Stainless Steel Sheet/Plate 410 with Good Wear Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet/Plate 410 with Good Wear Resistance

Description of Stainless Steel Sheet/Plate 410 with Good Wear Resistance:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of Stainless Steel Sheet/Plate 410 with Good Wear Resistance:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Specifications of Stainless Steel Sheet/Plate 410 with Good Wear Resistance:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics Stainless Steel Sheet/Plate 410 with Good Wear Resistance:

| Surface finish | Characteristics and application |

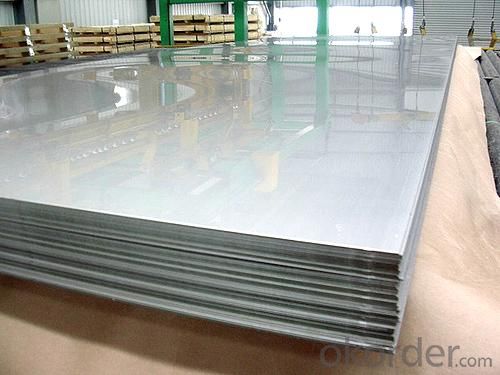

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

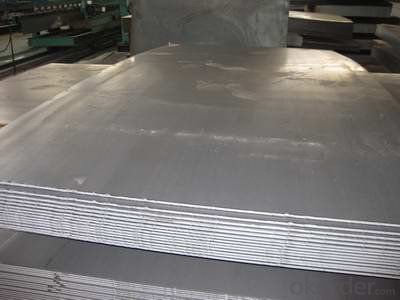

Images of Stainless Steel Sheet/Plate 410 with Good Wear Resistance:

Sandard Seaworth Packing of Stainless Steel Sheet/Plate 410 with Good Wear Resistance(wooden packing with water proof paper):

FAQ of Stainless Steel Sheet/Plate 410 with Good Wear Resistance:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be bent or formed into different shapes?

- Indeed, it is possible to bend or shape stainless steel sheets into various forms. This incredibly versatile material, stainless steel, can undergo a multitude of processes, including bending, rolling, and forming, enabling the creation of an extensive array of shapes and structures. The capacity to bend stainless steel sheets renders it highly suitable for implementation in industries such as architecture, automotive, and manufacturing. Furthermore, the exceptional corrosion resistance properties of stainless steel remain intact even after the bending procedure, further solidifying its status as a resilient and enduring material option for diverse applications.

- Q: Can stainless steel sheets be used for beer tanks?

- Indeed, beer tanks can utilize stainless steel sheets. The durability, corrosion resistance, and hygienic characteristics of stainless steel make it a prevalent material choice for beer tanks. To safeguard the quality of the beer and prevent contamination, stainless steel sheets are frequently employed in crafting the walls and inner surfaces of beer tanks. These sheets can be skillfully fabricated and welded together to form a seamless tank that can endure the pressure and temperature demands of the brewing procedure. Furthermore, stainless steel is effortlessly cleaned and maintained, rendering it an impeccable material for beer tanks.

- Q: Can stainless steel sheets be etched or engraved?

- Yes, stainless steel sheets can be etched or engraved. Etching and engraving are common methods used to create designs, patterns, and text on stainless steel surfaces. These techniques involve removing a thin layer of the metal to create the desired design. Etching can be done using chemicals or by using a laser, while engraving is typically done using a mechanical tool or laser. The etching or engraving process can create intricate and detailed designs on the stainless steel sheets, making them suitable for a wide range of applications such as signage, decorative panels, nameplates, and more.

- Q: Are stainless steel sheets resistant to scaling?

- Yes, stainless steel sheets are highly resistant to scaling. Due to their chromium content, they form a protective layer that prevents oxidation and scaling even at high temperatures.

- Q: Can stainless steel sheets be used for food preparation surfaces?

- Yes, stainless steel sheets can be used for food preparation surfaces. Stainless steel is a popular choice for food preparation surfaces due to its excellent properties. It is non-porous, which means it does not absorb any liquids or bacteria that can contaminate the food. Stainless steel is also resistant to corrosion, staining, and rusting, making it a durable and long-lasting option for food preparation surfaces. Additionally, stainless steel is easy to clean, as it can withstand high temperatures and is not affected by most cleaning agents. This makes it a hygienic choice for food preparation surfaces, as it can be thoroughly sanitized to prevent the growth of bacteria. Overall, stainless steel sheets are a safe and practical choice for food preparation surfaces.

- Q: Are stainless steel sheets suitable for architectural facades?

- Yes, stainless steel sheets are highly suitable for architectural facades. Stainless steel is a versatile and durable material that offers several advantages when used in architectural applications. One of the main reasons stainless steel sheets are suitable for facades is their aesthetic appeal. Stainless steel has a sleek and modern look that can enhance the overall appearance of a building. It can be finished in various ways, such as brushed, mirrored, or patterned, allowing architects to achieve the desired design aesthetic. In addition to its visual appeal, stainless steel is also highly resistant to corrosion. This makes it ideal for outdoor applications, as it can withstand exposure to harsh weather conditions, pollution, and other environmental factors without deteriorating. Stainless steel's corrosion resistance also means that it requires minimal maintenance, reducing long-term costs and efforts associated with facade upkeep. Another advantage of stainless steel sheets for architectural facades is their strength and durability. Stainless steel is a strong material that can withstand impact, making it suitable for high-traffic areas or buildings located in areas prone to severe weather events. It is also resistant to staining, scratching, and fading, ensuring that the facade remains attractive and intact for an extended period. Additionally, stainless steel is a sustainable material choice for architectural facades. It is 100% recyclable and can be reused without losing its properties, making it an environmentally friendly option. Stainless steel's longevity also contributes to sustainability, as it reduces the need for frequent replacements over time. Overall, stainless steel sheets are a highly suitable choice for architectural facades due to their aesthetic appeal, corrosion resistance, strength, durability, and sustainability. Whether used in modern or traditional designs, stainless steel can provide a long-lasting and visually pleasing solution for enhancing the exterior of buildings.

- Q: What is the thermal expansion rate of stainless steel sheets?

- The thermal expansion rate of stainless steel sheets varies depending on the specific grade of stainless steel and the temperature range in which it is exposed. Generally, stainless steel has a coefficient of thermal expansion (CTE) of around 10-17 x 10^-6 per degree Celsius (µm/m°C). This means that for every degree Celsius increase in temperature, the stainless steel sheet will expand by 10-17 micrometers per meter of length. It is important to note that the CTE can vary slightly for different grades of stainless steel, so it is recommended to consult the manufacturer's specifications or engineering handbooks for more precise information on the thermal expansion rate of a particular stainless steel sheet.

- Q: Can stainless steel sheets be used for oil and gas pipelines?

- Yes, stainless steel sheets can be used for oil and gas pipelines. Stainless steel is highly resistant to corrosion and can withstand extreme temperatures and pressures, making it a suitable material choice for these applications. Its durability and longevity make it an ideal option for oil and gas pipelines, ensuring a reliable and efficient transportation system.

- Q: What is stainless steel AB board, please?

- It should be said that BA (Bright, Annealing, bright annealing) plate, and 2B plate difference is that annealing process is different, 2B using annealing and pickling combination process, BA using hydrogen protection, annealing under anaerobic environment. The rolling process and leveling process of the two surfaces are also different.

- Q: Are stainless steel sheets scratch-resistant?

- Yes, stainless steel sheets are scratch-resistant due to their high durability and resistance to wear and tear.

Send your message to us

Stainless Steel Sheet/Plate 410 with Good Wear Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords