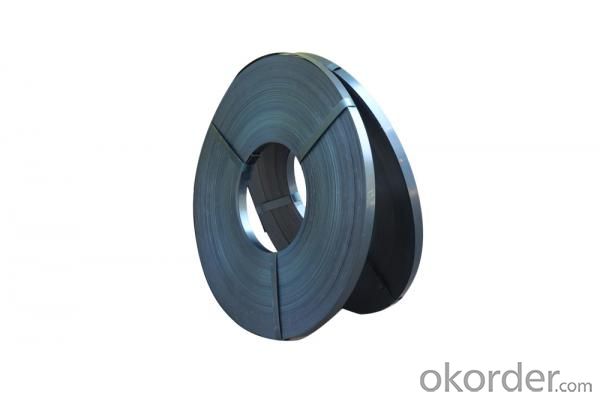

black/blue/galvanized steel packing strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

[Sort of steel packing strips]:

(1) White steel packing strips

(2) Blue steel packing strips

(3) Paintbaked steel packing strips(black,green,gray,yellow etc.)

[Mechanical properties]:

(1)Ordinary steel strips():

tensile strengthσb≥58-78Kg/mm2(580-780Mpa),elongation3%-5%.

(2)Ordinary steel strips():

tensile strengthσb≥78-90Kg/mm2(780-900Mpa),elongation3%-5%.

(3)High quality steel strips:

high high intesity,good capability,bearing impact.tensile strength: 90-100Kg/mm2 (900-1000Mpa) , elongation5%-10%.

[Specification]:

BWG28×3/8'' , 1/2'' ,5/8'' ( 0.36mm×9.5mm ,12.7mm ,16mm)

BWG27×3/8'' , 1/2'' ,5/8'' (0.40mm×9.5mm , 12.7mm ,16mm)

BWG26×1/2'' , 5/8'' , 3/4'' (0.45mm×12.7mm , 16mm , 19mm)

BWG25×1/2'' , 5/8'' , 3/4'' (0.50mm×12.7mm , 16mm , 19mm)

BWG24×1/2'' , 5/8'' , 3/4'' (0.55mm×12.7mm , 16mm , 19mm)

BWG23×1/2'' , 5/8'' , 3/4'' (0.60mm×12.7mm , 16mm , 19mm)

BWG22×3/4'' , 1'' , 5/4'' ( 0.70mm×19mm , 25.4mm, 32mm)

BWG21×3/4'' , 1'' , 5/4'' (0.80mm×19mm , 25.4mm, 32mm)

BWG20×3/4'' , 1'' ,5/4 '' , (0.90mm×19mm , 25.4mm , 32mm)

BWG19×3/4'' , 1'' , 5/4'' (1.0mm×19mm , 25.4mm, 32mm)

[Others]:

We can produce special specification as per customers request,and we can make the edge smoother of the steel packing strips.

Specifications

steel packing stripBlack or galvanized

Material:Q195 or Q235

Package:50kgs/coil,or as customer request

The steel packing strip has the following advantage:

Surface treatment | Black painted wax,Blue or Galvanized surface |

Size | thickness:0.3mm-1.0 mm,width:12.7-32mm or any width as your request.

|

Package | Ribbon & Oscillated,50kgs/coil,or as customers requirements

|

- Q: What measures can be wrought iron and cast iron welding together, as simple as possible.

- Can be used in gas welding welding, is oxygen - acetylene flame welding

- Q: What is the difference between pig iron and cast iron?

- Cast iron: the need to control the composition of alloy elements, adding a certain amount of. At the same time the need to control the solidification process and heat treatment, control of graphitization process, meet the certain organization, to achieve a certain mechanical properties of nodular cast iron. We often hear is the addition of a rare earth magnesium ball nodulizer, and malleable cast iron by white cast iron by annealing.

- Q: The difference between iron and wrought ironDon't say one is raw, the other is ripe

- Generally less than 0.2% carbon content that wrought iron or iron, the content of 0.2-1.7% in the steel, content of more than 1.7% is iron. Iron soft, good plasticity, easy deformation, strength and hardness were lower, not widely used; iron carbon, hard and brittle, almost no plastic.In addition to talk about discrimination: the distinction between pig iron and wrought iron with carbon content of course can not distinguish in life, because you can't see it. So we can only watch and ear differentiation:1, see: Iron fracture is rough, showing a bead (for the sake of coarse grain iron), and wrought iron fracture is generally more smooth; if this is a new fracture, but also to see the dark and shiny born iron wrought iron lighter; iron fracture is generally irregular, because it is very crisp, mostly to be interrupted, (which is processed, it is very flat and wrought iron) must not be interrupted, mostly by certain way processed separately, so the fracture is generally neat fracture; if it is cutting, that is cooked pig iron is iron. Can not be cutting; iron surface will not have pores, familiar iron porosity; if a piece of iron is a significant deformation (bending) that is wrought iron because of poor plasticity, not so true to the deformation, bending, or broken or obvious The crack will not be very large and there are some details which can not be made clear. It is necessary to have some experience2, listen: Pig beating sound boring, beating sound loud. Wrought iron3, if you have a file in the hand, can be used to file to see finish can also make a judgment from the file down the iron can also be seen, but this is beyond your request, it can be done in the factory.4, if placed in the grinder grinding, see iron spark from a judge or iron wrought iron, but this is to be in the factory in order to do it.About it, may not be full, but through these methods, generally can distinguish pig iron or wrought iron.

- Q: Why is cast iron used for motor end caps? Is regular iron OK?

- Cast iron (Sheng Tie) is low in toughness, good in casting water flow, easy to cast, simple in production process, low in cost, and fully meets the requirement of use.If the use of ordinary iron (Shu Tie), molten iron is too soft, sticky, poor liquidity, complex production processes, high cost, it will not choose Shu Tie casting end cover,

- Q: How can I defrost it with pig iron?

- The thermal conductivity of iron, promote the ice temperature and ice water exchange outside = solid, it consists of H2O or O2 will contact the oxygen because of the iron oxidation longevity hot, so when it is exposed to the H2O, is also the time when water will be oxidized, because water is oxygen atoms, so, heat in order to make the ice melt

- Q: What is the difference between pig iron and cast iron?

- Pig iron is cast iron: carbon content is greater than 2.1%. White cast iron is used in steel making; grey cast iron is used for casting; ductile iron is good in its strength, plasticity and toughness because of its spherical arrangement of graphite; it can make mechanical parts.

- Q: What is the general material of pig iron casting mould, as well as the technical points and matters needing attention in the process of production

- The main product mould and casting process to set pattern, Aluminum Alloy die, die, die cast, resin mold

- Q: What's the difference between pig iron and nickel iron?

- An iron carbon alloy with a high carbon content; a low carbon steel containing nickel iron. Their performance is very different, nickel iron should belong to alloy steel.

- Q: Excuse me. What kind of pig iron into wrought iron process. Urgent need!

- Comparison of pure iron with iron and refined. The carbon content below 0.02%, also called the wrought iron. Iron is very soft, good ductility, can pull into a wire, easily forged and welded. Generally less than 0.02% carbon content called wrought iron or iron, content in 0.02-2.11% steel, called iron content in 2.11-6.69%.

- Q: Wrought iron and steel which is more hard

- The difference between iron and steel: iron into pig iron and wrought iron. Wrought iron, steel and cast iron is an alloy of iron and carbon with the carbon content difference. Generally less than 0.2% carbon content that wrought iron or iron, the content of 0.2-1.7% in the steel, is iron content of more than 1.7%. Soft wrought iron, good plasticity, easy deformation, strength and hardness were lower, not widely used; iron carbon, hard and brittle, almost no plastic; steel pig iron and wrought iron with two kinds of advantages, widely used for human.

Send your message to us

black/blue/galvanized steel packing strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords