Steel Billet high quality hot rolled in Best Price

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15921 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

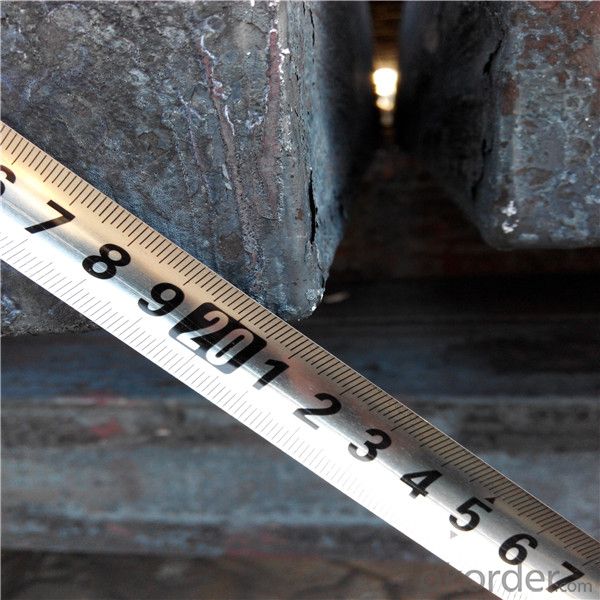

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets

have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also

known for their malleability and ductility, especially when exposed to varying temperatures during shaping and

molding.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Other Specifications

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How are steel billets manipulated during the manufacturing process?

- Steel billets are manipulated during the manufacturing process through various methods such as heating, rolling, forging, and cutting. Heating the billets makes them more malleable and easier to shape. Rolling involves passing the heated billets through a series of rollers to reduce their thickness and create desired shapes. Forging is another technique where the billets are shaped using compressive forces. Finally, cutting is done to obtain specific lengths or shapes required for further processing or fabrication.

- Q: The form of carbon in carbon steels

- There are three solid solutions of carbon in iron: alpha solid solution (Tie Suti), gamma solid solution (austenite) and delta solid solution (8 ferrite). The spatial distribution of iron atoms in these solid solutions is consistent with that of alpha -Fe, gamma -Fe and delta -Fe. The size of carbon atoms is much smaller than that of iron atoms.

- Q: How are steel billets used in the production of machinery and equipment?

- Steel billets are an essential component in the production of machinery and equipment. These billets serve as the raw material from which various parts and components are formed. The manufacturing process begins with the selection of high-quality steel billets, which are then heated and shaped using various techniques like hot rolling, forging, or extrusion. One common application of steel billets is in the production of machine parts such as gears, shafts, and axles. These billets are heated to a specific temperature, allowing them to be easily manipulated and formed into the desired shape. Once shaped, these parts undergo further processing such as heat treatment or machining to enhance their strength, durability, and precision. Steel billets are also used in the manufacturing of heavy machinery and equipment. For instance, in the construction industry, steel billets serve as the foundation for the production of cranes, excavators, and bulldozers. These billets are molded and shaped into various structural components, providing the necessary strength and stability required for such equipment to perform heavy-duty tasks. Moreover, steel billets find application in the production of industrial machinery, such as turbines, compressors, and pumps. These billets are transformed into intricate parts that possess high strength, corrosion resistance, and the ability to withstand extreme operating conditions. The properties of steel, such as its high strength, durability, and versatility, make it an ideal material for the production of machinery and equipment. Steel billets serve as the starting point for the manufacturing process, allowing manufacturers to create complex and reliable components that are crucial for the functioning of machinery and equipment in various industries.

- Q: What is the difference between steel and billet in the process?

- My understanding is that..:Billet: Billet, refers to the casting of roughSquare steel: Square, Bar, the product is rolled on the basis of square billet.

- Q: How are steel billets used in the manufacturing of consumer goods?

- Steel billets are an essential component in the manufacturing of various consumer goods. These billets are semi-finished steel products that are typically hot-rolled into various shapes, such as bars, rods, or sheets before they are used in the production process. One way steel billets are used in the manufacturing of consumer goods is in the production of automobiles. They are often transformed into different parts of a car's body, such as doors, fenders, or hoods. The strength and durability of steel make it an ideal material for these components, ensuring the safety and longevity of the vehicle. Another significant application of steel billets is in the construction industry. They are commonly used to produce beams, columns, and other structural elements that are crucial for building infrastructure like bridges, buildings, and stadiums. Steel's high tensile strength and ability to withstand heavy loads make it an ideal material for these applications. Steel billets also play a vital role in the manufacturing of appliances and household goods. For instance, they are used to produce refrigerators, washing machines, and ovens, where steel's resistance to corrosion and heat is highly valued. Additionally, steel billets are utilized in the production of furniture, tools, and kitchenware, providing strength and stability to these consumer goods. In the production of consumer goods, steel billets are typically subjected to various processes such as cutting, welding, and shaping to achieve the desired final product. These billets serve as the raw material that undergoes further manufacturing steps, including machining, forging, or casting, to create the specific components or parts needed. Overall, steel billets are an integral part of the manufacturing process for a wide range of consumer goods. The versatility, strength, and durability of steel make it a preferred material in industries such as automotive, construction, appliances, and furniture.

- Q: How are steel billets used in the production of construction components?

- Steel billets are an essential raw material in the production of construction components. They are primarily used in the manufacturing of various structural elements such as beams, columns, and bars that form the framework of buildings and infrastructure projects. The process begins with steel billets, which are semi-finished products made from molten steel that has been cast into rectangular or square shapes. These billets are then further processed and transformed into specific construction components through various manufacturing techniques. One common application of steel billets is in the production of beams, which are essential for supporting the weight of floors, roofs, and walls in buildings. Billets are processed through rolling mills, where they are heated and passed through a series of rollers to shape them into the desired beam profile. This process allows for the production of beams of different sizes and lengths, catering to the unique requirements of each construction project. Steel billets are also used in the production of columns, which provide vertical support to structures. Similarly to beams, billets are processed through rolling mills to obtain the required column shape. The columns are then joined to the beams to form the skeletal framework of the building, providing strength and stability. In addition to beams and columns, steel billets are employed in the production of bars used for reinforcing concrete. These reinforcing bars, commonly known as rebar, are crucial for enhancing the strength and durability of concrete structures. Billets are again processed through rolling mills to create rebar of various diameters and lengths. The rebar is then embedded within the concrete to provide tensile strength, preventing cracking and increasing the overall structural integrity. Overall, steel billets play a vital role in the production of construction components by serving as the starting point for the manufacturing process. They are transformed into beams, columns, and rebar, providing the necessary strength and stability required in the construction of buildings and infrastructure projects.

- Q: Can steel billets be used in the production of mining equipment?

- Yes, steel billets can be used in the production of mining equipment. Steel billets are semi-finished products that are commonly used in the manufacturing industry to produce various types of steel products, including mining equipment. The high strength and durability of steel make it an ideal material for mining equipment, which often operates in harsh and demanding environments. Steel billets can be processed and shaped into different components such as gears, shafts, frames, and buckets, which are essential parts of mining equipment. Additionally, steel billets can be easily welded, machined, and heat-treated to meet the specific requirements and standards of mining equipment. Therefore, steel billets play a crucial role in the production of mining equipment by providing the necessary strength and reliability needed for safe and efficient mining operations.

- Q: Are steel billets subject to any regulations or certifications?

- Yes, steel billets are subject to various regulations and certifications. These regulations and certifications ensure that the steel billets meet specific quality standards, safety requirements, and environmental regulations. Some common certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and certifications from industry-specific organizations like the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). Additionally, steel billets may need to comply with specific regulations in the country or region where they are produced or used, such as building codes or product safety regulations.

- Q: Can steel billets be used in the production of bicycles?

- Certainly! Bicycles can indeed utilize steel billets in their production. Steel billets, which are partially finished products derived from steel, can undergo further processing to attain a wide range of shapes and sizes. When it comes to bicycles, these steel billets can be molded and fashioned into diverse components such as frames, forks, handlebars, and other structural elements. Steel remains a popular choice for bicycle production due to its commendable attributes of strength, durability, and cost-effectiveness. It offers exceptional rigidity, stability, and resistance to deformation, rendering it suitable for various bicycle types including road bikes, mountain bikes, and hybrid bikes. Furthermore, steel can be readily welded, enabling customization and facilitating the repair of bicycle frames.

- Q: How are steel billets made?

- Steel billets are made through a process called casting. It starts with raw materials such as iron ore, coal, and limestone being melted in a blast furnace to produce molten iron. This molten iron is then further refined in a basic oxygen furnace or an electric arc furnace to adjust its composition and remove impurities. Once the desired composition is achieved, the molten iron is poured into a continuous casting machine. This machine consists of a water-cooled copper mold that shapes the molten iron into a solid billet. As the molten iron is poured into the mold, it rapidly cools and solidifies, forming a continuous length of solid steel. The billet is then cut to the desired length and transferred to a storage area to cool down further before further processing. The cooling process is crucial as it helps in improving the billet's internal structure and overall quality. After cooling, the steel billets can undergo various treatments such as heat treatment or surface conditioning to enhance their mechanical properties and surface finish. They can also be further processed into different shapes and sizes through rolling, forging, or extrusion to meet specific customer requirements. Overall, the production of steel billets involves melting the raw materials, refining the molten iron, casting it into a continuous mold, and subsequently cooling and processing the solid billets. This process ensures the production of high-quality steel billets that serve as crucial building blocks for various industries such as construction, automotive, and manufacturing.

Send your message to us

Steel Billet high quality hot rolled in Best Price

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15921 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords