Zinc Coated Galvanized Steel Coil of GI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

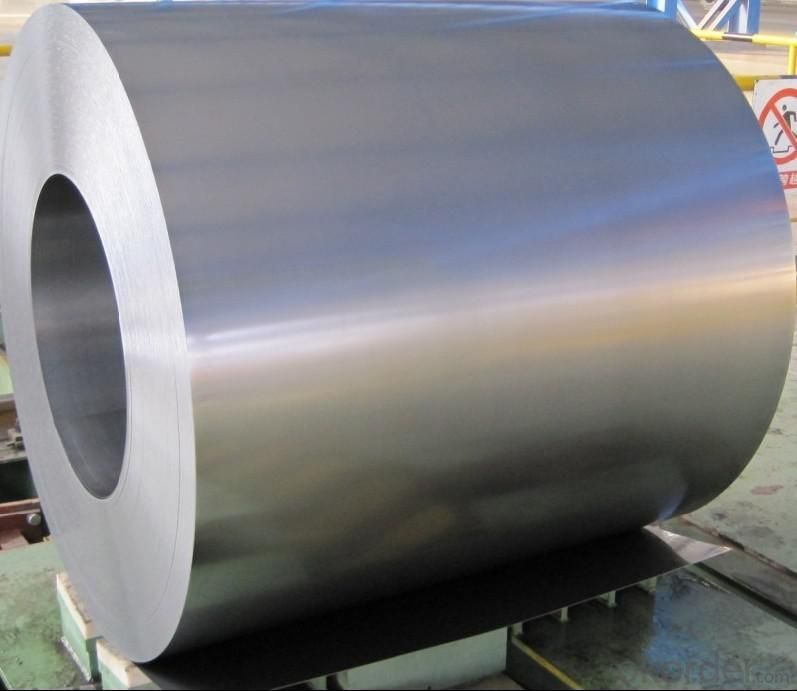

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

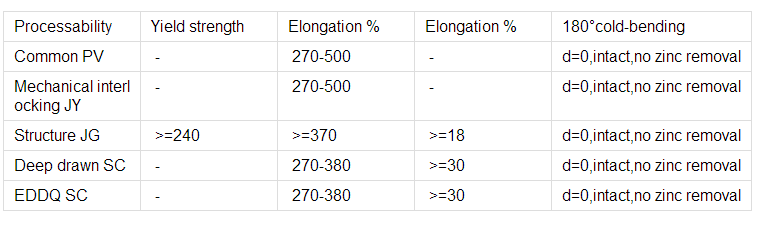

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of construction cranes?

- Steel coils are used in the manufacturing of construction cranes to form the structural components, such as the boom, mast, and jib. These coils are processed and shaped through a series of cutting, bending, and welding techniques to create the strong and durable framework necessary for the crane's operation.

- Q: What are the different methods of laminating steel coils?

- There exist multiple techniques for laminating steel coils, each possessing its own advantages and applications. The prominent techniques encompass hot rolling, cold rolling, and continuous annealing. Hot rolling involves heating the steel above its recrystallization temperature and subsequently passing it through a sequence of rollers to generate thin sheets or coils. This method is frequently employed for the mass production of steel with a uniform thickness and surface finish. Structural applications such as construction and automotive manufacturing commonly utilize hot rolled steel coils. In contrast, cold rolling entails passing the steel coil through a set of rollers at room temperature. This process not only reduces the thickness of the steel but also enhances its surface finish and mechanical properties. Industries requiring high precision and quality, such as appliance manufacturing, electrical equipment, and automotive components, typically employ cold rolled steel coils. Continuous annealing represents an alternative approach to laminating steel coils. It involves heating the steel coil to a specific temperature and gradually cooling it in a controlled environment. This procedure aids in alleviating internal stresses and enhancing the mechanical properties of the steel, such as strength and ductility. Continuous annealing is frequently utilized to produce high-quality steel coils for applications necessitating superior surface finish and formability, like automotive body panels and household appliances. Additional less prevalent methods of laminating steel coils comprise electro-galvanizing and hot-dip galvanizing. Electro-galvanizing encompasses coating the steel with a zinc layer through an electroplating process, while hot-dip galvanizing entails immersing the steel coil in molten zinc. These techniques primarily serve corrosion protection purposes and are commonly employed in the construction industry, particularly for outdoor structures and infrastructure. To summarize, the various techniques for laminating steel coils encompass hot rolling, cold rolling, continuous annealing, electro-galvanizing, and hot-dip galvanizing. Each approach offers distinct advantages and is selected based on the specific requirements of the application.

- Q: I want to know the special characters or the advantages of the corton steel. In what cases it is recommended to use?Thank you.

- *It is Corten steel.Grade A B. *Weathering steel, best-known under the trademark COR-TEN steel, is a group of steel alloys which were developed to obviate the need for painting, and form a stable rust-like appearance if exposed to the weather for several years. United States Steel Corporation (USS) holds the registered trademark on the name COR-TEN. Although USS sold its discrete plate business to International Steel Group (now Arcelor-Mittal) in 2003, it still sells COR-TEN branded material in strip-mill plate and sheet forms. In some areas it may be known without the hyphen as Corten steel. The original COR-TEN received the standard designation A242 (COR-TEN A) from the ASTM International standards group. Newer ASTM grades are A588 (COR-TEN B) and A606 for thin sheet. All alloys are in common production and use. It is a weather-resistant steel which is used in containers and hot flue gas line. The American Corten A Steel has a composition of C, 0.12; Si, 0.5; Cu, 0.5; Cr, 0.8; P, 0.1 and Mn, 0.5%. Although the tensile strength is less than 494 MPa the yield is in the region of 371 MPa. The combination of copper and phosphorus also increases the resistance to atmospheric corrosion which is important when thinner plates are used. The original steel A suffers a decrease in yield strength and notch ductility in thickness over 25 mm, to overcome which Corten B was developed-C 0.14; P 0.04; Mn 1.1; Cr 0.5; Cu 0.4; V 0.1; Bol Al 0.02. *COR-TEN A applies to plates up to 12.5mm in thickness, COR-TEN B applies to plates up to 50mm in thickness. *It has been used in bridge and other large structural applications such as the New River Gorge Bridge, the newer span of the Newburgh-Beacon Bridge, and the creation of the Australian Centre for Contemporary Art (ACCA). It is very widely used in marine transportation, in the construction of shipping containers.

- Q: Is Stainless steel called that because.....a. Its stains lessORb. Its virtually stainless (it can't stain).Lol do you know the correct answer?????

- a. is the correct answer. It will still show tea and coffee stains. I find using baking soda is a good way to clean it and freshens the drains of the sinks as well. If cleaning your refrigerator a glass cleaning spray works well, just be sure to dry it thoroughly.

- Q: What are the dimensions of steel coils used in the energy sector?

- The dimensions of steel coils used in the energy sector can vary depending on the specific application and requirements. However, commonly used dimensions for steel coils in the energy sector range from 0.5mm to 5.0mm in thickness, with widths typically ranging from 600mm to 2000mm. The diameter of the coil can vary as well, with commonly used sizes ranging from 1000mm to 2200mm. These dimensions are chosen to ensure the coils can be easily transported, processed, and utilized in various energy sector applications such as power plants, oil and gas pipelines, and renewable energy projects. It is important to note that these dimensions are not fixed and can be customized based on specific project requirements.

- Q: How are steel coils used in the manufacturing of construction reinforcement bars?

- Steel coils are used in the manufacturing of construction reinforcement bars by being processed through a series of rolling mills. These coils are first uncoiled and then heated to a high temperature, allowing them to be easily shaped and molded into the desired bar shape. The coils are then passed through a series of rollers that gradually reduce their thickness and increase their length. This process gives the steel bars the necessary strength and durability to be used as reinforcement in construction projects.

- Q: How are steel coils inspected for straightness using laser alignment?

- Steel coils are inspected for straightness using laser alignment through a precise and automated process. Laser alignment technology offers a non-contact method to measure the straightness of steel coils with high accuracy and efficiency. Firstly, the steel coil is placed on a conveyor system that moves it through the inspection area. As the coil passes through, a laser alignment system is set up to emit a laser beam across the width of the coil. This laser beam acts as a reference line for the straightness measurement. The laser alignment system consists of a laser emitter and a receiver unit. The emitter projects a laser beam that is perfectly straight and parallel to the desired alignment. The receiver unit, placed on the opposite side of the coil, captures the laser beam and analyzes its position. As the coil moves through the inspection area, the receiver unit determines the deviation of the laser beam from the desired straight line. This deviation is calculated by analyzing the position of the laser beam at multiple points along the coil's width. The laser alignment system is connected to a computerized control system that processes the data received from the receiver unit. The control system performs complex calculations to determine the straightness of the coil based on the laser beam's position. Any variations or deviations from the desired straight line are recorded and analyzed by the control system. The inspection data can be presented in real-time, allowing operators to monitor the straightness of the steel coil during the inspection process. Using laser alignment for steel coil inspection offers several advantages. It provides highly accurate measurements, ensuring that even minor deviations from straightness are detected. The non-contact nature of laser alignment eliminates the need for physical contact with the coil, reducing the risk of damage or contamination. Additionally, the automated process saves time and increases efficiency compared to manual inspection methods. Overall, laser alignment technology is a reliable and efficient method for inspecting the straightness of steel coils. It ensures that only coils meeting the required straightness criteria are passed, contributing to the quality control of steel manufacturing processes.

- Q: nylon sounds alot better but i want to keep the acoustic i have now. Is it proper to put nylon on an acoustic guitar meant for steel strings?

- As others have said, it is not recommended because the steel-string neck is meant to handle the tension of steel strings, and nylon strings have much less tension. It won't do any immediate damage, especially if you loosen your truss rod a full turn or two to compensate. But if you keep the nylon strings on for too long your neck may twist or warp irreversibly. I don't recommend doing it, but if you want to try it anyway, get nylon strings with ball ends (Martin makes Darco strings with ball ends, and there are also Black Diamond strings with ball ends). Putting nylon strings on a steel-string guitar is not nearly as bad as putting steel strings on a nylon-string guitar -- whatever you do, don't do that!

- Q: How are steel coils used in the production of storage tanks?

- Steel coils are used in the production of storage tanks as they provide the necessary strength and durability required for containment and storage of various substances. These coils are rolled into cylindrical shapes and welded together to form the tank's body, ensuring a tight and secure structure. Additionally, the steel coils can be coated or treated to provide corrosion resistance, further enhancing the tank's longevity and suitability for storing liquids or gases.

- Q: I need new sprockets on my GSX-R1, I've heard that alumnium sprockets wear out twice as fast as steel and the difference is not noticable

- I would stick with what was on the bike steal front/rear and same chain size. I'm not crazy about changing the gearing, but it's definately important to stick to the stock stuff. steal lasts longer and a stock size chain is likely to last longer. I got 25.5k miles out of my stock chain/sprockets on my RC51. I went with stock gearing vortex steel front and JT steel rear and the top 530 EK chain. I expect that I will get another 25k miles before the set is changed again. I'm so used to the tall first gear, and don't need quicker accelleration. I also don't want to mess up the displayed road speed and recorded miles.

Send your message to us

Zinc Coated Galvanized Steel Coil of GI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords