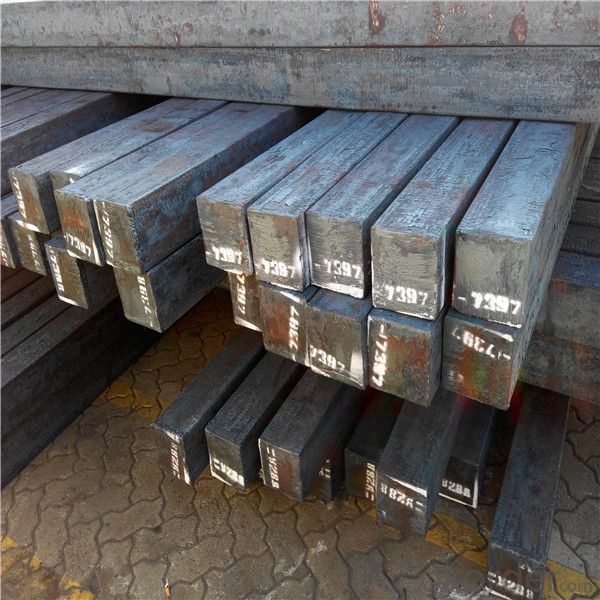

Billet steel from our own mill in good price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15250 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet

(ingot) by cogging or breakdown of semifinished products, is the raw material of all kinds of steel mill.

Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the

shape of rolled products.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base

building the support foundation pile manufacturing.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the environmental impacts of steel billet production?

- The environmental impacts of steel billet production include air pollution from emissions of greenhouse gases and particulate matter, water pollution from the discharge of wastewater containing heavy metals and other pollutants, and deforestation and habitat destruction due to the extraction of raw materials such as iron ore and coal. Additionally, the energy-intensive nature of steel production contributes to significant carbon dioxide emissions, contributing to climate change. Efforts are being made to reduce these impacts through technological advancements and the adoption of more sustainable practices.

- Q: How are steel billets used in the production of forgings?

- Steel billets are used as the starting material in the production of forgings. They are heated and shaped using specialized machinery and techniques to create the desired shape and size of the final forged product. The billets provide the necessary strength and durability required for forging processes, ensuring the resulting forgings possess the desired mechanical properties.

- Q: What are the different surface treatments for improved dimensional accuracy in steel billets?

- To enhance dimensional accuracy in steel billets, various surface treatments can be utilized. These treatments have the objectives of reducing surface imperfections, improving surface finish, and minimizing dimensional variations. Some commonly employed surface treatments for achieving improved dimensional accuracy in steel billets include: 1. Shot blasting: By forcefully propelling abrasive particles onto the billet's surface, shot blasting effectively eliminates dirt, scale, and surface contaminants. This results in a smoother and cleaner surface, thereby eliminating potential dimensional variations caused by surface irregularities. 2. Peeling: In this machining process, a cutting tool is used to remove a thin layer of material from the billet's surface. Peeling helps eliminate surface defects and imperfections, leading to enhanced dimensional accuracy. Additionally, peeling can improve the billet's surface finish. 3. Grinding: Material removal from the billet's surface is achieved through the use of an abrasive wheel or belt in the grinding process. This treatment effectively eliminates surface irregularities like high spots or scratches, contributing to improved dimensional accuracy. Furthermore, grinding provides a smoother and more uniform surface finish. 4. Turning: Using a cutting tool, turning involves the removal of material from the billet's surface. This treatment enables the achievement of precise dimensions and surface finish. Additionally, turning can enhance the billet's concentricity and straightness. 5. Polishing: Polishing entails the use of abrasive materials or compounds to create a smooth and reflective surface on the billet. By eliminating surface imperfections such as scratches or blemishes, polishing contributes to improved dimensional accuracy and surface finish. It is important to consider that the choice of surface treatment may vary depending on specific requirements and desired outcomes. Manufacturers often employ a combination of these treatments to attain optimal dimensional accuracy in steel billets.

- Q: How do steel billets affect the overall cost of a project?

- The overall cost of a project can be greatly affected by steel billets. To begin with, the price of steel billets can vary depending on factors like size, grade, and market demand. Higher quality or specialized billets may be more expensive, while lower quality or easily accessible ones may be more cost-efficient. Moreover, the quantity of steel billets needed for a project can significantly impact the total cost. Larger projects that require a substantial amount of steel may have to purchase a greater number of billets, thus increasing the cost. Conversely, smaller projects with fewer steel needs may be able to minimize expenses by purchasing a smaller quantity of billets. The cost of transportation and logistics also plays a role in the overall cost of steel billets. The distance between the billet supplier and the project site, as well as the availability of transportation options, can affect the final cost. Expenses such as shipping costs, handling fees, and other associated charges can add to the overall project cost. Furthermore, the quality and suitability of the steel billets for the specific project requirements can impact costs. The use of low-quality or unsuitable billets may result in delays, rework, or even project failure, leading to additional expenses. Hence, it is crucial to ensure that the chosen steel billets meet the necessary specifications and standards, even if they come with a higher initial cost. Lastly, market conditions and fluctuations in the steel industry can influence the cost of steel billets. Factors like supply and demand, currency exchange rates, and global economic trends can affect the price of billets, thereby impacting the overall project cost. In conclusion, the cost of steel billets can have a significant impact on the overall cost of a project. Factors such as the price of the billets themselves, the quantity required, transportation and logistics, quality and suitability, and market conditions all contribute to the final cost. Therefore, careful consideration and analysis of these factors are essential for effective management and budgeting of steel billets in a project.

- Q: How are steel billets used in the production of bars and rods?

- Steel billets are an essential raw material used in the production of bars and rods. These billets, which are usually produced through a process called continuous casting, are solid blocks of semi-finished steel with a square or rectangular cross-section. To transform steel billets into bars and rods, several steps are involved. First, the billets are reheated to a specific temperature in a furnace to make them more malleable. This heating process, known as soaking, helps to homogenize the steel's composition and improve its plasticity. Once the billets reach the desired temperature, they are then passed through a series of rollers in a process called hot rolling. The rollers apply pressure to the billets, gradually reducing their cross-sectional area and elongating them into long, slender shapes. This hot rolling process helps to refine the grain structure of the steel, align its crystalline structure, and improve its mechanical properties. After hot rolling, the bars and rods are often subjected to further processes, such as cooling, straightening, and cutting. Cooling is crucial to prevent the steel from becoming too brittle, while straightening ensures the final product has the desired shape and dimensions. Finally, the bars and rods are cut into specific lengths, ready to be used in various industries such as construction, automotive, and manufacturing. In summary, steel billets form the starting point for the production of bars and rods. Through processes like reheating, hot rolling, and subsequent treatments, these billets are transformed into high-quality, durable bars and rods that are widely used in various applications.

- Q: How are steel billets used in the production of gear blanks?

- Gear blanks are made from steel billets, which are essential for their production. Steel billets are long bars of steel that possess the necessary characteristics for gear manufacturing. These billets are made from high-quality steel and provide the material needed for creating gear blanks. To shape the gear blanks, the steel billets are heated to a specific temperature, making them easier to work with. Various forming processes, such as forging or extrusion, are then used to transform the billets into the desired shape of the gear blank. Once the gear blank is formed, it undergoes further machining processes to refine its shape, dimensions, and surface finish. This includes turning, milling, drilling, or grinding operations. Precise machining is necessary to meet the required specifications for the final gear product. The gear blanks produced from steel billets are the foundation for creating different types of gears, including spur gears, helical gears, bevel gears, or worm gears. These gear blanks undergo additional steps, such as heat treatment and surface hardening, to enhance their mechanical properties and increase their resistance to wear and fatigue. In conclusion, steel billets are crucial in the production of gear blanks as they provide the raw material for creating gears. Through heating, forming, and machining processes, the steel billets are transformed into gear blanks, which are then further processed to create the final gears used in various applications.

- Q: Can steel billets be used for making architectural structures?

- Yes, steel billets can be used for making architectural structures. Steel billets are commonly used as a raw material in the construction industry for various applications including the fabrication of beams, columns, and other structural components. The high strength and durability of steel make it an ideal choice for architectural structures, providing stability and structural integrity to buildings.

- Q: How are steel billets tested for internal defects?

- Steel billets are tested for internal defects through a variety of non-destructive testing methods. One of the most common methods used is ultrasonic testing (UT). During this process, high-frequency sound waves are transmitted into the billet, and the reflections of these waves are analyzed to detect any internal defects such as cracks, voids, or inclusions. UT can provide accurate and detailed information about the size, location, and nature of the defects. Another method used is magnetic particle inspection (MPI). This technique involves magnetizing the billet and applying iron particles to its surface. If there are any internal defects, the magnetic field will cause these particles to gather around them, making them visible and detectable. Eddy current testing (ECT) is also employed to assess the internal quality of steel billets. It utilizes electromagnetic induction to create eddy currents within the material. Any changes in the electrical conductivity or magnetic permeability caused by internal defects can be detected by analyzing the variations in the induced current. Additionally, radiographic testing (RT) is utilized to inspect the internal structure of steel billets. X-rays or gamma rays are directed towards the billet, and the resulting radiographic image can reveal any internal defects such as voids, cracks, or inclusions. Other methods, such as dye penetrant testing and visual inspection, can also be used to detect superficial and near-surface defects in steel billets. These methods involve applying a liquid or dye to the surface of the billet, which will seep into any cracks or surface irregularities, making them visible under certain lighting conditions. Overall, a combination of these non-destructive testing methods is employed to ensure the quality and integrity of steel billets by effectively detecting any internal defects that could compromise their structural integrity and performance.

- Q: How are steel billets used in the manufacturing of industrial machinery parts?

- Steel billets are an essential component in the manufacturing of industrial machinery parts due to their unique properties and versatility. These billets are semi-finished steel products that are typically cast in a square or rectangular shape. They serve as the starting material for various industrial machinery parts, including gears, shafts, pistons, and other critical components. The first step in utilizing steel billets is to heat them to a specific temperature, which allows for easier manipulation and shaping. Once heated, the billets undergo a process called hot rolling, where they are passed through a series of rollers to reduce their cross-sectional area and increase their length. This process not only enhances the strength and durability of the steel but also refines its microstructure, resulting in improved mechanical properties. After hot rolling, the steel billets are typically further processed through machining operations such as cutting, drilling, milling, and grinding to achieve the desired dimensions and specifications required for specific machinery parts. These operations ensure precision and accuracy, allowing for seamless integration of the parts into the overall machinery assembly. Steel billets are particularly favored in the manufacturing of industrial machinery parts due to their high strength, toughness, and resistance to wear and tear. Their excellent machinability enables complex designs and intricate patterns to be achieved, ensuring optimal functionality and performance of the machinery. Moreover, steel billets can be easily welded, making them suitable for joining multiple parts together to create more substantial and robust structures. In conclusion, steel billets play a crucial role in the manufacturing of industrial machinery parts. By providing a strong, durable, and versatile starting material, they enable the creation of precise and reliable components that ensure the smooth operation of industrial machinery in various sectors such as manufacturing, construction, and transportation.

- Q: What are the different methods of steel billet surface shot blasting?

- There are several different methods of steel billet surface shot blasting that are commonly utilized in various industries. These methods include: 1. Wheel blasting: This method involves using a wheel mechanism to propel abrasive particles onto the surface of the steel billet. The wheel rotates at a high speed, creating centrifugal force that propels the abrasives towards the billet, effectively removing any impurities or surface contaminants. 2. Air blasting: Air blasting is another commonly used method, where compressed air is used to propel abrasive particles onto the surface of the steel billet. The compressed air creates a high-pressure stream that propels the abrasives, effectively cleaning and preparing the surface. 3. Wet blasting: This method involves combining water with the abrasive particles before propelling them onto the steel billet surface. The addition of water helps to minimize dust and control the heat generated during the blasting process. Wet blasting is often used for steel billets that require a more delicate or controlled surface cleaning. 4. Shot peening: Shot peening is a specialized method used to improve the fatigue life and strength of the steel billet surface. In this process, small steel shots are propelled onto the surface with controlled intensity, creating compressive stresses that help to prevent crack initiation and propagation. 5. Vacuum blasting: Vacuum blasting is a method that combines a blast nozzle with a vacuum system. The abrasive particles are propelled onto the steel billet surface, and simultaneously, a vacuum system removes the spent abrasive particles and any loose debris. This method ensures a clean and dust-free environment during the blasting process. It's important to note that the choice of method will depend on various factors such as the type and condition of the steel billet, the desired surface finish, the level of contamination, and the specific requirements of the industry. Each method has its own advantages and limitations, and selecting the appropriate method is crucial to achieve the desired surface quality and cleanliness.

Send your message to us

Billet steel from our own mill in good price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15250 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords