Color Aluminum Sheets with Better Stocks Price in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

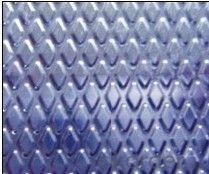

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1500mm*3000mm,at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 100mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 15 tons/each size.

How many tons did you export in one year

USA,USA,CANADA,BANGLADESH,FIJI,ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Can aluminum sheets be used in aerospace industries?

- Yes, aluminum sheets are commonly used in aerospace industries. Aluminum is a lightweight and corrosion-resistant material that possesses excellent strength-to-weight ratio, making it ideal for various aerospace applications. It is used in the construction of aircraft structures, such as wings, fuselage, and landing gear, due to its ability to withstand high stress and pressure. Additionally, aluminum sheets are easily formable and can be fabricated into complex shapes, contributing to the design flexibility required in the aerospace industry. However, it is important to note that aluminum alloys are typically used in aerospace applications rather than pure aluminum, as they offer enhanced mechanical properties and improved performance.

- Q: This question asks for methods to prevent aluminum sheets from warping or curling during processing or storage.

- <p>To prevent aluminum sheets from warping or curling, ensure proper storage by keeping them flat and avoiding stacking them under heavy loads. Maintain a controlled environment with consistent temperature and humidity to prevent expansion and contraction. When cutting, use sharp tools to minimize heat generation and stress. Apply a stress-relieving process after fabrication to reduce internal stresses. Use appropriate jigs and fixtures during fabrication to maintain flatness. Finally, consider the thickness and alloy of the aluminum sheet, as some are more prone to warping than others.</p>

- Q: This question asks if aluminum sheets are appropriate for use in regions with cold temperatures.

- <p>Aluminum sheets are generally suitable for use in cold climates. They have excellent resistance to corrosion and maintain their structural integrity in low temperatures. However, aluminum is a good conductor of heat, so it can be prone to heat loss if not properly insulated. For outdoor applications in cold climates, it's important to ensure that aluminum structures are well-insulated to prevent heat transfer. Additionally, aluminum's malleability can make it susceptible to denting or damage from ice and snow, so protective measures may be necessary.</p>

- Q: Are aluminum sheets suitable for signage?

- Signage can greatly benefit from the use of aluminum sheets. This material is known for its versatility and numerous advantages when it comes to signage applications. With its lightweight nature, durability, and resistance to corrosion, aluminum is an excellent choice for both indoor and outdoor signage. Regardless of weather conditions, be it rain, snow, or intense UV exposure, aluminum sheets will not deteriorate or fade. Furthermore, aluminum sheets are easy to work with, providing a wide range of customization options such as embossing, engraving, and digital printing. Not only are they cost-effective, but they also have a long lifespan, ensuring that signage remains in top-notch condition for extended periods. Ultimately, due to their durability, versatility, and aesthetic appeal, aluminum sheets are a preferred choice for signage.

- Q: Does anyone know anything about the value of aluminum can(beer, soda, etc.) pull tabs? I have heard a rumor that the tabs are worth more than the cans and that a gallon jug of tabs can be sold at recycling centers for several hundred dollars.Anyone know if this is really true?

- Sept 2014 Update. Aluminum recycle rates continue to be low in comparison to other metals, about 85 cents per pound. 2,000 tabs are worth about $1. A gallon (approximately 4,000 tabs) is worth about $2. The effort needed to collect that many tabs isn't well rewarded. There is no special value for the pull tab - it is simply aluminum. The entire can has more than 100 times the aluminum as the tab itself. While it takes less room, recycling just the tab and throwing away the can doesn't make any sense and isn't worth the time or effort. While they are accepted at charities like the Ronald McDonald House, you are likely to spend more on gas driving them there and would pay approximately twenty times their value in postage if you mail them. Some craft projects use tabs, if you find someone or a group who does this they may give you more than the metal value. Purses made out of pull tabs are somewhat popular. My suggestion - if you recycle - great! Recycle the whole can and realize that you are not going to get yourself or a charity rich because aluminum isn't worth a lot. You are helping the environment though. Take the entire can and any other metal you want to recycle to a local recycler and donate the proceeds however you wish.

- Q: I can't seem to find what uses or contains Aluminum Nitride. Help!

- Don't know where you looked, but this came up with very basic web search. Metallization methods are available to allow Aluminium nitride to be used in electronics applications similar to those of alumina and beryllium oxide. Among the applications of Aluminium nitride are opto-electronics, dielectric layers in optical storage media, electronic substrates, chip carriers where high thermal conductivity is essential, military applications, as a crucible to grow crystals of gallium arsenide, steel and semiconductor manufacturing. Epitaxially grown thin film crystalline aluminium nitride is also used for surface acoustic wave sensors (SAW's) deposited on silicon wafers because of the Aluminium nitride's piezoelectric properties. One application is an RF filter used in mobile phones called a thin film bulk acoustic resonator (FBAR). This is a MEMS device that uses aluminium nitride sandwiched between two metal layers.

- Q: Can aluminum sheet be used for architectural applications?

- Aluminum sheet is indeed suitable for architectural purposes, thanks to its impressive strength, durability, and resistance to corrosion. It is widely utilized in the construction field for various architectural applications such as cladding, roofing, and facades. Architects and designers can select aluminum sheets in different thicknesses to meet their specific aesthetic and functional requirements. These sheets can be easily shaped, bent, and formed to create distinctive architectural elements like panels, screens, louvers, and decorative features. Moreover, aluminum sheets can be coated or finished to enhance their appearance and protect them from environmental factors. Techniques such as anodizing, powder coating, or painting can be employed to improve the material's resilience against weathering, UV radiation, and pollution. Due to its lightweight nature, aluminum is favored for architectural applications as it reduces the overall weight of the structure and facilitates convenient installation. Additionally, aluminum is an environmentally friendly option for architectural projects as it can be recycled infinitely, thus promoting sustainability. To summarize, aluminum sheets are a highly viable and popular choice for architectural purposes because of their strength, versatility, durability, and aesthetic appeal.

- Q: im wanting to try and source my own chemicals for experiments and such in the cheapest way possiblei thought a cheap method of making powdered aluminium would be to just sandpaper aluminium kitchen foil and collect the powder, what i need to know is:how pure is aluminium foil?.....e.g is it actually mixed with some other metals and is an alloyand will the powder i collect be as good as bottled aluminium powder? i know it wont be perfect but as long as its similar that should be fineim using it for pyrotechnical experiments by the way

- Aluminum foil is pretty pure for most purposes (99.1 % pure). However, I really think sandpapering aluminum foil is not your best option. For one, aluminum foil is quite expensive, I wonder if you could just get a bunch of the powder for a cheaper price than buying an equal mass of aluminum foil. Also, how would you even begin sandpapering it? If you rub a crumpled up ball of aluminum on a rough surface, you don't get a powder, you just get a ripped up ball and a gray mark on the rough surface. But you could try, tell me if it works. However, I think you may have better odds with aluminum cans. They are cheaper and thicker thus not so prone to ripping. Although I still doubt you could get a reasonable quantity of aluminum powder from that. If all else fails, you could always try stuffing a bunch of aluminum foil in a blender.

- Q: i added aluminum sulfate to the soil from the bag with out mixing it with water and my hydrangeas look very sad. It burned them i guess... What is best thing to do to take some of it out or all if i can? will adding large amounts of water to the soil help it clear or will it make it worse? please before they die!!!10points!!!

- how much did you add i mix it with the soil for my hydrangeas and never have a problem.. blend it into the soil around the hydrangeas the burning you see may be related to something other than the aluminum sulfate

- Q: This question asks for the various types of adhesives that can be used for bonding aluminum profiles when constructing exterior cladding.

- <p>For bonding aluminum profiles in exterior cladding, several types of adhesives are commonly used. These include: 1. Structural adhesives, which provide strong and durable bonds suitable for load-bearing applications. 2. Silicone sealants, known for their flexibility and resistance to weathering, making them ideal for sealing gaps and joints. 3. Acrylic adhesives, which offer good adhesion and flexibility, and are often used for bonding aluminum to other materials. 4. Epoxy adhesives, known for their high strength and resistance to chemicals, making them suitable for demanding environments. 5. Polyurethane adhesives, which provide strong bonds and excellent resistance to moisture and temperature changes. The choice of adhesive depends on factors such as the specific application, environmental conditions, and required performance characteristics.</p>

Send your message to us

Color Aluminum Sheets with Better Stocks Price in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords