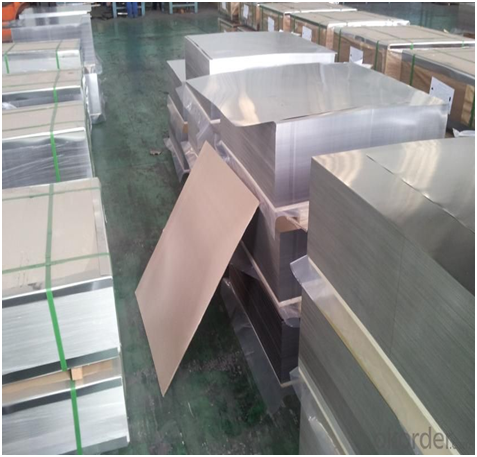

Product Details:

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets resistant to organic acids?

- Yes, stainless steel sheets are generally resistant to organic acids.

- Q: Are stainless steel sheets good for pressure piping?

- Yes, stainless steel sheets are good for pressure piping. Stainless steel is a strong and durable material that can withstand high pressure levels without deforming or breaking. It has excellent corrosion resistance properties, which makes it suitable for use in piping systems that carry fluids or gases under pressure. Stainless steel sheets are also easy to clean and maintain, making them a reliable choice for pressure piping applications in various industries such as oil and gas, chemical, and food processing.

- Q: What is the maximum size available for stainless steel sheets?

- The maximum size available for stainless steel sheets depends on several factors, including the manufacturing capabilities of the supplier and the specific requirements of the customer. Stainless steel sheets are typically available in standard sizes, which can vary depending on the thickness and grade of the stainless steel. In general, stainless steel sheets can be found in sizes ranging from 4 feet by 8 feet (1220mm x 2440mm) to larger sizes such as 5 feet by 10 feet (1524mm x 3048mm). However, it is also possible to find custom sizes or oversized sheets that exceed these dimensions, especially for industrial or specialized applications. It is important to note that larger sizes may come with additional challenges, such as increased weight and handling difficulties. Additionally, the availability of specific sizes may vary among suppliers, so it is recommended to consult with a stainless steel sheet supplier or manufacturer for the exact maximum size options they offer.

- Q: How do you polish stainless steel sheets?

- Achieving a polished look for stainless steel sheets can be accomplished by following a few straightforward steps. Begin by ensuring that the surface is immaculate and devoid of any dirt or debris. To eliminate any stains or marks, a mild detergent or stainless steel cleaner can be used. Next, utilize a soft cloth or sponge to apply either a stainless steel polish or a mixture of vinegar and olive oil. Apply the polish in the direction of the grain, which typically appears as a linear pattern on the stainless steel surface. Once the polish has been applied, utilize another clean cloth to buff the surface in the same direction as the grain. Apply gentle pressure and continue buffing until the stainless steel sheets start to exhibit a shining, polished appearance. If necessary, repeat the process in areas that require further polishing, ensuring that all excess polish is wiped away to prevent streaks or residue. It is crucial to consider that different stainless steel finishes may necessitate specific polishing techniques or products. For optimal results, always consult the manufacturer's instructions or guidelines.

- Q: What are the applications of stainless steel sheets in the automotive industry?

- Stainless steel sheets in the automotive industry are used for various applications such as body panels, exhaust systems, fuel tanks, and structural components. They provide excellent corrosion resistance, high strength, and durability, making them ideal for withstanding harsh conditions and ensuring long-lasting performance in vehicles. Additionally, stainless steel sheets can be easily formed and welded, allowing for precise shaping and customization according to the specific requirements of different automotive parts.

- Q: How do you cut stainless steel sheets?

- Stainless steel sheets can be cut using various methods, including manual cutting with tin snips or aviation snips, power tools such as angle grinders or shears, or specialized cutting techniques like plasma cutting or water jet cutting. The choice of method depends on the thickness of the stainless steel sheet, the precision required, and the available tools or equipment.

- Q: Are stainless steel sheets suitable for kitchen countertops?

- Kitchen countertops made from stainless steel sheets are highly suitable. They have numerous benefits that make them a popular choice. Firstly, stainless steel is incredibly durable and can withstand stains, heat, and scratches. This makes it perfect for the kitchen, where spills, hot pans, and knife marks are common. Moreover, stainless steel is non-porous, meaning it doesn't harbor bacteria or germs. This makes it an excellent choice for food preparation areas, as it ensures hygiene. Cleaning and maintaining stainless steel is also a breeze, as it doesn't require any special products or sealants. A simple wipe with a damp cloth is usually sufficient to keep it looking shiny and new. Additionally, stainless steel has a sleek and modern appearance that complements various kitchen styles and designs. It can be paired with different cabinetry colors and materials, creating a timeless and contemporary look. Stainless steel is also versatile, as it can be custom fabricated to fit any kitchen layout, including seamless integration with sinks and backsplashes. Lastly, stainless steel is an environmentally friendly option. It is a recyclable material, and many stainless steel products are made from recycled steel. This makes it a sustainable choice for those who want to minimize their environmental impact. In conclusion, stainless steel sheets are an excellent option for kitchen countertops due to their durability, resistance to stains and scratches, hygienic properties, easy maintenance, sleek appearance, and environmental friendliness.

- Q: What kind of screws do you choose for stainless steel plates?

- Because boards are often used for decoration, the best choice is not to be fixed with screwsJust use good glue, OKIf the plate is for other purposes, if the demand is not high, ordinary will do

- Q: How are stainless steel sheets used in the construction industry?

- Stainless steel sheets are commonly used in the construction industry for various applications. They are used to create durable and corrosion-resistant structures such as roofs, walls, and facades. Additionally, these sheets are often used to manufacture components like beams, columns, and frames due to their strength and versatility. Stainless steel sheets are also frequently employed for interior finishes and decorative purposes, as they provide a sleek and modern appearance. Overall, stainless steel sheets play a crucial role in construction, contributing to the longevity and aesthetic appeal of buildings.

- Q: What are the different types of stainless steel sheet finishes for industrial applications?

- There are several types of stainless steel sheet finishes for industrial applications, including 2B, No. 4, No. 8, BA, and brushed finishes.

Send your message to us

Stainless Steel Plate 410 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords