Aluminum Alloy Sheets for Spaceflight - Best Price Stocks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

we are from CMNBM internatiaonal corporation ,etc.

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different alloy number and tempers , etc.

grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a. thebest-selling Competitive price

b. Frist-Class Service.

c. Shortest service.

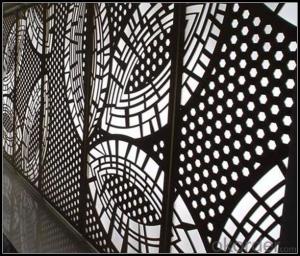

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What is the coefficient of friction for aluminum sheets?

- The coefficient of friction for aluminum sheets can vary depending on the specific conditions and surfaces involved.

- Q: How much is the price of the 6061 aluminum plate?

- The price is very transparent on the 6061 aluminium plate market!Manufacturers also have several: there are Henan, Zhejiang, Guangdong, Chongqing, Shanghai, but the prices are almost the same.There are 6061 aluminum sheet, plate, state difference; prices are not the same.6061 aluminum sheet price: national standard sheet 0.8-5.0, thickness 38/ kgGB thick plate 5.0-300, thickness 27/ kgNon standard alloy aluminum plate 20-21/ kg

- Q: What are the different types of surface treatments available for architectural aluminum sheets?

- There are several types of surface treatments available for architectural aluminum sheets, including anodizing, powder coating, and PVDF coating. Anodizing involves creating a protective oxide layer on the surface of the aluminum, providing enhanced corrosion resistance and durability. Powder coating involves applying a dry powder to the surface of the aluminum and then curing it with heat, resulting in a durable and decorative finish. PVDF coating, also known as Kynar coating, is a type of liquid coating that provides excellent weather resistance and color retention. These surface treatments can enhance the appearance and performance of architectural aluminum sheets for various applications.

- Q: What are the applications of aluminum sheets?

- Aluminum sheets have a wide range of applications across various industries. They are commonly used in the construction industry for roofing, siding, and cladding due to their lightweight, durability, and corrosion resistance. Aluminum sheets are also utilized in the automotive industry for body panels and structural components, as well as in the aerospace industry for aircraft parts. Additionally, they are commonly found in the manufacturing of household appliances, packaging materials, and electrical equipment.

- Q: Is it possible to recycle aluminum sheets while maintaining their quality?

- <p>Yes, aluminum sheets can be recycled without damaging their quality. The recycling process for aluminum is highly efficient, and it retains its properties even after multiple recycling cycles. Aluminum recycling involves melting the scrap material, which requires only 5% of the energy needed to produce new aluminum from raw materials. This process results in minimal loss of material, and the recycled aluminum maintains its strength and durability, making it suitable for various applications just like new aluminum.</p>

- Q: Are there any specific storage requirements for 101 aluminum sheets?

- Specific storage requirements exist for 101 aluminum sheets. To prevent moisture absorption and corrosion, aluminum sheets must be stored in a clean and dry area. Furthermore, a well-ventilated space is necessary to prevent the accumulation of potentially harmful gases. Proper stacking, with sufficient support and spacing, is crucial to prevent bending or deformation. Moreover, to avoid discoloration or fading, it is essential to shield the sheets from direct sunlight. A recommended practice is covering them with a suitable material, such as a plastic sheet or tarp, to offer an additional layer of protection. Ensuring appropriate storage conditions will uphold the quality and integrity of the aluminum sheets for their intended purpose.

- Q: Can aluminum sheets be recycled?

- Yes, aluminum sheets can be recycled. Aluminum is a highly recyclable material, and recycling aluminum sheets helps in conserving natural resources and reducing energy consumption compared to producing new sheets from raw materials.

- Q: Are 101 aluminum sheets readily available in the market?

- Yes, 101 aluminum sheets are readily available in the market.

- Q: Need to polish some small aluminum tubing, preferably to chrome like shine. What tools do I need? Thinking about buying 6 bench grinder, buffing? wheels and polish compound... Does it sound about right?

- I've done all sorts of tests on this topic and am using a polishing kit that was meant for plastic, but on aluminum, but after all the pads coarse to fine (wet) I found that it's better to use the last pad again but dry, rather than using the while liquid paste they propose. Polishing dry or wet makes a difference, and polishing Al is not the same as polishing a plastic. It's a tricky recipe, you can dull your Al easily, and I never got it shiny like a mirror so I want to see other answrs

- Q: Are aluminum sheets suitable for use in harsh chemical environments?

- No, aluminum sheets are not suitable for use in harsh chemical environments.

Send your message to us

Aluminum Alloy Sheets for Spaceflight - Best Price Stocks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords