Embossed Aluminum Sheets with Better Price in Warehouse with Stocks Price

- Loading Port:

- Qingdao

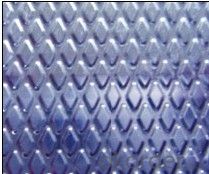

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum sheet and aluminum plate and aluminium slab are all widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,O,H114,etc.

2. Main features of the product

a.Competitive price

b. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,500mm*500mm, 2000mm*2000mm, etc.

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 100mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 13 tons/each size.

How many tons did you export in one year

USA, japan, UAE, Vietnam, Canada, etc.

What is your mainly products?

---Normally finish aluminium sheet, aluminum casting coil,aluminum composite panel, aluminum sandwich panel, ACP, etc.

- Q: This question asks for methods to prevent rusting on aluminum sheets during the installation process.

- <p>To prevent rusting on aluminum sheets during installation, ensure that the aluminum is of high quality and free from impurities. Keep the surface clean and dry at all times, avoiding contact with corrosive materials. Use appropriate protective coatings or sealants that are compatible with aluminum. Avoid scratches or dents that can expose the metal to moisture. Store aluminum sheets in a dry place before installation. During installation, handle the sheets carefully to avoid damage. Regularly inspect and maintain the aluminum sheets to catch any signs of corrosion early.</p>

- Q: Can aluminum sheets be used in food packaging?

- Yes, aluminum sheets can be used in food packaging. Aluminum is a common material choice for food packaging due to its excellent barrier properties, durability, and ability to maintain the freshness and quality of food products. It is also lightweight, recyclable, and resistant to moisture, odors, and UV light.

- Q: What is the typical modulus of elasticity of aluminum sheets?

- The typical modulus of elasticity of aluminum sheets varies depending on the alloy and temper. However, a commonly used value is around 70 GPa (gigapascals) or 10 million psi (pounds per square inch). This value represents the stiffness or rigidity of the material, indicating its ability to withstand deformation under applied stress. It is important to note that different grades and conditions of aluminum may have slightly different modulus of elasticity values, so it is recommended to consult the specific material specifications for accurate information.

- Q: Can aluminum sheets be used for electrical conductors?

- Yes, aluminum sheets can be used for electrical conductors. Aluminum is a good conductor of electricity, although it is not as efficient as copper. However, aluminum is often used in electrical applications due to its lightweight nature, cost-effectiveness, and corrosion resistance. It is commonly used in power distribution lines, wiring systems, and electrical equipment.

- Q: What is the difference between aluminum plate and aluminum-plastic plate?

- Aluminum sheet: aluminum or aluminum alloy (strip) as the base material, processed by molding and surface protection and decorative coating or anodized film of single aluminum sheet (sheet) called aluminum veneer. Aluminum veneer is widely used for architectural decoration called architectural aluminum veneer, the implementation of GB/T23443-2009 standards.Two, aluminum plate: the full name is called aluminum-plastic composite board. The utility model relates to a three layer composite decorative board with plastic as core material, aluminum sheet (sheet) on both sides, and protective coating and decorative coating on the surface of aluminum. There are two kinds of aluminum-plastic panels, one is common decorative aluminum plate, the implementation of GB/T22412-2008; one kind of building curtain wall with aluminum plate, the implementation of GB/T17748-2008.The difference between the three, aluminum single plate and aluminum plate: 1, aluminum veneer is a single plate, only raw materials, namely, aluminum strip and aluminum plate; three layer composite plate, the two sides for aluminum (film) commonly known as aluminum substrate or aluminum substrate, the middle layer is a plastic commonly known as plastic core material, raw materials there are two kinds, one is aluminum plate, two plastic core material; 3, aluminum veneer thickness is generally of no limit, if too thick aluminum plate aluminum base composite is not strong, at present in the world within the scope of the general requirements of aluminum substrate thickness limit of not more than 1mm. The above is the main difference between the aluminum sheet and the aluminum-plastic plate. Upstairs answer, some are wrong, for example, "2", the quality is different: because aluminum plate is less than aluminum plate, aluminum layer, so the aluminum plate than aluminum plate quality must be worse." Please survey.

- Q: Curtain wall aluminum plate reinforcement spacing between the number of appropriate, the country has no standard?

- As to the stiffener of the aluminum veneer, what are the following points?:1, aluminum reinforcement spacing is generally around 600mm, in order to ensure the aluminum plate in the positive and negative pressure conditions within the scope of deformation. When aluminum plate is welded, there is internal stress due to welding deformation (this internal stress can not be completely eliminated for a long time), and the rigidity of reinforcing bar should also be increased.2. The sectional dimension and spacing of stiffeners shall be determined according to the calculated wind pressure of the aluminum plate. But it is worth noting that the reinforcement calculation of single aluminum plate strengthening is different from the glass curtain wall, first, its strength is certainly no problem (still not seen the wind blowing broken plate, there is no joke) deflection possibility, bend off and windy weather also very few people to pay attention to the single aluminum plate plate surface after deformation the scenery. Therefore, the calculation of deflection of stiffeners are considered under the condition of wind strength and deflection when the winds of aluminum can cause permanent plastic deformation.In fact, aluminum veneer manufacturers generally use the single aluminum plate edge folding groove made of aluminum and 20*40*20, installed in the distance about 600mm. Also useful for profile (grooved aluminum) stiffenersThe spacing between stiffeners is very important to the cost of production. Generally speaking, the spacing of stiffeners will be changed from 600 to 350, and the cost will be increased by 8~15 yuan / square meter

- Q: How does my world Pocket Monster mod aluminum plate synthesize?

- Right on the ball cover and the aluminum ball low and then use the hammer on the anvil.

- Q: Are aluminum sheets suitable for architectural roofing?

- Yes, aluminum sheets are suitable for architectural roofing. Aluminum is a lightweight material that is resistant to corrosion, making it an ideal choice for roofing applications. It is also highly durable and can withstand harsh weather conditions, including extreme temperatures, UV radiation, and strong winds. Additionally, aluminum sheets are available in a variety of colors and finishes, allowing for flexibility in design and aesthetics. Moreover, aluminum is a sustainable and environmentally friendly material as it can be recycled indefinitely without losing its properties. Overall, aluminum sheets provide excellent performance and versatility, making them a popular choice for architectural roofing.

- Q: What specific conditions are necessary for the storage and transportation of aluminum sheets to ensure their quality and safety?

- <p>Yes, there are special requirements for storing and transporting aluminum sheets. Aluminum sheets should be stored in a dry, cool place to prevent moisture and temperature extremes which can cause warping or corrosion. They should be stacked flat and evenly to avoid bending or denting. When transporting, aluminum sheets should be secured to prevent shifting during transit, which can lead to damage. Protective coverings may be used to shield the sheets from dirt, scratches, or other potential hazards. It's also crucial to handle the sheets carefully to avoid bending or denting, which can occur if they are not properly supported during transport.</p>

- Q: Are aluminum sheets suitable for artistic sculptures?

- Yes, aluminum sheets are suitable for artistic sculptures. Aluminum is a versatile material that offers several advantages for sculpting purposes. Firstly, it is lightweight, making it easier to handle and manipulate. This allows artists to create intricate and detailed sculptures without compromising on structural integrity. Additionally, aluminum is highly malleable, meaning it can be shaped into various forms and contours. This allows artists to experiment with different designs and achieve the desired artistic expression. Furthermore, aluminum is resistant to corrosion and weathering, making it ideal for outdoor sculptures. Its durability ensures that the artwork will withstand the elements and retain its aesthetic appeal over time. Additionally, aluminum sheets can be easily welded or joined together, enabling artists to create larger and more complex sculptures. Overall, aluminum sheets provide artists with a flexible and durable material that allows for creativity and longevity in their sculptural works.

Send your message to us

Embossed Aluminum Sheets with Better Price in Warehouse with Stocks Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords