Stainless Steel Sheets Made in China 201 410 Material Sheet Stainless Steel Price

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Technical notes:

Surface Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

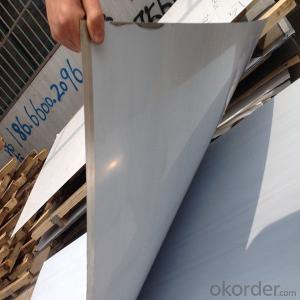

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

FAQ for Stainless Steel Coils/Sheets:

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: How are stainless steel sheets installed?

- Different methods are used to install stainless steel sheets depending on the specific application and requirements. Here are several common installation methods for stainless steel sheets: 1. Adhesive: A popular and straightforward method involves using a specialized adhesive to bond the stainless steel sheet to the desired surface. The adhesive is applied to the back of the sheet, which is then firmly pressed onto the surface. This method is suitable for flat or slightly curved surfaces and results in a seamless and clean installation. 2. Mechanical fasteners: When additional strength and stability are necessary, stainless steel sheets can be installed using mechanical fasteners like screws, bolts, or rivets. These fasteners are drilled or screwed through the sheet and into the surface to secure it. This method is often used for installations that require resistance to external forces or for attaching stainless steel sheets to structural components. 3. Welding: In some cases, particularly for large or complex installations, welding may be employed to connect stainless steel sheets together or to other metal structures. Welding creates a strong and permanent bond between the sheets, ensuring a secure installation. However, this method requires skilled professionals and specialized equipment to ensure proper welding techniques and prevent damage to the stainless steel. 4. Magnetic attachment: Certain stainless steel sheets are designed with a magnetic backing, allowing them to be easily attached to magnetic surfaces. This method offers quick and convenient installation as the sheets can be easily repositioned or removed if necessary. However, it is important to ensure that the magnetic surface is clean and free from debris that could affect the adhesion. Before installing stainless steel sheets, it is crucial to thoroughly clean the surface and remove any dirt, dust, or grease. This preparation will help ensure a secure and long-lasting installation. Additionally, following the manufacturer's instructions and guidelines specific to the stainless steel sheet being installed is essential for achieving the best results.

- Q: Are stainless steel sheets fire-resistant?

- Yes, stainless steel sheets are fire-resistant.

- Q: Can stainless steel sheets be used for elevator doors or panels?

- Yes, stainless steel sheets can be used for elevator doors or panels. Stainless steel is a popular choice for elevator applications due to its durability, corrosion resistance, and sleek appearance. It provides a clean and modern look, making it a suitable material for elevator doors or panels.

- Q: Can stainless steel sheets be used for conveyor belts?

- Certainly! Conveyor belts can utilize stainless steel sheets. Stainless steel, being highly durable and resistant to corrosion, is well-suited for diverse industrial uses, such as conveyor belts. These sheets possess the capability to endure high temperatures, heavy loads, and abrasive substances, making them perfect for conveying purposes. Moreover, the smooth surface of stainless steel facilitates the smooth movement of products and reduces friction, ensuring efficient and dependable conveyor operations.

- Q: What is the price range of stainless steel sheets?

- The price range of stainless steel sheets can vary depending on factors such as size, thickness, grade, and quantity. Generally, stainless steel sheets can range from around $20 to $200 per sheet.

- Q: Can stainless steel sheets be used for heat recovery systems?

- Yes, stainless steel sheets can be used for heat recovery systems. Stainless steel is known for its excellent heat resistance and durability, making it an ideal material choice for heat recovery applications. Its corrosion resistance and ability to withstand high temperatures make it suitable for capturing and transferring heat efficiently in various heat recovery systems.

- Q: What are the different types of stainless steel sheet alloys available?

- When choosing a stainless steel sheet alloy, it is crucial to take into account the particular needs of your application, as each alloy possesses its own set of advantages and disadvantages. There exists a variety of stainless steel sheet alloys from which to choose, each offering distinct properties and characteristics. Some of the most frequently encountered stainless steel sheet alloys are as follows: 1. Austenitic Stainless Steel: This is the most commonly used and versatile type of stainless steel. It lacks magnetic properties and contains substantial amounts of chromium and nickel, resulting in exceptional corrosion resistance and good formability. The 304 and 316 grades are examples of austenitic stainless steel alloys. 2. Ferritic Stainless Steel: Ferritic stainless steel possesses magnetic qualities and contains high chromium levels. It exhibits good corrosion resistance and is generally less expensive than austenitic stainless steel. The 430 and 446 grades are common examples of ferritic stainless steel alloys. 3. Martensitic Stainless Steel: Martensitic stainless steel is magnetic and contains significant amounts of carbon and chromium. It is renowned for its hardness and strength, rendering it suitable for applications requiring high wear resistance. The 410 and 420 grades are examples of martensitic stainless steel alloys. 4. Duplex Stainless Steel: Duplex stainless steel is a combination of austenitic and ferritic stainless steels, offering a balanced blend of their properties. It possesses increased strength and corrosion resistance when compared to austenitic stainless steel. Common duplex stainless steel alloys include the 2205 and 2507 grades. 5. Precipitation Hardening Stainless Steel: Precipitation hardening stainless steel alloys can be heat treated to attain high levels of strength. They contain elements such as copper, aluminum, or titanium, which form precipitates during heat treatment, leading to enhanced strength. The 17-4PH and 15-5PH grades are examples of precipitation hardening stainless steel alloys. Therefore, it is essential to carefully consider the specific requirements of your application when selecting a stainless steel sheet alloy, as each alloy possesses its own unique strengths and limitations.

- Q: Can stainless steel sheets be etched with designs?

- Yes, stainless steel sheets can be etched with designs.

- Q: Can stainless steel sheets be used in the medical industry?

- Stainless steel sheets have the capability of being utilized within the medical industry. This is because stainless steel is a favored material within the medical field due to its exceptional resistance against corrosion, its remarkable strength, and its ability to endure. It is commonly employed for a diverse array of purposes, encompassing medical instruments, surgical tools, dental equipment, implants, and medical machinery. Moreover, stainless steel sheets are uncomplicated to cleanse and sterilize, rendering them perfect for maintaining hygienic conditions within medical settings. Furthermore, stainless steel is biocompatible, signifying that it is harmonious with human tissues and does not elicit any unfavorable reactions, thereby making it a secure option for medical applications. All in all, stainless steel sheets are exceedingly appropriate for usage within the medical industry due to their myriad advantageous qualities.

- Q: Can stainless steel sheets be used for architectural canopies?

- Architectural canopies can indeed make use of stainless steel sheets. This versatile material offers numerous advantages in architectural applications, including canopies. To begin with, stainless steel possesses great durability and resistance to corrosion, making it ideal for outdoor installations. This ensures that the canopy will endure harsh weather conditions and maintain its appearance over time. Furthermore, stainless steel boasts a sleek and contemporary aesthetic which can enhance the overall design of the canopy. It can be polished to a mirror-like finish or brushed to create a distinctive texture, giving architects a range of options to achieve their desired look. In addition, stainless steel sheets are available in various thicknesses, allowing for customization based on the specific requirements of the canopy. This flexibility guarantees that the material can support the weight of the structure and any additional elements, such as lighting or signage. Moreover, stainless steel is an environmentally-friendly choice for architectural canopies as it is fully recyclable. This aligns with the increasing demand for sustainable construction materials and practices. To summarize, stainless steel sheets are a popular and suitable choice for architectural canopies due to their durability, aesthetic appeal, flexibility, and sustainability.

Send your message to us

Stainless Steel Sheets Made in China 201 410 Material Sheet Stainless Steel Price

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords