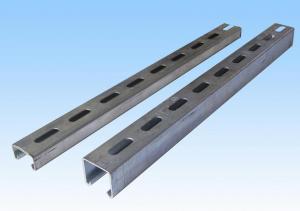

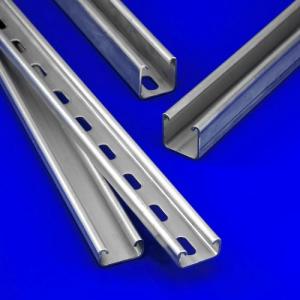

Galvanized Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meters m

- Supply Capability:

- 200000 Tons per Year m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Common Size:

Size (mm) | Thickness (mm) | Material: - Pre-Galvanized - Hot Dipped Galvanized - Back to Back available

- spring nut, bolt, nut & washer are available |

27x15 | 1.2-3.0 | |

41x21 | 1.2-2.5 | |

41x41 | 1.2-2.5 |

Hole sizes:

10*25 / 14*28 / 11*25 / 10.5*30 / 12*35mm

Our Comnany:

Octopus Metal is specialized in support channel, galvanized steel coil distribution and cable tray manufacture.

We operate 2 large-scale factories with advanced equipments. Our product have passed SGS and CE certification.

- Q: Due to the environment is not good, the original buried cable damage many times, want to use the bridge, but the overhead conditions are not allowed, the picture below is the hot water pipe, the above is the hot oil pipeline, but also over three doors more

- weak tube, line, slot construction standards and strict implementation of the construction specifications, according to construction drawings, construction manual construction The Without the signature of the general engineer, the project manager agrees and declares to the supervising company, and may not arbitrarily change the construction plan

- Q: Cable tray specifications are generally how to choose

- First, the cable bridge type and variety of options . need to shield the electrical interference cable network or protective external (such as: corrosion solution, flammable dust and other environmental impact) requirements, should use (FB) Composite anti-corrosion shielded cable tray (with cover) . strong corrosive environment should be used (F) composite epoxy resin anti-corrosion flame-retardant cable bridge. Arm, bracket also use the same material to improve the service life of the bridge and accessories, cable tray. In the easy fouling and other needs to cover the environment or outdoor places should be covered plate. . in addition to the above circumstances, according to the scene also the environment and technical requirements of the choice of tray, trough, cascade, glass anti-corrosion flame-retardant cable bridge or steel ordinary bridge. In the easy fouling and other needs to cover the environment or outdoor places should be covered plate. . in the public channel or outdoors across the road section, the bottom of the bottom of the cascade should be pad or in the use of the tray tray. Large span across the public channel, according to user requirements to improve the load capacity of the bridge or the use of rack. . large span (& amp; 3m) to use composite bridge (FB). . outdoor to use composite epoxy bridge (F).

- Q: What is the angle of the cable bridge climbing angle?

- First, a single elbow production methods: Second, multi-layer spacing and other high-angle cable bridge any angle elbow production methods: production methods and steps: the figure of the angle α with the "one" angle α value; The value is different from the b value in "one" and is the layer spacing value. . the production of the first layer of elbow: the first layer of the practice of the two elbows with the "one" elbow approach, the two elbow spacing a value determined by the scene, but to meet the requirements of the cable bending radius. . the production of the second layer of elbow: to calculate the second bridge of the first elbow positioning size e: first measure the first layer of the bridge positioning size d value, then e = d + btg1 / 2α where: According to the method of "one", the first cut of the second elbow is made α to calculate the two elbow spacing c: c The spacing of the two elbows of the first deck The second cut of the second elbow is made according to the method of "one" Calculate the compensation size h: h = 2btg1 / 2α. make the third layer elbow: the production method with the second layer elbow f = e + btg1 / 2αg = 2btg1 / 2α + c Note: multi-column equidistant bridge The method of making the elbow is the same as that of the multi-layer equidistant contour. Three, multi-layer "of the" elbow practice: and "two" is similar, but a, c, g value is equal to the cut of the two α angle on both sides of the bridge

- Q: What is the national standard of the thickness of the bridge?

- Positive pole connected to the engine negative pole of the car beam or the engine any one place

- Q: What is the safety distance between the bridge and the bridge?

- Because the strong current generated by the electromagnetic field will interfere with the weak line.

- Q: Cable tray elbow to know the angle and the width and height of the bridge how to calculate the problem of cutting more

- There are ready to buy ah! What about doing? Waste of manpower, material, time.

- Q: Does the weak and fire can share a cable tray?

- Please refer to the following code: Wire and cable for the transmission of electrical (magnetic) energy, information and the realization of electromagnetic energy conversion wire products, generalized wire and cable is also referred to as cable, narrow cable refers to the insulated cable, which can be defined as: One or more insulated cores, and their respective possible cladding, the total protective layer and the outer sheath, and the cable may have additional uninsulated conductors. For the transmission of electrical (magnetic) energy, information and the realization of electromagnetic energy conversion wire products. Wire, cable, cable bare wire, including bare copper wire, bare aluminum wire, copper clad steel wire, copper clad aluminum wire, other bare wire bare wire, bare wire, bare copper wire, bare aluminum wire, copper clad steel wire, copper Insulated wire, insulated wire, insulated wire, Winding wire, Wiring set, Installation of electric wire, Telephone cord, Telephone cord, Telephone wire Cable coaxial cable, coaxial cable, RF cable, high-frequency coaxial cable dedicated cable, including communication and electronic network with the use of high-frequency coaxial cable, Cable, power cable, traffic signal cable, audio and video power supply with fire-retardant soft cable, submersible motor waterproof rubber flexible cable, other dedicated cable dedicated wire, dedicated cable, communication cable, electronic network cable, power cable, traffic signal Dedicated cables, Flame-retardant flexible cables for audio and video power supply, Waterproof rubber sheathed cables for submersible motor Electronic components Leaded components Lead wire Other wire and cable

- Q: How the bridge slot is connected to the ladder

- Press the remote control can be switched button, (that is, whether there is no picture in the painting button), press this button to achieve picture-in-picture function, but also to achieve whether the painting in the switch, while watching by painting , Only show the normal big screen so far.

- Q: What is a cable tray? What is the purpose of the cable tray?

- 214 provides the same path may interfere with the requirements of the line can be laid in the same metal pipe or metal box

- Q: Cable bridge 2 × (300 × 150) is what

- According to the outer diameter of the cable to customize the processing

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | |

| Main Markets | North America South America Southeast Asia Africa Mid East Eastern Asia South Asia |

| Company Certifications | ISO14001:2004 ;ISO9001:2008 ;The SGS Certifications Of Cable Tray System |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Guangzhou,Shenzhen |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, German, French |

| b) Factory Information | |

| Factory Size: | 50,000-100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Galvanized Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meters m

- Supply Capability:

- 200000 Tons per Year m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches