40x26mm 4v 20ma Silicon Wafer Solar Cell for 800w Solar Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

40X26MM 4V 20mA Solar Cell for 800W Solar Panel

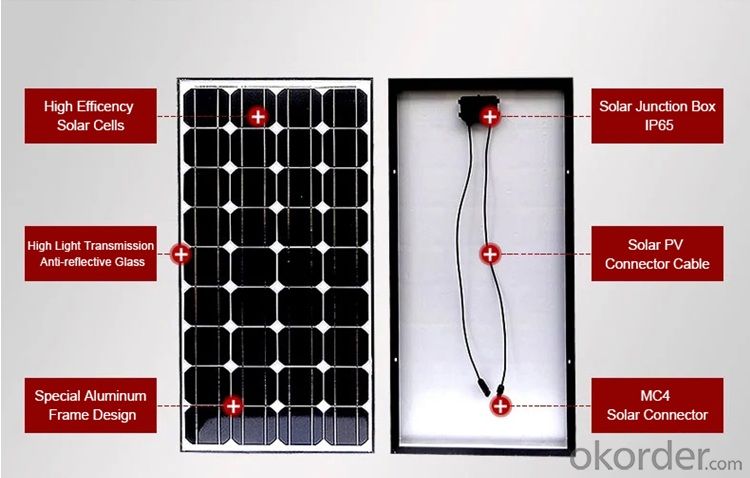

Solar Module Summarize

Solar Module is the core part of solar PV power systems,also is the highest value part of it. The function of Solor Module is to convert the sun's radiation to electrical energy, or transfer it to battery and store in it, or to drive the load running.

The Product has been widely used in space and ground, it mainly used for power generation systems, charging systems, road lighting and traffic signs areas. It could offer a wide range of power and voltage, and with high conversion efficiency, and long service life.

Our Cells Special Features

1. High conversion efficiencies resulting in superior power output performance

2.Outstanding power output even in low light or high temperature conditions

3.Optimized design for ease of soldering and lamination

4.Long-term stability,reliability and performance

5.For 156P poly cells with high efficiency in photovoltaic conversion 16.3%-17.5%.

6.Low inverse current, high shunt resistance and high dependability.

7. Our poly cells efficiency include: 17%-18%.

Product Pictures

Package

Typical package for one carton contains 1,200 cells. The cells are sealed in cell box every 100 pcs.

Gross weight per unit carton shall be around 16.4kg.

- Q: What is the role of surface texturing on solar silicon wafers?

- The role of surface texturing on solar silicon wafers is to enhance light trapping and increase the absorption of photons.

- Q: How are solar silicon wafers protected from moisture during storage?

- Solar silicon wafers are typically protected from moisture during storage by being sealed in airtight containers or packaging materials that have low moisture permeability. This prevents any moisture from coming in contact with the wafers, which could potentially degrade their performance or cause damage. Additionally, desiccant packets or moisture-absorbing materials are commonly used inside the packaging to further minimize moisture levels and maintain the integrity of the wafers.

- Q: How to detect the surface finish of photovoltaic silicon wafers, what equipment?

- Do you want to check the surface roughness or do you want to clean it? These two are not the same,

- Q: How is an encapsulant applied to a solar silicon wafer?

- An encapsulant is typically applied to a solar silicon wafer through a process called lamination. This involves placing the wafer between two layers of encapsulant material, such as EVA (ethylene-vinyl acetate), and then subjecting it to heat and pressure. The heat melts the encapsulant, enabling it to bond with the wafer, while the pressure ensures uniform distribution of the material and helps to remove any air bubbles. This lamination process provides protection to the solar silicon wafer from environmental factors and enhances its durability and performance.

- Q: What are the different materials used for encapsulants in solar silicon wafers?

- The different materials used for encapsulants in solar silicon wafers include ethylene-vinyl acetate (EVA), polyolefin-based materials, and thermoplastic polyurethane (TPU). These materials are used to provide protection, insulation, and adhesion for the silicon wafers, ensuring their durability and longevity in the harsh environmental conditions.

- Q: How does the efficiency of a solar silicon wafer change with temperature?

- The efficiency of a solar silicon wafer typically decreases with increasing temperature. This is because the electrical conductivity of silicon increases with temperature, leading to higher recombination rates and reduced electron-hole collection efficiency. Additionally, higher temperatures can cause an increase in the bandgap, resulting in a decrease in the number of photons absorbed by the wafer. These factors contribute to a decrease in the overall efficiency of the solar silicon wafer as temperature rises.

- Q: How are solar silicon wafers protected from lightning strikes?

- Solar silicon wafers are typically protected from lightning strikes through the installation of lightning arresters or surge protectors. These devices are connected to the solar panel system and act as a pathway for the lightning current to safely dissipate into the ground, thus preventing any damage to the silicon wafers.

- Q: What is the average reflectivity of a solar silicon wafer?

- The average reflectivity of a solar silicon wafer is typically around 30%.

- Q: Can solar silicon wafers be used in solar-powered security systems?

- Yes, solar silicon wafers can be used in solar-powered security systems. These wafers are commonly used to create solar panels that generate electricity from sunlight. By utilizing solar silicon wafers in solar-powered security systems, the systems can operate independently from the electrical grid, making them more versatile and efficient.

- Q: How is the demand for solar silicon wafers expected to grow in the future?

- The demand for solar silicon wafers is expected to grow significantly in the future. With the increasing global focus on renewable energy and the transition towards clean power sources, solar technology is poised for rapid expansion. This growth is driven by multiple factors, including decreasing costs of solar panels, government incentives and policies promoting solar energy adoption, and growing environmental concerns. As solar power becomes more affordable and efficient, the demand for silicon wafers, which are a crucial component in solar cells, is projected to increase to meet the rising demand for solar energy worldwide.

Send your message to us

40x26mm 4v 20ma Silicon Wafer Solar Cell for 800w Solar Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords