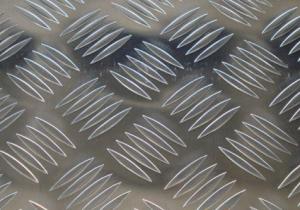

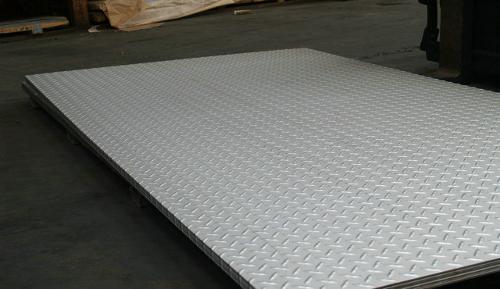

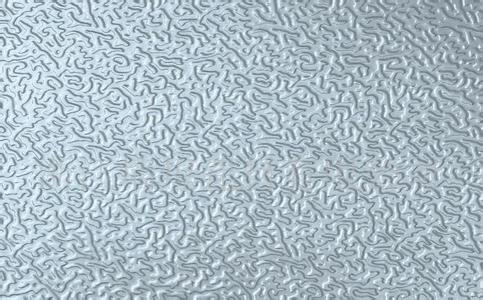

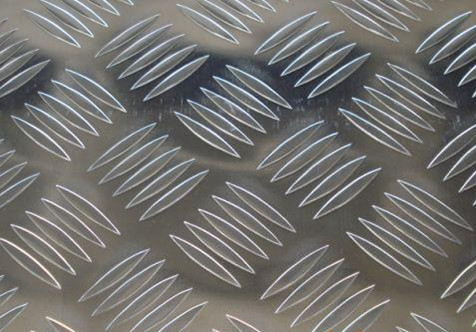

Sublimation Embossed Aluminum Metal Sheets 1xxx3xxx5xxx Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Foil

Often referred to as tin foil, is aluminium prepared in thin metal leaves with a thickness less than 0.2 mm (7.9 mils); thinner gauges down to 6 micrometres (0.24 mils) are also commonly used. In the United States, foils are commonly gauged in thousandths of an inch or mils. Standard household foil is typically 0.016 mm (0.63 mils) thick, and heavy duty household foil is typically 0.024 mm (0.94 mils). The foil is pliable, and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimes laminated to other materials such asplastics or paper to make them more useful. Aluminium foil supplanted tin foil in the mid 20th century.

2.Main Features of the Aluminum Foil

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

6.Our quality is based on EN,ASTM,JIS.

7.We provide free sample service.

8.The products can be made according to your requirement.

9.Sincerely welcome your inquiry.

3. Aluminium Foil Images:

4. Aluminium Foil Specification:

Product application range:

Suitable for: Tobacco, food, beer, beverage, decoration, electric cable, electrolytic capacitor, medicine and air-conditioner.

Alloy: 1070\1060\1050\110\1200\1145\1235\3003\3102\8011\8011A\8079\8006

Temper:0/H14\H16\H18\H26\H24\H22

Thickness: 0.006mm_0.2mm

Width: 75 mm-1410 mm

Coil inner diameter: 75.00\ 76.20\ 150.00\ 200.00mm

Aluminum foil coil outer diameter:100 mm-1000 mm

Industry | Type | Typical thickness (mm) | Processing method | Usage |

Packing | Food | 0.006-0.009 | Compound paper, plastics, thin film, embossing & colorizing, printing | Candy, milk and milk product, powder food, drink, tea, bread and all kinds of snack food |

Tobacco | 0.006-0.007 | Compound paper, colorizing, printing | Internal and external packing for cigarette | |

Medicine | 0.006-0.02 | Compounding, coating, printing | Tablet, granular formulation | |

Cosmetics | 0.006-0.009 | Compound printing | ||

Bottle caps | 0.011-0.2 | Printing, scouring printing | Bottle caps, the beer bottle, the fruit juice bottle seal, all kinds of trademarks, etc. | |

Daily use | Household | 0.01-0.2 | Small coiling | Packing for family food etc. |

Utensils | 0...011-0.1 | Molding processing | Food utensils, coal gas hood, ashtray and all kinds of utensils | |

Electrical equipment industry | electrolytic capacitor | 0.015-0.11 | Eroding in the special medium | electrolytic capacitor |

Electrolytic capacitor | 0.006-0.016 | Liner oil paper | capacitor | |

Radiator | 0.09-0.2 | Punching Fin | All kinds of air conditioning radiators | |

Electric cable | 0.15-0.2 | aluminium plastics compound | Electric cable wrap | |

Construction industry | Heat-insulating material | 0.006-0.03 | compound materials | Heat-insulating material for house, pipeline etc. |

Decorating board | 0.03-0.2 | Paints coated compound materials | Decorating board for construction use | |

Aluminium plastic pipeline | 0.2 | Compound polyethylene plastic | All kinds of pipelines | |

Special specification | Air conditioning foil | 0.105-0.115 | 8011 H22 O | |

Wine banner foil | 0.0105-0.0115 | 8011 O | ||

Foil for medicine | 0.02-0.025 | 8011 H18 |

5. FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are aluminum sheets suitable for construction in regions with a high risk of earthquakes?

- <p>Aluminum sheets can be used in earthquake-prone areas, but their suitability depends on the specific application and construction methods. Aluminum is lightweight and flexible, which can be advantageous in withstanding seismic forces. However, it lacks the strength and rigidity of traditional materials like steel and concrete. When used in construction, aluminum must be properly engineered and combined with other materials to ensure structural integrity and compliance with seismic building codes. It's crucial to consult with structural engineers and follow local regulations when considering aluminum for earthquake-prone regions.</p>

- Q: What are the different types of surface treatments available for architectural aluminum sheets?

- Architectural aluminum sheets come with a variety of surface treatments that serve to improve their appearance, durability, and performance. These treatments make the aluminum suitable for a wide range of architectural applications. One commonly used surface treatment is anodizing. This process entails immersing the aluminum sheet in an electrolytic solution and applying an electric current to create a protective oxide layer on its surface. This oxide layer can be dyed to achieve the desired color or left clear to maintain a natural metallic appearance. Anodized aluminum sheets are highly regarded for their excellent resistance to corrosion, scratches, and color fading. Another surface treatment option is powder coating. In this method, a dry powder is electrostatically applied to the aluminum sheet and then cured in an oven. The powder melts and fuses to the surface, resulting in a smooth and durable finish. Powder coating offers exceptional color retention, weather resistance, and resistance to chipping and cracking. A third type of surface treatment is PVDF coating, which involves applying a high-performance fluoropolymer resin called polyvinylidene fluoride to the aluminum sheet through a coil coating process. PVDF coatings are known for their exceptional resistance to fading, chalking, and chemical attack, making them perfect for exterior applications where color retention and durability are crucial. Additionally, there are various mechanical surface treatments available for architectural aluminum sheets. These treatments, such as brushing or polishing, can be employed to achieve the desired texture or reflectivity on the surface. Mechanical treatments allow for the creation of brushed, satin, or mirror-like finishes, adding aesthetic appeal to the aluminum sheet. To summarize, architectural aluminum sheets can be treated using anodizing, powder coating, PVDF coating, or mechanical treatments. Each treatment offers unique advantages and characteristics, enabling architects and designers to select the most suitable option for their specific project requirements.

- Q: What specific conditions or regulations must be met when using aluminum sheets in commercial construction?

- <p>Yes, there are special requirements for using aluminum sheets in commercial buildings. These include adherence to building codes and standards for fire resistance, structural integrity, and weather resistance. Aluminum sheets must meet specific thickness and strength requirements depending on the application. They also need to comply with environmental regulations regarding sustainability and recyclability. Additionally, for aesthetic purposes, the finish and color of the aluminum sheets should be in line with architectural design guidelines. It's crucial to consult with architects, engineers, and local building authorities to ensure all requirements are met.</p>

- Q: Are aluminum sheets suitable for aerospace wing structures?

- Yes, aluminum sheets are suitable for aerospace wing structures. Aluminum is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and its ability to withstand high temperatures. Aluminum alloys, such as 2024 and 7075, are commonly used for wing structures as they provide high strength and durability. Additionally, aluminum can be easily formed into different shapes and sizes, allowing for the production of complex wing designs. Overall, aluminum sheets offer a combination of lightweight properties, strength, and reliability, making them highly suitable for aerospace wing structures.

- Q: This question asks about the various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with various materials to enhance their properties such as corrosion resistance, appearance, and durability. Some common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the surface. 2. Powder coating, a dry coating that is electrostatically applied and then cured at high temperatures. 3. Paint coating, which can be either liquid or powder-based and provides a decorative and protective layer. 4. Vinyl coating, which is a plastic coating applied for a smooth, matte finish. 5. Electrolytic coating, which involves depositing a thin layer of metal onto the aluminum surface. 6. Hot-dip coating, where aluminum is coated with a layer of zinc or other metals by dipping it into a molten bath. Each type of coating serves different purposes and has unique characteristics.</p>

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed. Roll forming is a process in which a continuous strip of metal, in this case, aluminum, is fed through a series of rollers to gradually shape it into a desired profile or shape. Aluminum is an ideal material for roll forming due to its malleability and ductility, allowing it to be easily bent, curved, and formed into various shapes. It is commonly used in industries such as construction, automotive, and aerospace for applications that require lightweight yet durable components.

- Q: What is the cost of aluminum sheets compared to other materials?

- The price of aluminum sheets can vary based on factors such as thickness, size, quality, and market conditions. Nevertheless, when compared to materials like stainless steel or copper, aluminum sheets are generally more cost-effective. This is because aluminum is easily accessible and has a lower production cost, leading to its relatively affordable price. Moreover, aluminum is lightweight, durable, and resistant to corrosion, making it a favored option in many industries. It is important to consider that prices may change due to market demand, raw material availability, and other economic influences.

- Q: Are aluminum sheets suitable for bulletproof applications?

- No, aluminum sheets are not suitable for bulletproof applications.

- Q: I just built a stone wall with illuminated glass features embedded, and to make them shine evenly, I had all sides but the visual one wrapped in industrial thickness aluminium foil. One week later, the foil has disintegrated. I have used type 10 Portland. What is going on?

- I believe your problem is that concrete acts as a fairly strong base (this is especially true of mortar mixes). It is well known that strong base will react with an active metal like aluminium and produce hydrogen gas as a byproduct. The representative reaction is: 2Al+6NaOH==2Na3AlO3+3H2, This reaction is fairly rapid and can even cause an explosive buildup of hydrogen gas in a non-ventillated area.

- Q: is putting Aluminium foil behind the wind shield actually generate more heat and make the car hotter inside or make the car inside cooler? assume you put foil behind all windows.

- Aluminum foil will absorb heat, just like any other metal (and anything for that matter, but this isn't a discussion about conductors vs. insulators). Whether aluminum foil absorbs heat is the essential issue here. A car gets hot in the sun as a result of the sunlight shining on the car. When the sun shines on a car, the light passes through the windows (because windows are clear) and is absorbs by the interior of the car (e.g. the seat cushions). The absorbed energy is given off as heat, which is trapped in the car (heat doesn't pass through windows like sunlight does). By putting aluminum reflectors in your windshield, you are reflecting away the light and preventing it from reaching the interior of your car. For this reason, putting aluminum shielding in the windows of your car actually keeps your car cooler, and not hotter.

Send your message to us

Sublimation Embossed Aluminum Metal Sheets 1xxx3xxx5xxx Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords