Aluminum Sublimation Sheets - Brushed Aluminum Sheet Sizes in All Kinds Available

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheet Sizes in All Kinds Available

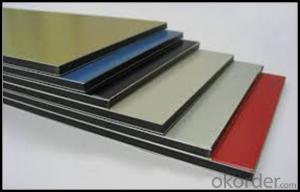

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Sheet Sizes in All Kinds Available

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

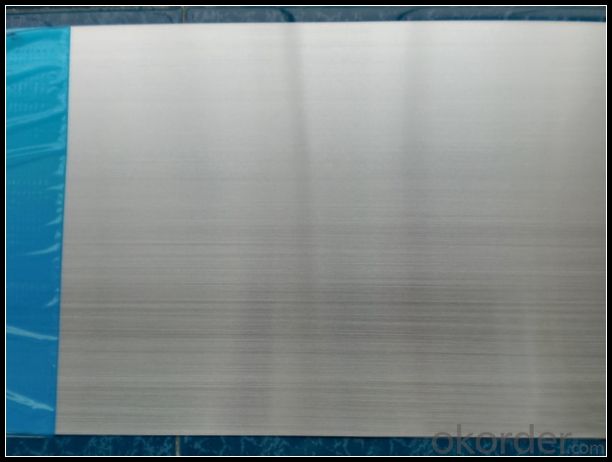

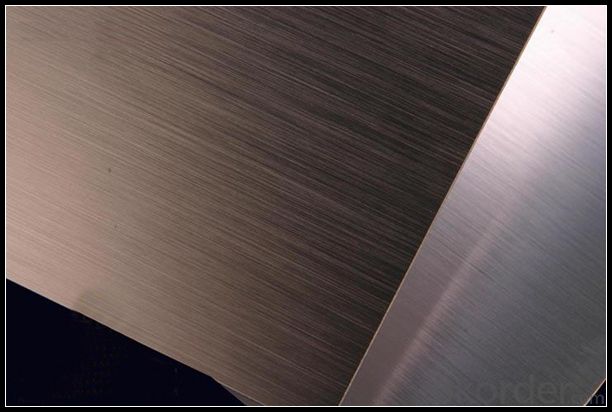

3. Aluminum Sheet Sizes in All Kinds Available Images

4.Specification of Aluminum Sheet Sizes in All Kinds Available

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: This question asks for a comparison between aluminum sheets and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum sheets are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are energy-efficient, reflecting heat and reducing cooling costs. Compared to materials like asphalt shingles, aluminum is more expensive but lasts longer, with a lifespan of 40-50 years. Unlike clay or concrete tiles, aluminum is less prone to breakage and is easier to install. It also doesn't rot or warp like wood, and it's fire-resistant. However, it can be noisy during rain and is less visually appealing than some other materials, but its modern and sleek appearance can be a design advantage.</p>

- Q: What are the rules and standards that govern the use of aluminum sheets in construction projects?

- <p>Yes, there are regulations regarding the use of aluminum sheets in construction. These regulations vary by country and region but generally cover aspects such as material standards, safety, and environmental impact. For instance, in the United States, the American Society for Testing and Materials (ASTM) provides standards for aluminum sheet materials. Building codes like the International Building Code (IBC) also specify requirements for the use of aluminum in construction. These regulations ensure that aluminum sheets meet certain strength, durability, and performance criteria. Compliance with these regulations is crucial for safety, structural integrity, and to obtain necessary permits and approvals for construction projects.</p>

- Q: I am looking for info on grades of aluminum like 3003, 5053, 6160 what's the differance witch one are cheaper and weld easy please explain

- 1) okorder /

- Q: Are the aluminum sheets suitable for manufacturing electrical busbars?

- Yes, aluminum sheets are suitable for manufacturing electrical busbars. Aluminum is a popular choice for busbars due to its excellent electrical conductivity and lightweight properties. It can efficiently conduct high electrical currents and has low resistance, making it ideal for conducting electricity in power distribution systems. Additionally, aluminum sheets can be easily fabricated and formed into various shapes and sizes, allowing for customization and efficient installation in electrical systems.

- Q: I'm was thinking of buying an aluminium bike but I saw some good bikes with hi-ten.

- Get an aluminum frame Hi-ten steel is the buzz word for cheap plain steel.

- Q: Can aluminum sheets be used for structural purposes?

- Yes, aluminum sheets can be used for structural purposes. Aluminum is a lightweight and highly malleable material that can be easily fabricated into various shapes and sizes. It has excellent strength-to-weight ratio, making it suitable for structural applications where weight reduction is a priority. Aluminum sheets are commonly used in industries such as aerospace, automotive, and construction for making structural components like panels, beams, and frames. Additionally, aluminum has good corrosion resistance, which further enhances its suitability for structural purposes, especially in outdoor or marine environments. Overall, aluminum sheets offer a reliable and cost-effective solution for structural applications.

- Q: Are the aluminum sheets suitable for manufacturing solar reflectors?

- Aluminum sheets, indeed, prove to be fitting for the production of solar reflectors. As a material, aluminum possesses high reflectivity, enabling it to efficiently bounce off sunlight, thereby making it an optimal selection for solar reflectors. Its remarkable reflectivity and minimal heat absorption, owing to its low emissivity, allow it to effectively deflect a substantial amount of solar radiation. Moreover, aluminum exhibits qualities of being lightweight, long-lasting, and resistant to corrosion, rendering it appropriate for outdoor usage. Furthermore, its malleability permits simple shaping and molding into diverse reflector designs. All in all, aluminum sheets offer exceptional performance and dependability when it comes to constructing solar reflectors in solar energy systems.

- Q: How does the thermal conductivity of aluminum compare to other metals?

- The thermal conductivity of aluminum is relatively high compared to many other metals. It is often considered one of the best conductors of heat among common metals. Aluminum has a thermal conductivity of about 205 watts per meter kelvin (W/m·K), which is higher than copper (about 401 W/m·K) and even silver (about 429 W/m·K). This means that aluminum can transfer heat more efficiently than most other metals, making it a popular choice for heat sinks, radiators, and other applications that require effective heat dissipation. However, it is worth noting that some metals, such as diamond and graphene, have even higher thermal conductivity than aluminum.

- Q: What are the different methods of surface etching for aluminum sheets?

- There are several methods of surface etching for aluminum sheets, each with its own advantages and applications. Some of the most common methods include: 1. Chemical etching: This method involves using a chemical solution to selectively remove a thin layer of aluminum from the surface. The solution typically contains acids or alkaline substances that dissolve the metal, creating a textured or patterned surface. Chemical etching is precise and can achieve intricate designs, making it ideal for decorative or aesthetic purposes. 2. Mechanical etching: Also known as abrasive blasting or sanding, mechanical etching involves using abrasive materials such as sandpaper or wire brushes to physically remove the top layer of aluminum. This method is relatively simple and can be done manually or with the help of machinery. Mechanical etching is commonly used to create a uniform matte finish or to prepare the surface for further treatments, such as painting or coating. 3. Electrochemical etching: This method utilizes an electrical current to selectively dissolve the aluminum surface. The aluminum sheet is immersed in an electrolyte solution, and a direct current is applied through a stencil or mask to create the desired pattern. Electrochemical etching is commonly used for marking or labeling purposes on aluminum sheets, as it can produce clear, permanent, and highly precise designs. 4. Laser etching: Laser etching involves using a high-powered laser to remove the top layer of aluminum, creating a permanent and precise pattern on the surface. This method is highly accurate and can achieve intricate designs with sharp edges. Laser etching is commonly used for industrial applications, such as marking serial numbers, logos, or barcodes on aluminum sheets. 5. Photochemical etching: This method involves using a photosensitive material, known as a photoresist, to create a pattern on the aluminum surface. The aluminum sheet is coated with the photoresist, exposed to UV light through a stencil or mask, and then developed to remove the unexposed areas. The exposed aluminum is then etched away using a chemical solution. Photochemical etching is commonly used for producing high-resolution designs or microstructures on aluminum sheets. Each of these methods has its own advantages, depending on the desired outcome and application. It is important to consider factors such as precision, speed, cost, and complexity when choosing the appropriate surface etching method for aluminum sheets.

- Q: Can the aluminum sheets be used for manufacturing decorative trim?

- Indeed, the utilization of aluminum sheets is viable for the production of decorative trim. Being a versatile substance, aluminum is renowned for its lightweight nature, durability, and exceptional resistance to corrosion. It bestows the convenience of effortless shaping and molding into diverse decorative configurations and motifs. Furthermore, aluminum's aesthetic allure can be accentuated by applying coatings or paints of assorted hues. Consequently, aluminum sheets emerge as a highly favored option for fabricating decorative trim across a multitude of sectors, encompassing architecture, automotive, and interior design.

Send your message to us

Aluminum Sublimation Sheets - Brushed Aluminum Sheet Sizes in All Kinds Available

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords