Brushed Anodized Thin Aluminum Alloy Sheets for Foil Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Thin Aluminum Alloy Sheets used for Foil Stock

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Thin Aluminum Alloy Sheets used for Foil Stock

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Thin Aluminum Alloy Sheets used for Foil Stock

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

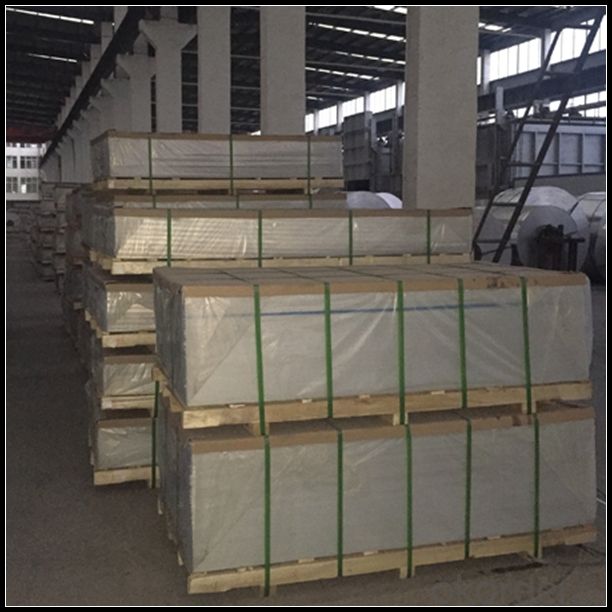

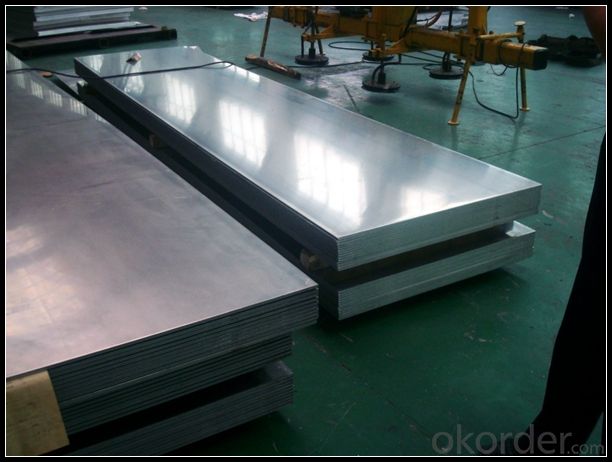

5. Image of Thin Aluminum Alloy Sheets used for Foil Stock

6. Package and shipping of Thin Aluminum Alloy Sheets used for Foil Stock

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: what are the differences between aluminium , iron , steel.... properties like strength , durability , corrosion resistance properties...finally which is cost efficient and best for all purpose..??

- steel okorder /

- Q: Are aluminum sheets suitable for aerospace engine components?

- Aerospace engine components can indeed be made from aluminum sheets. Aluminum is widely employed in the aerospace industry because of its advantageous properties. Its lightweight nature is crucial for aircraft and spacecraft applications, as it aids in reducing overall weight and fuel consumption. Furthermore, aluminum possesses outstanding thermal conductivity, enabling efficient heat dissipation generated by the engine. This characteristic is essential for maintaining optimal operating temperatures. Additionally, aluminum exhibits a commendable strength-to-weight ratio, corrosion resistance, and ease of fabrication. These qualities make it suitable for various engine components like casings, housings, and structural elements. Nevertheless, it is important to note that not all engine components can be solely constructed using aluminum sheets. Certain parts may require higher strength materials or specific alloys to withstand extreme temperatures or stresses. Overall, aluminum sheets have proven to be a reliable and frequently employed material for aerospace engine components. They significantly contribute to the overall performance and efficiency of aerospace engines.

- Q: Can aluminum sheets be used for reflective purposes?

- Yes, aluminum sheets can be used for reflective purposes due to their high reflectivity and low absorption of light.

- Q: Are aluminum sheets suitable for food contact applications?

- Aluminum sheets are indeed appropriate for food contact purposes. The food industry extensively employs aluminum because of its diverse advantageous characteristics. It is non-hazardous, non-responsive, and resistant to corrosion, thereby ensuring that it is safe to use alongside food. Aluminum sheets can be effortlessly molded into various shapes and sizes, rendering them suitable for a broad array of food packaging and cooking uses. Moreover, aluminum boasts exceptional thermal conductivity, facilitating efficient heat transfer during the cooking or baking process. It is also impervious to light, moisture, and oxygen, creating a protective barrier that preserves the freshness and quality of food. In general, due to their safety, adaptability, and durability, aluminum sheets are a highly favored option for food contact applications.

- Q: Can 101 aluminum sheets be purchased in small quantities or only in bulk?

- Aluminum sheets can typically be purchased in both small quantities and bulk, depending on the supplier and their policies. It is advisable to check with the specific supplier to determine the availability of purchasing 101 aluminum sheets in small quantities.

- Q: Can aluminum sheets be used for architectural applications?

- Yes, aluminum sheets can definitely be used for architectural applications. Aluminum is a versatile and lightweight material that offers numerous advantages for architectural projects. Its durability, corrosion resistance, and ability to withstand extreme weather conditions make it ideal for various architectural applications such as roofing, cladding, facades, windows, doors, and decorative elements. Aluminum sheets are available in a wide range of thicknesses, finishes, and colors, allowing architects and designers to achieve their desired aesthetic while maintaining structural integrity. The material can be easily shaped, bent, and formed into complex designs, providing flexibility and creative freedom to architects. In addition to its aesthetic appeal, aluminum is also a sustainable choice for architectural applications. It is a highly recyclable material, with a high recycling rate, making it an environmentally friendly option. Using aluminum sheets in architectural projects can contribute to reducing the carbon footprint and promoting sustainable design practices. Furthermore, aluminum sheets offer excellent thermal and acoustic properties, contributing to energy efficiency and sound insulation in buildings. The material can help reduce energy consumption and enhance occupant comfort, making it an attractive choice for architects and building owners. Overall, aluminum sheets are a popular choice in architectural applications due to their versatility, durability, sustainability, and aesthetic appeal. They offer numerous benefits and can be used in various ways to create stunning architectural designs while ensuring long-lasting performance.

- Q: How thick are aluminum sheets commonly available?

- Aluminum sheets commonly come in various thicknesses, depending on the intended use and application. The most commonly available aluminum sheet thicknesses range from 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). However, thinner and thicker aluminum sheets are also available, with some going as thin as 0.016 inches (0.4 mm) and others as thick as 0.25 inches (6.35 mm) or more. The specific thickness required will depend on the specific project or industry application.

- Q: What are the common surface finishes for aluminum sheets?

- Aluminum sheets can be finished in various ways, including mill finish, brushed finish, anodized finish, and powder-coated finish. The mill finish refers to the untreated surface of the aluminum sheet, which has a slightly rough texture and may show imperfections. It is a basic and cost-effective option, often used in industrial applications or as a base for further finishing processes. For a textured appearance and to conceal minor scratches or imperfections, the brushed finish involves a mechanical brushing process that creates fine parallel lines on the aluminum sheet's surface. The anodized finish is achieved through an electrochemical process called anodization, which forms a protective oxide layer on the aluminum's surface. This finish enhances its corrosion resistance and durability, and it also offers a range of color options. Anodized aluminum sheets are commonly used in architecture or for decorative purposes. In the powder-coated finish, a dry powder is applied to the aluminum sheet's surface and then baked at high temperatures. This creates a durable and attractive finish that is resistant to chipping, scratching, and fading. Powder-coated aluminum sheets are often used outdoors in applications such as building facades, signage, or automotive parts. Ultimately, the choice of surface finish for aluminum sheets depends on the desired appearance, functionality, and specific requirements of the application.

- Q: Are the aluminum sheets suitable for decorative purposes?

- Yes, aluminum sheets are suitable for decorative purposes. They offer a sleek and modern look, are lightweight, durable, and versatile, making them an ideal choice for various decorative applications such as wall panels, signage, ceilings, and furniture. Additionally, aluminum sheets can be easily customized, painted, or engraved to create unique and visually appealing designs.

- Q: I am trying to find a BRUSH ON type glue to adhere aluminium foil to a plastic model. scotch super 77 works great but dries way to fast and blows small pieces all over. white glue just dont work and superglue eats the plastic. I could use some help

- white glue will work if you dilute it 50% with water... they also sell an adhesive in craft stores for gluing down gold leaf... and of course Bare-Metal sells foil with an adhesive backing.... at one time they also sold a foil adhesive...

Send your message to us

Brushed Anodized Thin Aluminum Alloy Sheets for Foil Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords