030 Aluminum Full Skin Sheets - Aluminium Sheet with BST Stocks Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

hot rolled and cold drawn and the best selling and mirror finish and checkered and several idfferent grades are all and aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series,6000 series,7000series, 8000 series, etc. The detailed grade are as1100, 2024, 3003, 3105, 5052,5754,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,O, H112, H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

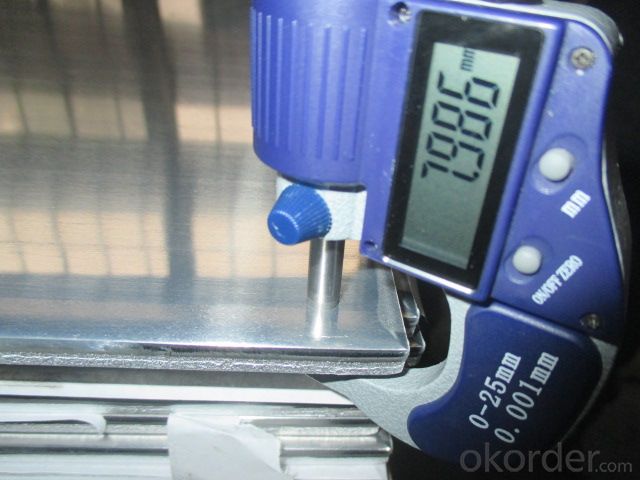

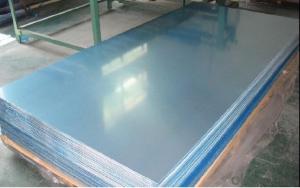

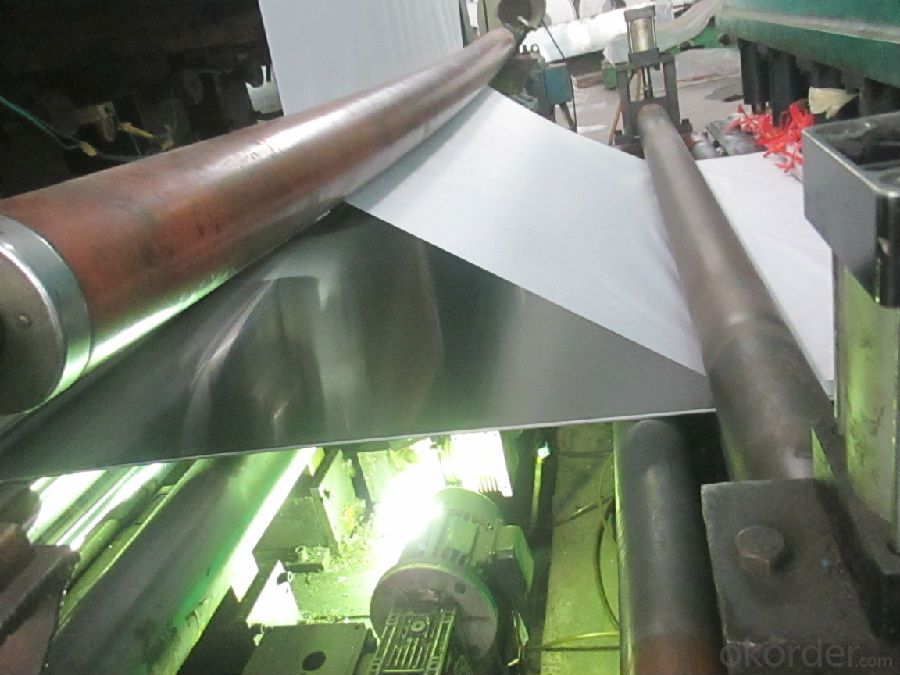

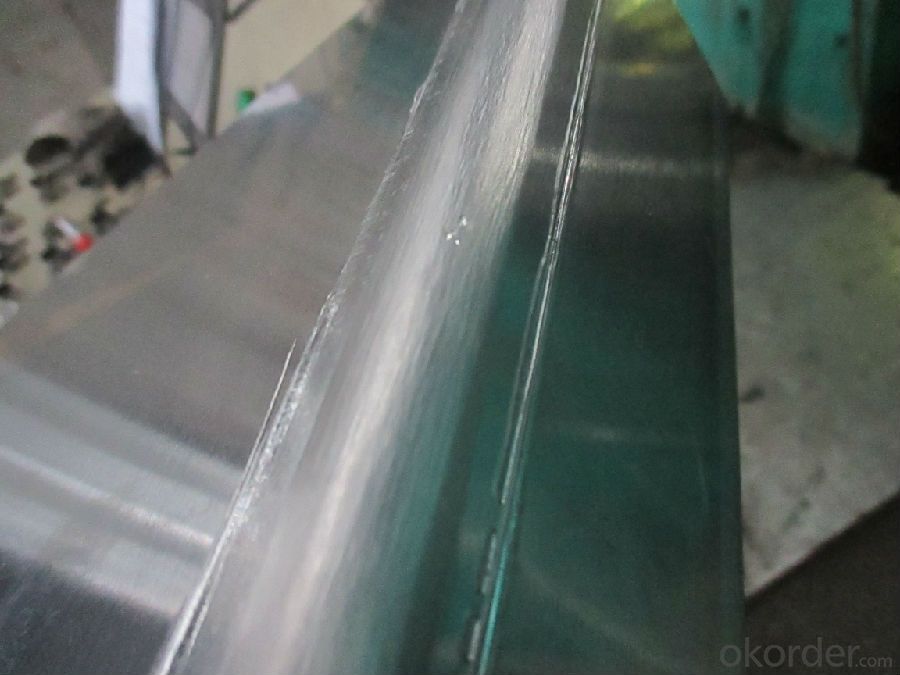

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 500mm to 2500mm, etc.

What is the length range:

---It is from 1000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 2 tons/each size.

How many tons did you export in one year?

---Normally it is around 6000 tons totally.

Where is your client from?

---Normally it is from UAE, FIJI,Arabia, England,Turkey,etc.

What is your mainly products?

---Normally they are aluminum sheet,and big-5-bar aluminium checkered sheet,small-5-bar aluminium checkered sheet, and the best-selling ,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What specific considerations or precautions should be taken into account when using aluminum sheets in environments with high moisture levels?

- <p>When using aluminum sheets in damp or wet environments, it's important to consider the potential for corrosion. While aluminum is generally corrosion-resistant due to its protective oxide layer, it can still be susceptible to certain types of corrosion in the presence of moisture, especially if the environment is acidic or saline. It's crucial to use high-quality aluminum alloys that are designed for such conditions. Additionally, proper surface treatment such as anodizing or applying protective coatings can enhance resistance to corrosion. Regular inspections and maintenance are also recommended to check for signs of corrosion and to address any issues promptly.</p>

- Q: Are aluminum sheets suitable for use in food processing or storage?

- Aluminum sheets are highly suitable for use in food processing or storage. This metal is non-toxic, resistant to corrosion, and possesses exceptional thermal conductivity. These characteristics make it an ideal material for various food applications. Aluminum sheets are commonly utilized in the production of food and beverage cans, foil wraps, trays, and containers. In terms of food preservation, aluminum is impermeable to oxygen, light, moisture, and microorganisms. This quality ensures that the quality and freshness of food products are safeguarded. Additionally, it prevents the transfer of flavors, odors, and contaminants. Moreover, aluminum's lightweight and manageable nature make it convenient for packaging and transporting food items. Furthermore, aluminum sheets are hygienic and easy to clean, which is crucial in food processing and storage settings where cleanliness is of utmost importance. They can be easily sterilized and do not retain any bacteria or food particles that may lead to contamination. In conclusion, aluminum sheets are an excellent choice for food processing and storage due to their non-toxic nature, resistance to corrosion, excellent thermal conductivity, impermeability to oxygen and moisture, ability to preserve food quality, and hygienic properties.

- Q: Can aluminum sheets be used for electrical wiring?

- Electrical wiring cannot utilize aluminum sheets. Although aluminum boasts good conductivity, its high electrical resistance renders it unsuitable for such purposes. Copper, on the other hand, is the preferred material for electrical wiring due to its low resistance and superior efficiency in conducting electricity. Moreover, aluminum is susceptible to oxidation, which may result in inadequate conductivity and potential fire risks. Copper wires, on the contrary, are meticulously crafted and produced to comply with electrical safety standards, guaranteeing dependable and secure electrical connections.

- Q: Are the aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction due to their excellent corrosion resistance, high strength-to-weight ratio, and durability in harsh marine environments.

- Q: What are the different joining methods for aluminum sheets?

- There are several joining methods for aluminum sheets, including welding, adhesive bonding, mechanical fastening, and soldering.

- Q: Are aluminum sheets suitable for signage and advertising?

- Yes, aluminum sheets are highly suitable for signage and advertising purposes. Aluminum is a durable and lightweight material, making it ideal for creating signs that can withstand outdoor weather conditions and transportation. Its resistance to rust and corrosion ensures that the signs will maintain their appearance and functionality over time. Aluminum sheets can be easily cut and shaped into various sizes and designs, making them versatile for different advertising needs. Additionally, aluminum's smooth surface allows for high-quality printing and graphics, providing excellent visibility and readability for signage. Overall, with its durability, versatility, and aesthetic appeal, aluminum sheets are a practical and effective choice for signage and advertising.

- Q: What are the primary components that make up aluminum sheets?

- <p>Aluminum sheets are primarily composed of aluminum, which is a lightweight and malleable metal. They are made from pure aluminum or aluminum alloys, which may include small percentages of other elements to enhance specific properties such as strength, corrosion resistance, or workability. Common alloying elements include copper, magnesium, manganese, silicon, and zinc. The exact composition varies depending on the specific grade of aluminum and its intended use. Pure aluminum is soft and not commonly used for sheets; instead, alloys are preferred for their improved strength and durability.</p>

- Q: If Aluminum can, in fact, not be sterilized I would love to know why.

- Sterilization refers to the ability to clean a surface of bacterium. Simply pouring rubbing alcohol on something sterilizes it. Aluminum can be sterilized just as good as any other metal. If it couldn't, would we ship our favorite drinks in cans of it?

- Q: I saw a guy on ebay take a washed out paint can fill it full of lighted charcoal bricks and a tin can in the middle. He was melting aluminum cans in there then pured it into a mold. Does this really work and does anyone have any good ideas on how else to do this?

- Aluminum alloys melt at around 1200 degrees, aluminum cans maybe somewhat lower, but I doubt a tin can would hold up long enough to melt much aluminum, and you would need to be very careful, any moisture in your mold will cause the aluminum to literally explode back into your face. I am not saying it couldn't be done, but you really would need lots of safety equipment before trying it.

- Q: This question asks for signs or indicators that would suggest whether a roof needs to be replaced or repaired using aluminum sheets.

- <p>To determine if your roof needs replacement or repair with aluminum sheets, look for the following signs: visible rust or corrosion, especially on the seams and fasteners; sagging or buckling in the roof surface; leaks or water damage inside your home; and excessive noise during rain or wind. If the damage is widespread or the roof is old, replacement might be necessary. However, if the damage is limited to specific areas, repairs could suffice. It's always best to consult with a professional roofer for an accurate assessment.</p>

Send your message to us

030 Aluminum Full Skin Sheets - Aluminium Sheet with BST Stocks Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords