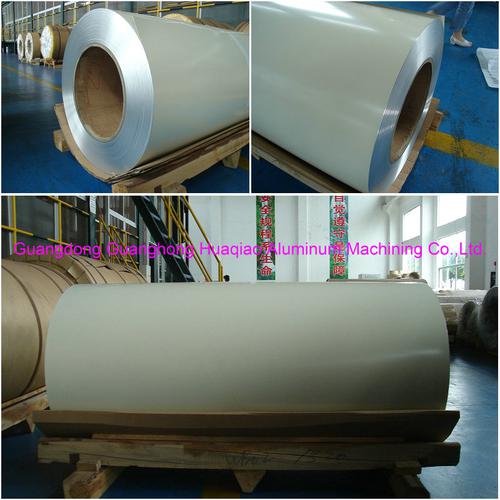

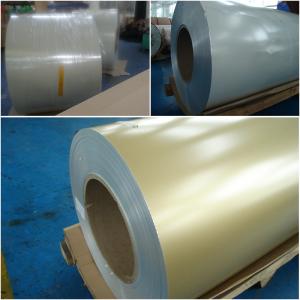

Aluminum Coil Stock - PE Prepainted Aluminum Coil Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PE彩涂铝卷产品是采用聚酯涂料经专业辊涂烘烤加工而成。色泽靓丽,颜色多样,选择方便;色差小,耐冲击、易加工,各项性能均达到或超过国家相关标准。产品广泛用于室内及门面装修,天花扣板、屋面瓦、墙板、广告招牌、柜台、家电家具、车体游船等内外装饰。

技术参数

铝材厚度 | 涂干膜厚度 | MEK | T弯 | 冲击 | 附着力 | 铅笔硬度 | 耐沸水 |

>0.3mm | ≥18±1um | ≥100次 | ≤3T | 50kg.cm | 0级 | ≥HB | 2h无变化 |

0.2~0.3mm | ≥18±1um | ≥100次 | ≤3T | 20kg.cm | 0级 | ≥HB | 2h无变化 |

0.15~0.18mm | ≥15±1um | ≥80次 | ≤4T | 20kg.cm | ≤1级 | ≥HB | 1h无变化 |

0.08~0.12mm | ≥15±1um | ≥80次 | ≤4T | 10kg.cm | ≤1级 | ≥HB | 1h无变化 |

0.026~0.06mm | ≥12±1um | ≥50次 |

| 10kg.cm | ≤1级 | ≥HB | 1h无变化 |

PE Aluminum Coating Coils for ACP

Features of PE Aluminum Sheet:

1. Adopting precision rolling coatingtechnology, our PVDF and PE coated coil can ensure excellent adhesive withoutcoating omission.

2. For the PE coated aluminum coil weproduced, there are various colors for your choice.

3. Using infrared heating technology toprotect environment from pollution.

4. Our coated aluminum coil has four-rollercoating line, uniform coating thickness and good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wall panels, advertisement boards, counters,home appliances, decoration in and out of autos and boats.

Performance of the coating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: What is the maximum coil weight for aluminum coils?

- The maximum weight of aluminum coils can differ due to several factors including coil thickness, width, and the specific alloy employed. Typically, the maximum weight for aluminum coils falls within the range of 5,000 to 25,000 pounds. Nevertheless, it is crucial to acknowledge that these figures are only approximate and may vary based on the manufacturer's guidelines and the capabilities of the equipment. Moreover, it is advisable to consult the manufacturer or supplier in order to ascertain the specific limitations on coil weight to guarantee safe handling and transportation.

- Q: Explain the differences between aluminum coil and aluminum sheet in a few sentences.

- <p>Aluminum coil and aluminum sheet are both flat aluminum products but differ in form and usage. Aluminum coil is a long, continuous roll of aluminum that can be easily unrolled and cut to length, making it ideal for manufacturing processes where the material needs to be fed through machines. It is commonly used in industries such as construction, packaging, and automotive for applications like roofing, siding, and food packaging. Aluminum sheet, on the other hand, comes in flat, rectangular pieces with specific dimensions and is typically thicker than coil. It is used in applications where a solid, non-continuous piece is required, such as in signage, furniture, and decorative elements. The thickness and surface finish can also vary between coils and sheets, with sheets often being available in a wider range of finishes and thicknesses.</p>

- Q: Is it possible to use an aluminum coil as a paperweight for holding down papers?

- <p>Yes, you can use an aluminum coil as a paperweight. Aluminum is a lightweight and sturdy metal that can effectively hold down papers on a desk. Its weight and shape make it suitable for this purpose. However, ensure the coil is clean and smooth to avoid any damage to the papers or surfaces it comes into contact with. Additionally, consider the size and thickness of the coil to ensure it provides enough weight to keep your papers in place.</p>

- Q: What are the common alloys used in aluminum coil production?

- The common alloys used in aluminum coil production are 3003, 3105, 5052, and 6061.

- Q: What are the different coil packaging sizes available for aluminum coils?

- The customer's specific needs and requirements determine the available packaging sizes for aluminum coils. However, standard coil packaging sizes are generally found in the market. These sizes vary in dimensions and weights, ranging from small to large. Various common coil packaging sizes for aluminum coils include: 1. Small coils: These serve smaller applications or projects and typically have a diameter of 200-300mm and a weight of 50-150kg. 2. Medium coils: Suitable for medium-sized applications and projects, these coils usually have a diameter of 300-600mm and a weight of 150-500kg. 3. Large coils: Designed for larger applications or projects requiring a substantial amount of aluminum, these coils typically have a diameter of 600-1200mm and a weight of 500-2000kg. It's important to note that these are general guidelines, and the actual coil packaging sizes may vary depending on the manufacturer and specific customer requirements. Moreover, unique project needs often allow for the request of custom packaging sizes.

- Q: How much does it cost to use fluorocarbon paint for aluminum coil roller coating?

- Fluorocarbon paint can be divided into fluorocarbon paint for exterior wall, aluminum fluorocarbon paint, metal fluorocarbon paint and steel structure fluorocarbon paint according to usages. It can also be divided into national standard product and non-national standard product according to industrial standards.

- Q: Are aluminum coils easy to install?

- Aluminum coils, in general, prove to be easily installed. Their lightweight and flexibility contribute to their manageable handling and maneuverability during installation. They can be effortlessly cut and molded to suit the precise installation requirements. Moreover, they are frequently obtainable in pre-cut dimensions, further streamlining the installation procedure. Additionally, aluminum coils usually incorporate interlocking edges or snap-on connectors, facilitating the connection of multiple coils or other components. All in all, with appropriate tools and fundamental HVAC installation knowledge, aluminum coils can be readily installed.

- Q: Can aluminum coils be used in heat exchanger fins?

- Yes, aluminum coils can be used in heat exchanger fins. Aluminum is a popular choice for heat exchangers due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. The use of aluminum coils in heat exchanger fins allows for efficient transfer of heat between two fluids, making it an ideal material for this application. Additionally, aluminum coils can be easily formed into various fin shapes, providing flexibility in design and maximizing the surface area for heat transfer. Overall, aluminum coils are commonly used in heat exchanger fins to enhance heat transfer efficiency and improve the overall performance of the heat exchanger system.

- Q: How do aluminum coils contribute to thermal insulation in buildings?

- There are several ways in which aluminum coils contribute to thermal insulation in buildings. Firstly, due to its excellent heat conductivity, aluminum can effectively transfer heat away from the building's interior. This allows for efficient cooling during hot summer months, as the aluminum coils can absorb and release the heat, preventing it from entering the building. Secondly, aluminum coils can be integrated into HVAC systems to control the temperature inside the building. By circulating cool air through the coils, the aluminum helps maintain a comfortable temperature, reducing the need for excessive energy consumption. Additionally, aluminum coils can be used as part of a radiant barrier insulation system. This involves placing reflective aluminum foil on the inside of walls, roofs, or attics, which reflects radiant heat back towards its source. This prevents heat transfer into the building, keeping it cooler in the summer and reducing the need for air conditioning. Moreover, aluminum coils are lightweight and easy to install, making them a cost-effective choice for thermal insulation in buildings. They can be easily shaped and fitted into various spaces, ensuring optimal coverage and maximum thermal efficiency. In conclusion, aluminum coils are essential for thermal insulation as they effectively dissipate heat, regulate temperature, and reflect radiant heat. Their versatility and efficiency make them a valuable component in creating energy-efficient and comfortable environments within buildings.

- Q: How are aluminum coils used in the manufacturing of signage?

- Due to their numerous advantageous properties, aluminum coils find extensive use in the production of signage. These coils are commonly crafted from high-quality aluminum alloy, which offers exceptional resistance to corrosion and durability, making them an ideal choice for outdoor applications. The initial step in utilizing aluminum coils for signage manufacturing involves the process of coil slitting. This process entails cutting the large aluminum coils into smaller, more manageable sizes that can be effortlessly shaped and formed to meet specific design requisites. By undergoing this slitting process, the coils are ensured to possess the appropriate width and thickness for the desired signage application. Once the coils are suitably sized, they are typically fed into a roll-forming machine. This machine enables the precise shaping of the aluminum coils into the desired signage profiles, such as flat panels, letters, or channel letters. The adaptability of aluminum permits the creation of intricate and personalized designs with ease. Aluminum provides great versatility when it comes to finishing options. The coils can be coated with various protective finishes, such as polyester or PVDF coatings, which bestow enhanced durability and resistance to fading, chipping, or peeling. Additionally, these finishes offer a broad spectrum of color choices, allowing signage manufacturers to fabricate visually captivating and vibrant displays. Furthermore, aluminum coils possess the advantage of being lightweight, thereby facilitating ease of handling during the fabrication process and reducing transportation costs. The lightweight nature of these coils also renders them suitable for mounting on diverse surfaces, including walls, poles, or freestanding structures. To summarize, aluminum coils play an indispensable role in the manufacturing of signage by providing a lightweight, versatile, corrosion-resistant, and durable material. Their ability to be effortlessly shaped and formed enables the creation of tailor-made designs, and their protective finishes guarantee signage displays that are long-lasting and visually striking.

Send your message to us

Aluminum Coil Stock - PE Prepainted Aluminum Coil Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords