Wholesale Sublimation Aluminum Sheets - Aluminium Composite Panel PE Good Price High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Aluminium Coil:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Prepainted Aluminium Coil:

High intensity.

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance.

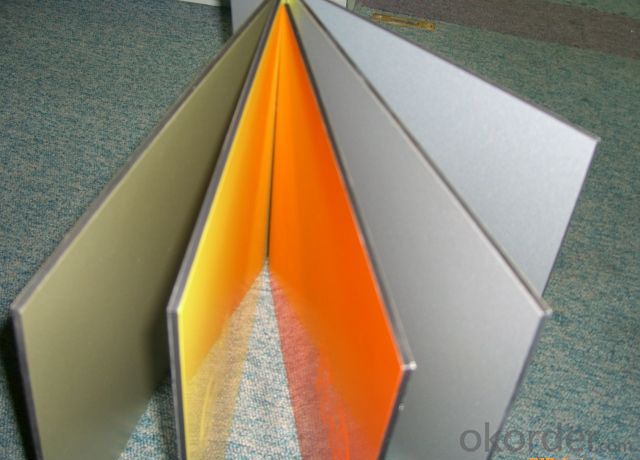

Images of Prepainted Aluminium Coil:

Prepainted Aluminium Coil Specifications:

Alloy | 1050 1060 1100 3003 3004 3005 3014 3105 3A21 5A02 5005 5052 5083 5251 6061 6063 etc |

Temper | F O H12 H22 H14 H24 H16 H26 H18 H32 H34 H38 H111 H1112 H116 H321 T5 T6 etc |

Thickness | 0.02mm - 1.2mm |

Width | Standard width: 1200mm 1240mm ; Special width:1300mm 1520mm 1570mm 1595mm |

Diameter | Standar dia: 1200mm ; Interior dia: 150mm 405mm 505mm |

Weight | 1 T / coil -- 3 T / coil |

Coating | PE PVDF ACRYLIC |

Surface | Coated , Mill Finish ,Embossed |

Color | Ral Color |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron PVDF : more than 25 micron |

Coating Hardness (pencilresistance) | More than 2 h |

Coating Adhesion | 5J (EN ISO - 2409 : 1994 ) |

Impact Resistance | No peeling or cracking (50kg / cm ,ASTMD - 2794 : 1993 ) |

Flexibility(T-bend) | 2 T |

MEK resistance | More than 100 |

MOQ | 2 T |

Payment Terms | TT or LC at sight |

Applycation | Mainly in construction, decoration ,PCB materials, labels, house hold appliance ,lift, cover material ,LCD back panel, refrigeration, air conditioner ,automobile etc |

FAQ of Prepainted Aluminium Coil:

a: Where is your factory?

Henan Provence.

b:Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: How do 101 aluminum sheets compare in terms of strength and durability?

- The mechanical properties and performance characteristics of 101 aluminum sheets are used to evaluate their strength and durability. In terms of strength, these sheets possess moderate strength that is appropriate for various applications. They have a tensile strength of approximately 27,000 psi and a yield strength of around 21,000 psi. This means that they can withstand moderate levels of stress and load without deforming or breaking. Regarding durability, 101 aluminum sheets exhibit good resistance to corrosion, making them suitable for outdoor and marine applications. They also have high resistance to different forms of weathering, including UV radiation and extreme temperatures. Their corrosion resistance is primarily due to the presence of a thin, protective oxide layer on the surface, which prevents further oxidation and ensures long-lasting durability. However, it is important to note that 101 aluminum sheets are not the most durable option available. They are not as strong or durable as certain other aluminum alloys, such as 6061 or 7075, which have higher tensile and yield strengths. Therefore, if a project requires exceptional strength or durability, it may be advantageous to consider using a different aluminum alloy. In conclusion, 101 aluminum sheets offer moderate strength and good durability, making them suitable for a wide range of applications. Nevertheless, if the project necessitates higher strength or exceptional durability, it may be necessary to explore alternative aluminum alloys with superior mechanical properties.

- Q: Can aluminum sheet be used for signage?

- Yes, aluminum sheet can be used for signage due to its durability, lightweight nature, and resistance to corrosion, making it a popular choice for a wide range of indoor and outdoor signage applications.

- Q: This question asks for the current market price of aluminum sheets.

- <p>The price of aluminum sheets in the market can vary significantly based on factors such as grade, thickness, quantity, and market demand. As of my last update, the price per ton of aluminum was fluctuating around $2,000 to $3,000 USD, but this is subject to change. For the most accurate and up-to-date pricing, it's best to check with suppliers or commodity exchanges, as prices can shift daily due to global economic conditions and supply chain dynamics.</p>

- Q: What are the different cutting tools used for aluminum sheets?

- Aluminum sheets can be cut using various cutting tools available. Here are some options: 1. Circular Saw: To achieve a clean and smooth cut, it is essential to employ a circular saw with a carbide-tipped blade featuring fine teeth. 2. Jigsaw: For intricate cuts and curves, a jigsaw equipped with a metal-cutting blade is a suitable tool to cut aluminum sheets. 3. Bandsaw: When dealing with larger or thicker sheets, a bandsaw with a fine-toothed blade can provide a precise and straight cut. 4. Shears: Electric or manual shears are effective for straight cuts and ensuring a clean finish while cutting aluminum sheets. 5. Plasma Cutter: Thicker aluminum materials can be efficiently cut using a plasma cutter, which employs high-temperature plasma to melt through the metal, resulting in precise cuts. 6. Laser Cutter: For precise and intricate cuts, laser cutting machines are commonly utilized. They produce a high-powered laser beam that melts and vaporizes the aluminum sheet, allowing for accurate cuts. Remember to prioritize safety by wearing appropriate gear such as gloves and goggles when using any of these cutting tools. The choice of the tool should depend on the thickness of the aluminum sheet and the desired cut. It is advisable to seek professional advice or consult the manufacturer's guidelines for the specific tool being used.

- Q: Are 101 aluminum sheets suitable for medical equipment?

- Yes, 101 aluminum sheets are suitable for medical equipment.

- Q: Can aluminum sheets be used for food display cases?

- Yes, aluminum sheets can be used for food display cases. Aluminum is a popular choice for food display cases due to its exceptional strength, durability, and resistance to corrosion. Additionally, aluminum is lightweight, making it easier to handle and transport the display cases. Its clean, sleek appearance also enhances the presentation of the food items, making it an ideal material for showcasing various food products. Moreover, aluminum is non-toxic and does not react with food, ensuring the safety and hygiene of the displayed items. Overall, aluminum sheets are a suitable and practical choice for constructing food display cases.

- Q: What are the different types of alloys used in aluminum sheet?

- There are several different types of alloys used in aluminum sheet. Some of the most commonly used alloys include: 1. 3003 alloy: This alloy is known for its excellent resistance to corrosion and is often used in applications where exposure to moisture is a concern. It is also easy to form and weld, making it a popular choice for various structural components. 2. 5052 alloy: This alloy is highly corrosion-resistant and has good formability. It is often used in marine and automotive applications, as well as in architectural elements. 3. 6061 alloy: This alloy offers excellent strength and is commonly used in applications that require high structural integrity. It is often used in aerospace and marine industries, as well as in the construction of heavy-duty machinery. 4. 7075 alloy: This alloy is known for its high strength-to-weight ratio and is often used in aerospace and defense applications. It is also used in the manufacturing of bicycle frames, rock climbing equipment, and other high-performance applications. 5. 2024 alloy: This alloy is known for its high strength and excellent fatigue resistance. It is often used in aerospace applications, as well as in the production of structural components and fasteners. These are just a few examples of the many different types of alloys used in aluminum sheet. Each alloy has its own unique properties and advantages, making it suitable for specific applications and industries.

- Q: Aluminum siding is essentially maintenence-free, extremelydurable, and is a great insulator, even better than brick. Brickleaks air through the mortar between the bricks, especially in olderhouses that need tuckpointing. My question is, do you feel sidingstill has a declasse connotation, or is it getting more acceptableas the years go on?

- No worse than vinyl. The advantage vinyl has over aluminum is its resistance to denting. Siding is a good finish, but if you've already got a brick exterior, you're wasting the hard hours the masons put in to make it. If the brick has deteriorated or is horribly scarred, like having survived a hurricane or tornado, then sure, siding will spiff it up cosmetically as well as adding insulation value. That said, I'd rather take a house with aluminum siding over wood any day...and vinyl over that. If you get the siding in the color you want, as it's the entire thickness of the vinyl, powerwashing the outside won't take the color off as it could with painted wood or (though less likely) the finish on the aluminum...unless you *like* painting :)

- Q: i keep hearing all these things about burning aluminum foil and such

- Yes, it will not hold up and if the fire gets hot enough, it may melt. It is better to use rocks that do not come from a stream or any water area.

- Q: Yesterday I picked up an 1988 performance bike. I bought it for the parts. It rode really good and now I'm deciding to keep it as is but I'm wondering if the bike is safe to ride. I've hear of aluminum horror stories and I'm assuming old aluminum isn't asnymore safe.Should I toss the frame and put the parts on a steel frame I have or ride it and not worry about it failing.

- 1988? Why do you believe it is aluminum? So far as I can recall, Performance didn't begin offering bicycles AT ALL until about 1992. Even then they had steel frames... their bikes were supplied by a Taiwanese company by the name of UEC who also made (and makes) KHS brand bikes. Regarding early aluminum failures, yes, there were many simply because factories were unfamiliar with the material and thought they could get away without the post treatment that a welded aluminum structure often requires. Another reason for aluminum frame failure was when a few factories attempted to bond aluminum tubes to lugs. This is also a problem with carbon fiber bikes. This is because the epoxy used degasses, or hardens and becomes crystallized. The now brittle epoxy cracks and results in catastrophic failure. This, in the factory's opinion, was not a warranty event. I'll tell you what. Grab a magnet off of your refrigerator and see if it sticks to the frame. if it does- even a tiny bit- then it is steel. If the frame is WELDED aluminum it should be retired since there is no way of telling whether the frame was properly post-treated. If the frame is BONDED then it should be retired because of the possibility of the epoxy fracturing.

Send your message to us

Wholesale Sublimation Aluminum Sheets - Aluminium Composite Panel PE Good Price High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords