Aluminum Sublimation Sheets for Building Construction Decoration Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Building Contruction Decoration Material Aluminium Plate Description:

Building Contruction Decoration Material Aluminium Plate are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Building Contruction Decoration Material Aluminium Plate:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

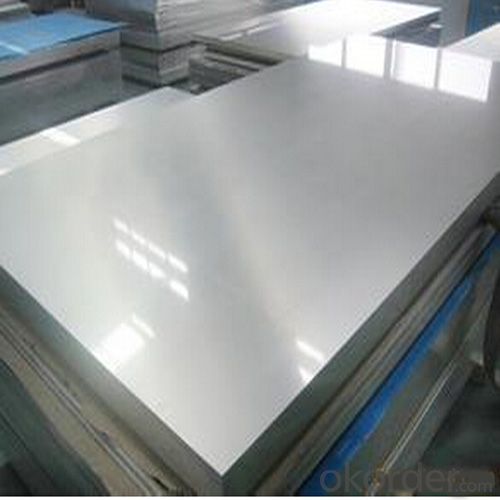

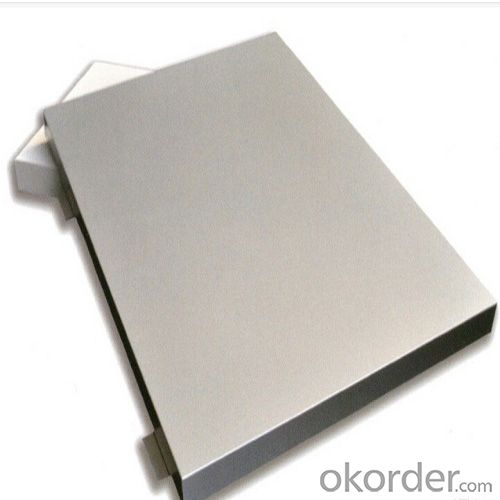

3.Building Contruction Decoration Material Aluminium Plate Images:

4. Building Contruction Decoration Material Aluminium Plate Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: How to distinguish aluminum sheet from magnesium sheet?

- put two sheets into excess NaOH. The one that reacts with NaOH, generating sediment, is magnesium sheet,(sediment, but Al(OH)3 is amphoteric:Mg(OH)2) another one without sediment is aluminum sheet(in fact, there is sediment Al(OH)3, but it will react with alkali,)

- Q: Are aluminum sheets prone to warping?

- Under certain conditions, aluminum sheets may be susceptible to warping. Unlike steel, aluminum is a relatively soft metal, making it more prone to bending or distorting. However, the extent of warping in aluminum sheets depends on various factors, including sheet thickness, alloy composition, temperature exposure, and applied stress levels. Thinner aluminum sheets have less structural integrity, making them more prone to warping. Conversely, thicker sheets are more resistant to warping due to their increased rigidity. The specific alloy composition of the aluminum sheet also affects its susceptibility to warping. Warping can occur due to temperature fluctuations. High temperatures cause aluminum to expand, and without proper support, it may bend or warp. Similarly, rapid cooling causes contraction, leading to warping. The level of stress applied to aluminum sheets can contribute to warping. Excessive bending, pressure, or unevenly distributed loads can deform the sheet. To minimize warping, it is crucial to handle aluminum sheets carefully, provide adequate support during temperature changes, and avoid applying excessive stress. Additionally, using thicker sheets or selecting alloys with higher tensile strength helps reduce the risk of warping.

- Q: What is the cost of aluminum sheet compared to other metals?

- The cost of aluminum sheet is generally lower compared to other metals such as steel or titanium.

- Q: What are the different machining options for aluminum sheets?

- There are several different machining options available for aluminum sheets, depending on the desired outcome and the specific requirements of the project. Some of the most common machining options for aluminum sheets include: 1. Cutting: Aluminum sheets can be cut using various methods such as shearing, sawing, or laser cutting. Shearing involves using a shearing machine to apply a high force to the sheet, resulting in a clean and straight cut. Sawing, on the other hand, utilizes a saw blade to cut through the aluminum sheet. Laser cutting uses a high-powered laser beam to melt or vaporize the aluminum, resulting in a precise and accurate cut. 2. Drilling: Drilling is a common machining option used to create holes in aluminum sheets. This process involves using a drill bit to remove material from the sheet, creating a hole with the desired diameter. Different drill bits can be used to achieve specific hole sizes and shapes. 3. Milling: Milling is a versatile machining option that can be used to create complex shapes and contours in aluminum sheets. This process involves using a rotating cutting tool to remove material from the sheet, resulting in a precise and accurate finish. Milling can be done using various types of milling machines, such as vertical milling machines or CNC milling machines, depending on the complexity of the project. 4. Turning: Turning is another machining option used for aluminum sheets, especially when creating cylindrical or conical shapes. This process involves rotating the aluminum sheet against a cutting tool, which removes material and shapes the sheet to the desired dimensions. Turning can be done on manual lathes or CNC turning machines, depending on the level of precision required. 5. Bending: Bending is a common machining option used to create curved or angled shapes in aluminum sheets. This process involves applying force to the sheet, causing it to deform and take on the desired shape. Bending can be done manually using tools like a brake press, or it can be done using hydraulic or CNC press brakes for more precise and consistent results. These are just a few of the different machining options available for aluminum sheets. The choice of machining method will depend on factors such as the desired outcome, the complexity of the project, and the resources available. It is important to select the most suitable machining option to achieve the desired results efficiently and effectively.

- Q: How is the thickness of an aluminum sheet measured?

- The thickness of an aluminum sheet can be measured using various methods. One common technique is to use a micrometer or caliper, which are precision measuring tools. The micrometer is placed on one end of the sheet and slowly closed until it touches the other end, providing an accurate measurement of the thickness. This method is effective for measuring thin aluminum sheets. For thicker sheets, a thickness gauge can be used. It consists of a small handheld device with a probe that is pressed against the sheet's surface. The gauge then displays the thickness reading on a screen. This method is especially useful for measuring thicker sheets where a micrometer or caliper may not be suitable. Another way to measure the thickness of an aluminum sheet is by using an ultrasonic thickness gauge. This tool emits ultrasonic waves from a transducer, which are then reflected back from the sheet's surface. By calculating the time taken for the waves to travel and return, the gauge can determine the thickness of the sheet with high accuracy. This method is particularly effective for measuring the thickness of large or irregularly shaped aluminum sheets. In summary, the thickness of an aluminum sheet can be measured using various tools such as a micrometer, caliper, thickness gauge, or ultrasonic thickness gauge, depending on the thickness and size of the sheet.

- Q: And isn't aluminum extremely bad for ones health?

- it's okorder

- Q: How to mix solid aluminium sheet with solid copper sheet (using heat?) to make a compound.

- Aluminium and copper can be used to produce an alloy (see the first link, under wrought alloys). The alloy strength is comparable to steel. Aluminium melts at around 660C and copper at 1084C, so you'd need special burners to produce that kind of heat. An oxyacetylene torch would do it, but more readily available gases like propane and butane mixed with air would also suffice.

- Q: What is the thickness range available for 101 aluminum sheets?

- The thickness of 101 aluminum sheets can differ depending on the manufacturer and supplier. Typically, these sheets come in various thicknesses, ranging from 0.016 inches (0.41 mm) to 0.25 inches (6.35 mm). It is crucial to mention that this range does not encompass all possibilities, as there might be alternative thickness options or customizable choices depending on specific needs or preferences.

- Q: What type of aluminum plate does the traffic sign use? 1100?

- Formulated according to unused specifications and design requirements. May refer to the road traffic sign and the marking establishment standard execution.

- Q: Are 101 aluminum sheets resistant to UV radiation?

- Yes, 101 aluminum sheets are generally resistant to UV radiation. Aluminum naturally forms a thin oxide layer on its surface, which acts as a protective barrier against UV rays. This oxide layer helps to prevent the aluminum from corroding or degrading when exposed to sunlight. However, it is important to note that prolonged exposure to intense UV radiation can still cause some discoloration or fading over time. Therefore, if the aluminum sheets will be continuously exposed to direct sunlight for extended periods, it may be advisable to apply a protective coating or use a specialized UV-resistant paint to further enhance their resistance to UV radiation.

Send your message to us

Aluminum Sublimation Sheets for Building Construction Decoration Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords