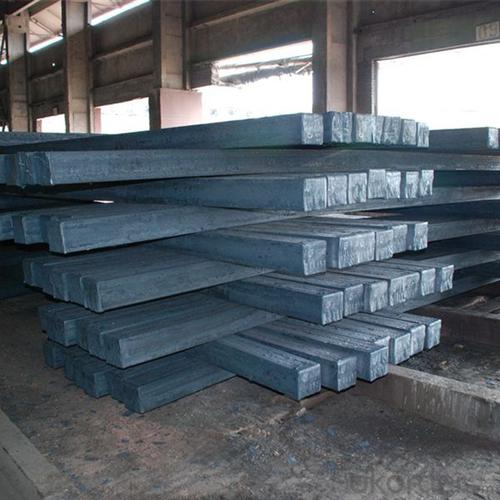

2016 High Quality Low Price Steel Billet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | 30*30-150*150 |

| Grade: | Q235,Q275 | Chemical Composition: | Hot Rolled Alloy Square Bar | Shape: | Square |

| Length: | 6m-12m | Standard: | ASTM | Technique: | Hot Rolled |

| Dimensions: | 100*100mm,130*130mm,150*150mm and etc | Alloy Or Not: | Is Alloy | Secondary Or Not: | Non-secondary |

| Product name: | 2016 High Quality Low Price Steel Billet |

Packaging & Delivery

| Packaging Details: | standard packing |

| Delivery Detail: | 7-30days |

FAQ

FAQ:

1.What's your MOQ?

25MT, it is for one container.

2.Are the products tested before shipping?

Yes, all of our products was qualified before shipping. We test every batch every day.

3.What's your normal delivery time?

Our delivery time about 7-30days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Do you send free sample?

Of cause.we send sample for free

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer

- Q: How are steel billets used in the manufacturing of power generation equipment?

- Steel billets are an essential raw material in the manufacturing of power generation equipment. These billets are large, rectangular or square-shaped semi-finished steel products that are cast from molten steel and then hot rolled or forged into their final shape. In the context of power generation equipment, steel billets are primarily used in the construction of turbine components, such as turbine blades and rotors, as well as in the fabrication of generator casings and other structural parts. The high strength and durability of steel make it an ideal material for these critical components, as they need to withstand high temperatures, pressure, and rotational forces. The process begins with the selection of an appropriate grade of steel billet, which depends on the specific requirements of the power generation equipment. The billets are then heated to a suitable temperature and forged or hot rolled to shape them into the desired form. This process involves precise machining, cutting, and shaping techniques to achieve the required dimensions and surface finish. Once the turbine components and other parts are formed from the steel billets, they undergo further treatments such as heat treatment, surface coating, and machining to enhance their mechanical properties and ensure their compatibility with the power generation system. The final products are then assembled into the power generation equipment, which may include gas turbines, steam turbines, wind turbine components, or generator sets. Steel billets play a crucial role in the manufacturing of power generation equipment by providing the necessary strength, durability, and performance required for efficient and reliable operation. The quality and precision in the production of steel billets directly impact the overall performance and longevity of the power generation equipment, making them a vital component in the industry.

- Q: What is the difference between hot-rolled and cold-rolled steel billets?

- Hot-rolled steel billets and cold-rolled steel billets are two types of steel that undergo different manufacturing processes, resulting in distinct characteristics and properties. When producing hot-rolled steel billets, the steel is heated to a high temperature and then rolled while still hot. This process allows for easy shaping and forming into various sizes and shapes. Additionally, hot-rolling creates a rough surface finish and a scaled outer layer due to exposure to high temperatures. Generally, hot-rolled steel billets have a larger grain structure, which can result in a less precise and uniform final product. However, they also possess improved mechanical properties, such as higher strength and toughness, making them suitable for applications where strength is important, but surface finish is not a priority. In contrast, cold-rolled steel billets are produced by cooling the steel to a low temperature and rolling it at room temperature. This process allows for tighter dimensional tolerances and a smoother surface finish compared to hot-rolled steel billets. Additionally, cold-rolling results in a more refined grain structure, which enhances the overall strength, hardness, and durability of the steel. Cold-rolled steel billets are commonly used in applications where precise dimensions, surface finish, and uniformity are required, such as in the automotive, construction, and appliance industries. To summarize, the main difference between hot-rolled and cold-rolled steel billets lies in the manufacturing processes and resulting properties. Hot-rolled steel billets are formed at high temperatures, resulting in a rough surface finish and larger grain structure. Cold-rolled steel billets, on the other hand, are formed at room temperature, leading to tighter dimensional tolerances, a smoother surface finish, and a more refined grain structure. The choice between hot-rolled and cold-rolled steel billets depends on specific requirements and applications, with hot-rolled steel billets being preferred for their superior strength and cold-rolled steel billets for their precise dimensions and surface finish.

- Q: Use medium frequency furnace (1 million 500 thousand volt ampere) to produce 1 ton cast steel blank, how much kilowatt hour is consumed?

- This depends on the intermediate frequency furnace voltage level and inverter efficiency, the general high voltage will save power, generally 550-700 range, details can refer to wcdlsb site medium frequency furnace data

- Q: What are the different methods of steel billet surface treatment?

- There are several methods of steel billet surface treatment that are commonly used in the industry. These methods aim to enhance the surface properties of the steel billets, such as improving corrosion resistance, increasing hardness, and improving aesthetics. Some of the most common methods of steel billet surface treatment are: 1. Pickling and Passivation: This process involves the removal of impurities and oxide layers from the steel surface using acid solutions. After pickling, the steel is passivated to create a protective layer that prevents future corrosion. 2. Shot Blasting: Shot blasting is a mechanical surface treatment method that involves the use of high-speed steel shots or grits to bombard the surface of the billets. This process removes scale, rust, and other contaminants, resulting in a clean and uniform surface. 3. Hot-Dip Galvanizing: In this process, the steel billets are immersed in a bath of molten zinc, which forms a protective coating on the surface. This method provides excellent corrosion protection, making it suitable for outdoor applications. 4. Electroplating: Electroplating involves the deposition of a thin layer of metal, such as chrome or nickel, onto the steel surface using an electric current. This method improves the appearance of the steel, enhances corrosion resistance, and can also provide better wear resistance. 5. Powder Coating: Powder coating is a popular method of surface treatment, especially for aesthetic purposes. It involves applying a dry powder onto the steel surface and then curing it through heat, resulting in a durable and attractive finish. 6. Painting: Painting is another common method used for surface treatment. The steel surface is first cleaned and primed before applying a suitable paint system. This method not only enhances the appearance but also provides protection against corrosion and environmental factors. 7. Nitriding: Nitriding is a heat treatment process that involves the diffusion of nitrogen into the steel surface. This method improves the hardness, wear resistance, and fatigue strength of the billets. These are just a few of the various methods of steel billet surface treatment available. The choice of method depends on the specific requirements of the application, desired properties, and budget considerations.

- Q: What are the main challenges in sourcing steel billets?

- The main challenges in sourcing steel billets include fluctuating prices, ensuring quality standards, finding reliable suppliers, dealing with logistics and transportation, and managing the risks associated with international trade and political instability in some steel-producing regions.

- Q: How are steel billets used in the production of shafts?

- Steel billets are an essential component in the production of shafts. A billet is a semi-finished product that serves as the starting point for various manufacturing processes. In the case of shaft production, steel billets are used as the raw material from which the shafts are formed. The process begins by heating the steel billets to a specific temperature, typically in a furnace. This heating process, known as "hot working," is crucial as it makes the steel more malleable and easier to shape. Once the billet reaches the desired temperature, it is then transferred to a forging press or a rolling mill. In the forging process, the heated billet is subjected to high pressure and shaped using specialized dies to achieve the desired shaft dimensions. This method allows for precise control over the shape, size, and surface finish of the shaft. On the other hand, in the rolling process, the billet is passed through a series of rollers that gradually shape it into a cylindrical form. Rolling is often used for shafts that require a constant cross-section along their length. After the initial shaping process, the shafts undergo further steps such as heat treatment, machining, and finishing to meet the specific requirements of their intended application. Heat treatment helps enhance the mechanical properties of the shaft, making it stronger, more durable, and resistant to wear. Machining processes, such as turning, milling, or grinding, are then carried out to achieve precise dimensions, smooth surfaces, and accurate tolerances. Overall, steel billets play a crucial role in the production of shafts as they provide a starting point for the shaping processes necessary to create these critical components. Through careful manipulation and refinement, steel billets transform into high-quality shafts that are used in various industries, including automotive, aerospace, manufacturing, and many others.

- Q: What are the different types of casting processes used for shaping steel billets?

- There are several different types of casting processes used for shaping steel billets. These processes include: 1. Continuous Casting: This is the most commonly used method for casting steel billets. In this process, molten steel is poured into a water-cooled mold that is continuously moving. As the steel solidifies, it is continuously pulled out of the mold, resulting in a continuous billet. This process is efficient and allows for high production rates. 2. Centrifugal Casting: In this process, molten steel is poured into a rotating mold. The centrifugal force generated by the rotation distributes the molten metal evenly along the mold walls, resulting in a cylindrical billet. This method is used to produce high-quality and defect-free billets. 3. Ingot Casting: This is a traditional method of casting steel billets. In this process, molten steel is poured into a mold and allowed to solidify. The solidified steel, known as an ingot, is then removed from the mold and further processed to obtain the desired shape of the billet. Ingot casting allows for flexibility in terms of billet shape and size. 4. Sand Casting: This process is used for producing large and complex steel billets. It involves creating a mold using a mixture of sand and a binder material. Molten steel is then poured into the mold, and once it solidifies, the mold is removed to reveal the billet. Sand casting allows for the production of custom-shaped billets but is a slower and less precise process compared to others. 5. Investment Casting: Also known as lost-wax casting, this process is suitable for complex and intricate shapes. In investment casting, a wax pattern of the desired billet shape is created. The wax pattern is then coated with a ceramic shell, and the wax is melted out, leaving behind a hollow mold. Molten steel is poured into the mold, and once it solidifies, the ceramic shell is broken to retrieve the billet. Each of these casting processes has its advantages and disadvantages, and the choice of process depends on factors such as the desired billet shape, size, production volume, and quality requirements.

- Q: What are the different surface finishes available for steel billets?

- There are several surface finishes available for steel billets, including mill finish, hot rolled pickled and oiled (HRPO), cold rolled, galvanized, and coated finishes. These finishes enhance the appearance, protect against corrosion, improve surface smoothness, and provide specific properties required for different applications.

- Q: What is the purpose of steel billets?

- Steel billets have a vital role in the steel manufacturing industry, as they act as the primary material for producing a range of steel products. These billets are semi-finished goods that usually have a square or rectangular shape, and they are created through the casting or hot rolling process. Once formed, these billets undergo further processing, including forging, rolling, or extrusion, to manufacture finished steel products such as bars, rods, wire, pipes, and tubes. The significance of steel billets lies in their ability to provide a consistent and uniform starting material that can be easily molded and shaped into various products. With desirable qualities like strength, durability, and ductility, these billets are well-suited for applications in construction, automotive, infrastructure, machinery, and many other industries. By utilizing steel billets, manufacturers can efficiently produce steel products with precise dimensions, mechanical properties, and surface finishes. By controlling the composition and processing techniques of the billets, steel manufacturers can customize the final product to meet specific customer requirements, ensuring optimal performance and quality. In conclusion, steel billets serve as the foundation for manufacturing various steel products. They play a crucial role in shaping and forming steel into the desired finished products, enabling industries to effectively meet the diverse needs of modern society.

- Q: What are the different finishing processes used for steel billets?

- There are several different finishing processes used for steel billets, including hot rolling, cold rolling, forging, and heat treatment. Hot rolling involves passing the billets through a series of rollers at high temperatures to achieve the desired shape and size. Cold rolling, on the other hand, involves passing the billets through rollers at room temperature to improve surface finish and dimensional accuracy. Forging involves shaping the billets by applying compressive force and heat, while heat treatment involves subjecting the billets to controlled heating and cooling processes to enhance their mechanical properties. These finishing processes are essential in producing high-quality steel billets for various applications.

Send your message to us

2016 High Quality Low Price Steel Billet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords