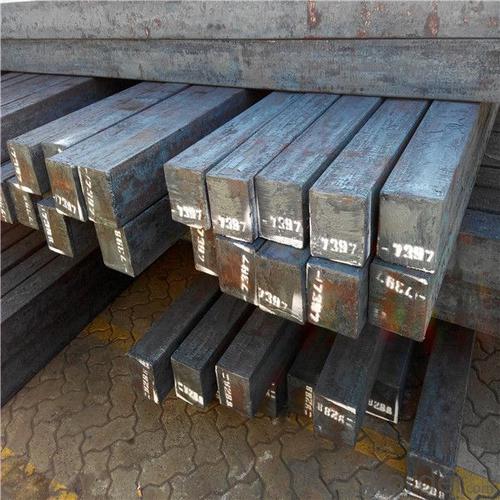

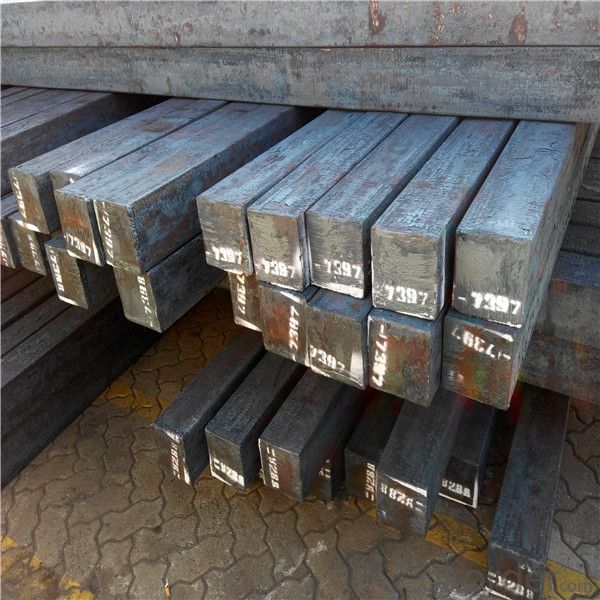

Steel Billet Low Price in high quality hot sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

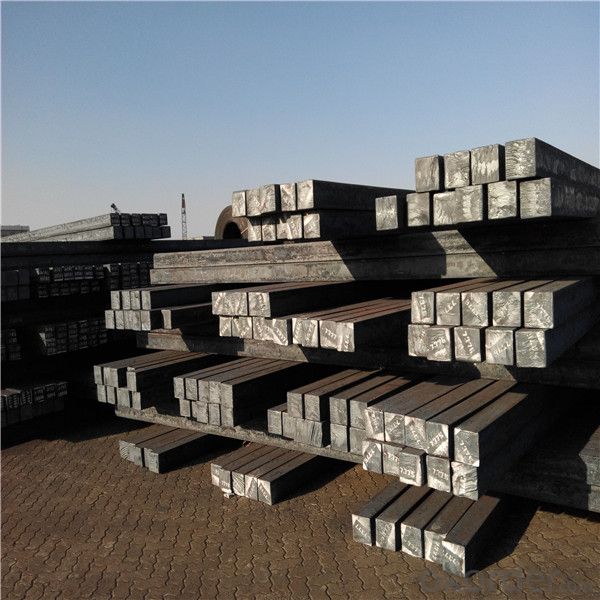

- Supply Capability:

- 15200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets

have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also

known for their malleability and ductility, especially when exposed to varying temperatures during shaping and

molding.

Used for the plant, the bridge,shipment building high rise building construction,lifting and transportation machinery, equipment manufracturing base building

the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still require

a series of shaping and molding procedures such as hot and cold working, milling and cutting before they

are sold in hardware stores, or used for different applications. The unformed billets, however, can be used

in striking currency such as coins and as reserves, similar to gold bars.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: Can steel billets be used for making architectural components?

- Yes, steel billets can be used for making architectural components. Steel billets are the raw material from which various steel products are formed, including architectural components such as beams, columns, and structural elements. The billets can be further processed through rolling, forging, or other techniques to create the desired shape and dimensions for architectural applications.

- Q: How do steel billets contribute to the overall fire resistance of a structure?

- Steel billets do not directly contribute to the fire resistance of a structure. However, steel is a fire-resistant material and when used in the construction of a building, it can enhance the overall fire resistance by providing structural integrity and stability even at high temperatures.

- Q: How do steel billets contribute to the manufacturing of defense equipment?

- Steel billets play a crucial role in the manufacturing of defense equipment. These billets are essentially semi-finished steel products that are used as raw materials in various manufacturing processes. Defense equipment requires materials that are strong, durable, and can withstand extreme conditions. Steel billets meet these requirements perfectly. One of the primary uses of steel billets in defense manufacturing is in the production of armored vehicles and tanks. These vehicles need to be highly resistant to ballistic threats and provide protection to the soldiers inside. Steel billets, with their exceptional strength and toughness, are an ideal choice for manufacturing the armor plates used in these vehicles. The billets are transformed into thick, hardened steel plates that provide excellent ballistic resistance and can withstand high-velocity impacts. Additionally, steel billets are used in the production of weaponry, such as firearms and missiles. These weapons require materials that can withstand the intense pressure and heat generated during firing or launching. Steel billets, with their high tensile strength and heat resistance, provide the necessary foundation for creating barrels, chambers, and other critical components of these weapons. Moreover, steel billets contribute to the manufacturing of defense equipment by being used in the production of various support structures and infrastructure. This includes military facilities, such as hangars, barracks, and storage facilities, which need to be robust and secure. Steel billets are transformed into beams, columns, and other structural elements that provide strength and stability to these buildings. In summary, steel billets are an essential component in the manufacturing of defense equipment. Their strength, durability, and ability to withstand extreme conditions make them ideal for producing armored vehicles, weaponry, and support structures. By utilizing steel billets, defense manufacturers can ensure the production of high-quality and reliable equipment that meets the stringent requirements of the defense sector.

- Q: What are the common alloys used in the production of steel billets?

- The common alloys used in the production of steel billets are primarily carbon and manganese. Carbon is added to increase the hardness and strength of the steel, while manganese is added to improve the steel's toughness and hardenability. Additionally, other alloying elements such as silicon, nickel, chromium, and vanadium may be added in smaller amounts to further enhance specific properties of the steel, such as corrosion resistance, heat resistance, or wear resistance. These alloying elements help create a wide range of steel grades with varying characteristics that can be tailored to suit different applications and industries.

- Q: What is the weight of a standard steel billet?

- The weight of a standard steel billet can vary depending on its dimensions and specific alloy composition. However, on average, a standard steel billet weighs around 1,000 to 1,500 kilograms or 2,204 to 3,307 pounds. It is important to note that different industries and regions may have their own standard sizes and weight ranges for steel billets.

- Q: How are steel billets used in the production of forged parts?

- Steel billets are an essential component in the production of forged parts. They serve as the starting material from which the desired shape and size of the forged part is created. To begin the process, steel billets are heated to a specific temperature to make them more malleable. This temperature, known as forging temperature, allows the steel to be easily deformed without cracking or breaking. Heating the billets also improves their structural integrity and makes them more resistant to deformation during the forging process. Once the steel billets reach the desired temperature, they are placed onto a forging press or hammer. The press applies immense pressure to the billets, forcing them to take the shape of the die or mold in which they are placed. This process is known as forging and it allows for the creation of complex shapes and intricate details that cannot be achieved through other manufacturing methods. The forged parts produced from steel billets are known for their exceptional strength, durability, and resistance to wear and tear. They are widely used in various industries, including automotive, aerospace, oil and gas, and construction. Forged parts can range from small components like gears and bolts to larger items such as crankshafts, connecting rods, and turbine blades. In summary, steel billets are used in the production of forged parts by providing the raw material that is shaped and formed through the forging process. The resulting forged parts possess superior mechanical properties and are vital components in many industrial applications.

- Q: What is the purpose of using steel billets in manufacturing?

- The purpose of using steel billets in manufacturing is to provide a raw material that can be further processed and shaped into various steel products, such as bars, rods, pipes, and structural components. Steel billets serve as a starting point for the manufacturing process, allowing for efficient and precise production of finished steel products.

- Q: What industries rely heavily on steel billets?

- Steel billets are an essential raw material for numerous industries, with construction being one of them. The construction industry relies on steel billets to fabricate structural components like beams, columns, and reinforcement bars, which are crucial for constructing buildings, bridges, and infrastructure projects. The strength and durability provided by steel billets are necessary for these construction applications. Another industry heavily dependent on steel billets is the automotive industry. They are used to manufacture different automotive parts, including engine components, chassis, and suspension systems. Steel billets are ideal for producing parts that can endure rigorous conditions and ensure vehicle safety due to their high strength and versatility. The oil and gas industry is also heavily reliant on steel billets for the production of pipelines, drill pipes, and other equipment used in exploration, extraction, and transportation processes. Steel billets are preferred in this industry for their corrosion resistance, high pressure resistance, and ability to withstand extreme temperatures. Furthermore, the machinery and equipment manufacturing industry extensively utilizes steel billets as the primary material for producing a wide range of machinery, including industrial machinery, agricultural equipment, and heavy-duty machinery. Steel billets provide the necessary strength, toughness, and machinability required for these applications. Moreover, the aerospace industry heavily depends on steel billets for manufacturing various aircraft components like landing gear, structural frames, and engine parts. Steel billets are chosen for their high strength-to-weight ratio, heat resistance, and ability to withstand the demanding conditions of aerospace applications. In conclusion, steel billets are indispensable in various industries such as construction, automotive, oil and gas, machinery and equipment manufacturing, and aerospace. Their unique properties ensure the production of strong, durable, and reliable products, making them vital for these industries.

- Q: What are the potential applications of steel billets in the telecommunications industry?

- Steel billets can be used in the telecommunications industry for various applications such as tower construction, antenna support systems, and cable management. The strength and durability of steel make it an ideal material for these purposes, ensuring the stability and longevity of telecommunications structures. Additionally, steel billets can be used for manufacturing equipment and components like brackets, frames, and enclosures, providing protection and support for sensitive telecommunications devices.

- Q: How do steel billets contribute to the automotive industry?

- Steel billets play a crucial role in the automotive industry as they are the raw materials used to manufacture various components such as engine blocks, transmission gears, axles, and chassis. These billets are forged and shaped into specific parts, providing the required strength, durability, and performance characteristics needed for automobiles. Additionally, steel billets offer excellent resistance to corrosion and high temperatures, ensuring the safety and reliability of vehicles on the road.

Send your message to us

Steel Billet Low Price in high quality hot sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords